Why Most Sublimation Sellers Underprice Without Realizing It

If you’ve ever thought, “I’m getting orders… but where is the profit?” you’re not alone.

Many sublimation sellers stay busy but struggle to grow because their pricing quietly eats their margin.

Here’s why it happens:

- Ignoring labor – You count materials but forget your time. Even 15 minutes per shirt adds up fast.

- Underestimating ink usage – Full front designs use far more ink than small logos.

- Not factoring overhead – Electricity, equipment wear, packaging, and workspace costs are real.

- Copying competitor pricing – You don’t know their costs, volume, or margin targets.

- Emotional pricing decisions – You price based on what “feels fair” instead of what’s sustainable.

The result? Sales without stability.

You don’t need to guess.

You need a formula.

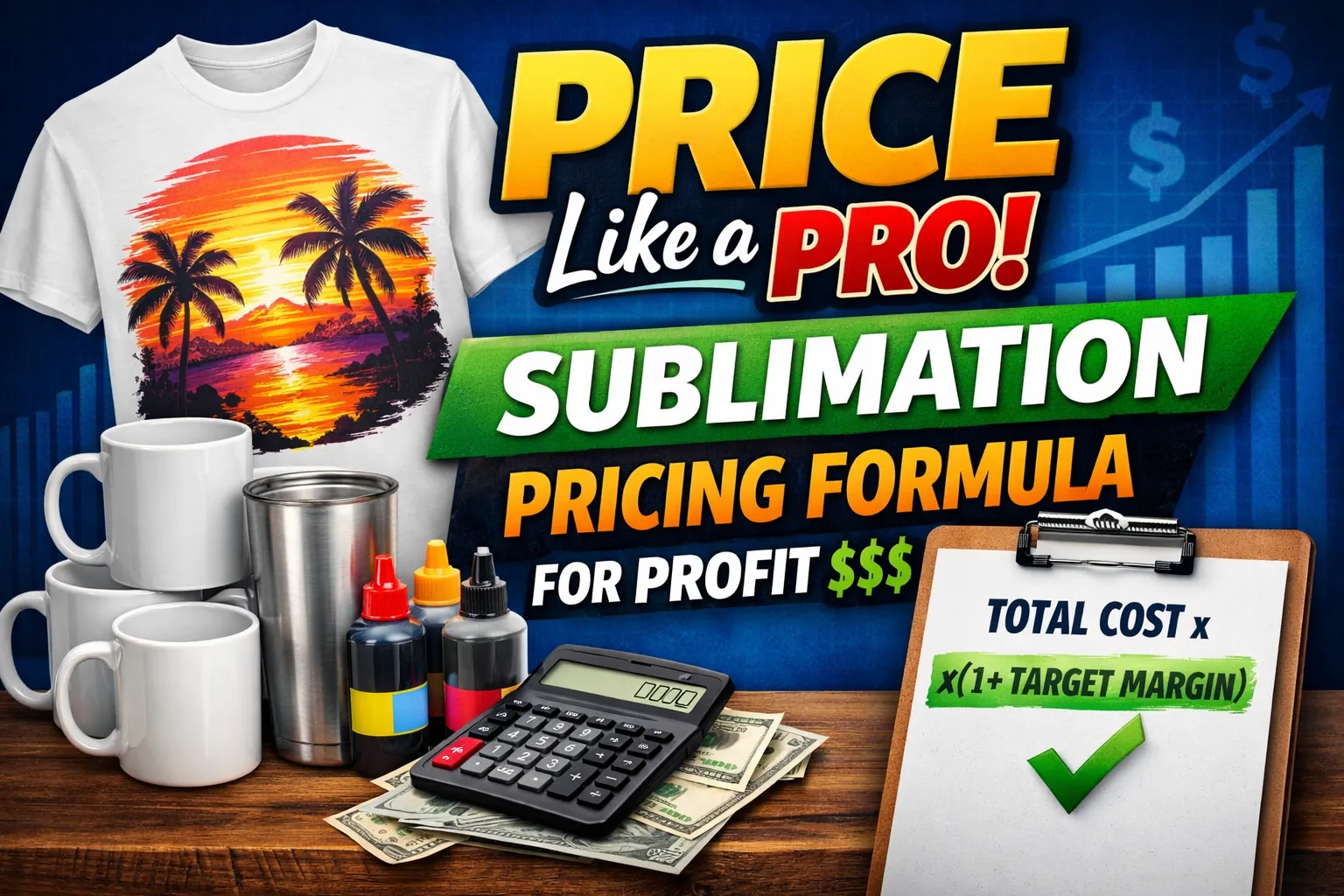

The Exact Sublimation Pricing Formula (Simple and Repeatable)

Here’s the formula that removes guesswork:

Selling Price = Total Cost × (1 + Target Margin)

It works for shirts, mugs, tumblers, panels, and any sublimation product.

What Counts as Total Cost

Your total cost per item must include:

- Blank cost

- Ink

- Transfer paper

- Labor

- Packaging

- Overhead

If any of these are missing, your margin calculation is inflated.

Even small overlooked costs can shrink yearly profit significantly.

What Is a Target Profit Margin?

Margin is the percentage of revenue that remains after expenses.

Margin and markup are not the same.

- Markup is added on top of cost.

- Margin is calculated from the final selling price.

Margin is safer because it protects your profit percentage regardless of cost changes.

Margin formula:

Margin (%) = Profit ÷ Revenue × 100

Using margin ensures your pricing remains stable even when suppliers increase prices.

Try the Formula Instantly (Interactive Calculator)

Understanding the pricing formula is one thing. Applying it accurately every time is another.

Instead of calculating everything manually, you can use the interactive pricing calculator below to test different cost and margin scenarios in seconds.

Enter your blank cost, ink usage, labor, overhead, quantity, and target profit margin. The calculator will instantly show:

- Cost per item

- Total production cost

- Recommended selling price

- Profit per item

- Total profit for the batch

This helps you:

- Avoid underpricing

- Test bulk discounts safely

- Adjust for rising material costs

- Compare different product types

Use it before launching a new product or quoting a custom order.

Now enter your numbers and see your real margins.

Step-by-Step: How to Price Any Sublimation Product

This method works for any item you sell.

Step 1: Calculate True Cost Per Item

Example for a custom shirt:

- Blank shirt: $4

- Ink + paper: $1.20

- Labor: $2

- Packaging + overhead: $0.80

Total cost = $8 per shirt.

That number is your foundation.

Step 2: Choose a Target Margin

General guidance:

- 40–50% for simple, repeatable items

- 50–65% for custom or personalized products

- 60%+ for low-volume or specialty work

Your margin should reflect effort, risk, and customization level.

Step 3: Apply the Formula

Let’s say your cost is $8 and you want a 60% margin.

Selling Price = 8 × (1 + 0.60)

Selling Price = 8 × 1.60

Selling Price = $12.80

Round appropriately for your market, maybe $13 or $14.

Now your pricing protects your target margin.

Step 4: Test Bulk Scenarios

If someone orders 50 shirts:

- Your labor per shirt may decrease.

- Ink waste may drop.

- Packaging cost per unit may shrink.

Recalculate using the updated cost per shirt.

Bulk orders should still protect margin, even if slightly reduced.

How Much Should You Charge for Sublimation Shirts?

This depends on design size, cost structure, and margin target.

Small Chest Logo Example

- Cost per shirt: $7

- Target margin: 50%

- Selling price: $10.50–$12

Full Front Design Example

- Cost per shirt: $9

- Target margin: 60%

- Selling price: $14.50–$16

Bulk Order Example (50 Shirts)

- Adjusted cost per shirt: $7.50

- Target margin: 50%

- Selling price: $11–$12

Here’s a quick comparison:

| Cost Per Shirt | Selling Price | Margin |

|---|---|---|

| $7 | $12 | ~42% |

| $8 | $14 | ~43% |

| $9 | $16 | ~44% |

| $8 | $13 | ~38% |

If your margin drops too low, your pricing needs adjustment.

Sublimation Profit Margin Benchmarks by Product Type

Not all products perform the same.

| Product Type | Avg Cost | Common Price | Typical Margin |

|---|---|---|---|

| Mugs | $5–6 | $12–15 | 45–60% |

| T-Shirts | $6–9 | $18–25 | 40–60% |

| Tumblers | $9–12 | $25–35 | 50–65% |

| Phone Cases | $4–6 | $15–22 | 55–70% |

| Photo Panels | $7–10 | $20–30 | 45–60% |

If your numbers fall below these ranges, review your cost inputs or pricing formula.

Common Pricing Mistakes That Destroy Profit

Most pricing problems come from small oversights.

- Ignoring labor completely

- Pricing based on competitors

- Offering discounts without recalculating margin

- Forgetting reprint costs

- Not adjusting pricing for larger design coverage

Correct these and profit improves immediately.

Wholesale Pricing Formula for Sublimation Businesses

Wholesale pricing requires a different approach.

Retail margins may be 50–65%.

Wholesale margins may drop to 30–45%, depending on volume.

Minimum acceptable margin depends on:

- Production efficiency

- Volume commitment

- Payment terms

Bulk break-even example:

If your cost is $8 and you accept a 35% margin:

Selling Price = 8 × 1.35

Selling Price = $10.80

Ensure that lower margin still covers risk and overhead.

How to Adjust Pricing When Costs Increase

Costs change. Your pricing must adapt.

Blank price increases by $0.50

Ink price increases by $0.20

Shipping rises unexpectedly

A $1 cost increase on 500 shirts per year equals $500 in lost profit if unadjusted.

Recalculate immediately when:

- Supplier prices change

- Shipping rates increase

- Production time changes

Small adjustments protect long-term income.

If you’re unsure how much ink really costs per design, use our detailed sublimation cost estimator to calculate your true production expenses.

Should You Ever Lower Your Prices?

Lowering prices can make sense if:

- You’re clearing inventory

- You’re running a short-term promotion

- You’re increasing volume strategically

It damages brand value when:

- It becomes permanent

- It’s based on competitor panic

- It drops margins below sustainability

Always test discount scenarios before committing.

Using a Calculator to Protect Your Margins

Manual math works, but calculators reduce error.

Use a pricing calculator when:

- Launching new products

- Testing bulk discounts

- Adjusting for cost increases

- Comparing product profitability

Use a T-shirt-specific calculator when:

- Design coverage affects ink usage

- You need margin-based recommended pricing

- You’re pricing multiple shirt sizes or runs

Testing scenarios before production prevents expensive mistakes.

Want to test different pricing scenarios instantly? Try our interactive sublimation pricing calculator to protect your margins before quoting customers.

Frequently Asked Questions

How much profit should I make on sublimation products?

Most small businesses aim for 40–65% depending on product complexity and customization.

What is a good profit margin for T-shirts?

A healthy range is typically 40–60%, depending on design size and production efficiency.

Should I include my time in pricing?

Yes. Ignoring labor reduces long-term sustainability.

Is markup the same as margin?

No. Margin is based on final selling price, while markup is added to cost.

How do I price bulk sublimation orders?

Lower margin slightly for volume, but ensure total profit remains strong and sustainable.