Estimate your true sublimation project cost, profit, and margin in seconds.

Enter your material cost, ink and paper usage, labor, overhead, selling price, and quantity. The calculator instantly shows total cost, revenue, profit, and margin percentage so you can price confidently and avoid undercharging.

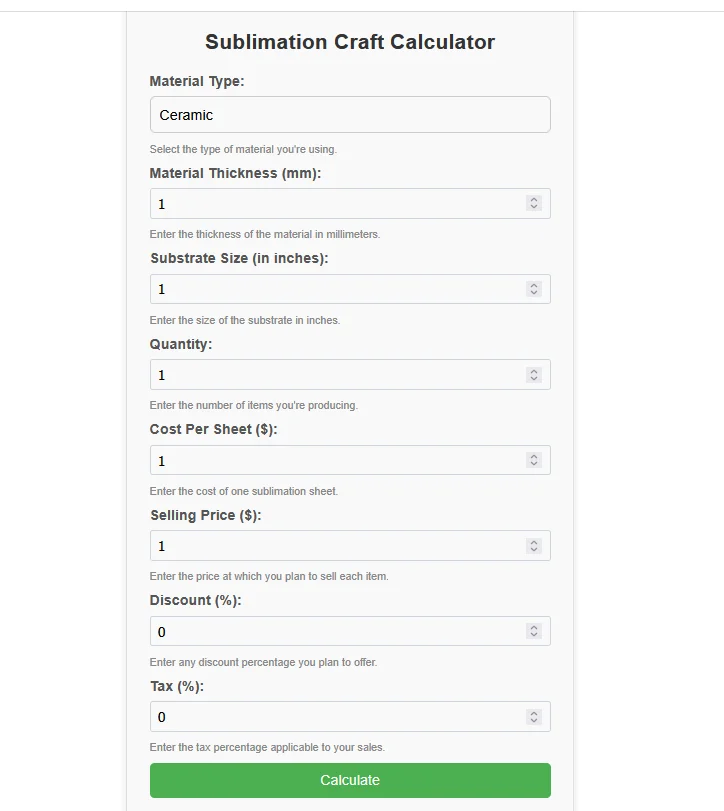

Sublimation Craft Calculator

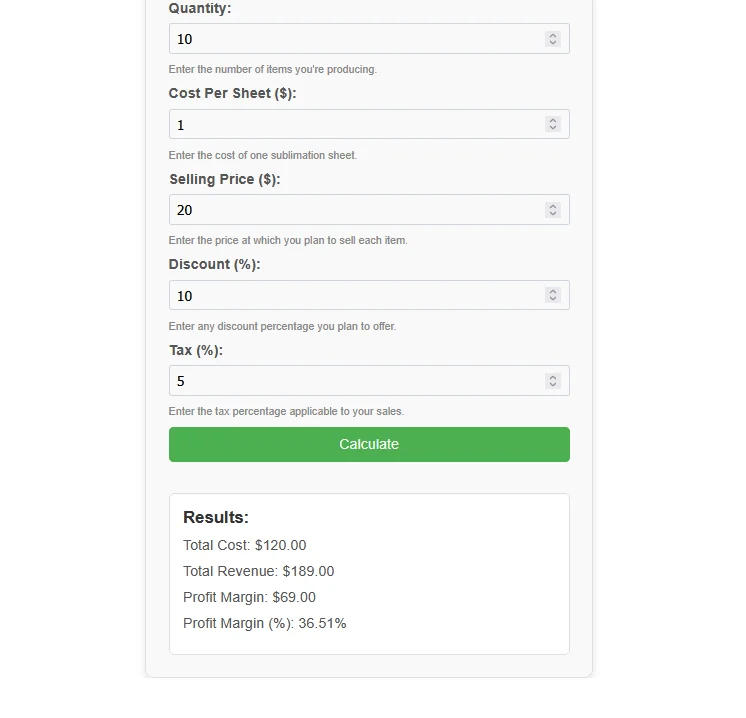

Select the type of material you’re using. Enter the thickness of the material in millimeters. Enter the size of the substrate in inches. Enter the number of items you’re producing. Enter the cost of one sublimation sheet. Enter the price at which you plan to sell each item. Enter any discount percentage you plan to offer. Enter the tax percentage applicable to your sales.Results:

Total Cost: $0.00

Total Revenue: $0.00

Profit Margin: $0.00

Profit Margin (%): 0.00%

Calculator Inputs

Enter accurate values for best results.

Material Cost per Item ($)

Cost of blank (mug, shirt, tumbler, etc.)

Ink + Paper Cost per Item ($)

Estimated ink usage plus transfer paper

Labor Cost per Item ($)

Your time per item (recommended even for solo businesses)

Overhead per Item ($)

Electricity, equipment wear, workspace allocation

Selling Price per Item ($)

Planned retail or wholesale price

Quantity

Number of items in this batch

Results Display

The calculator generates:

- Total Cost

- Total Revenue

- Total Profit

- Profit Margin (%)

How the Calculator Works

The calculator uses standard cost accounting formulas:

Total Cost (per item)

Material + Ink/Paper + Labor + Overhead

Total Batch Cost

Total Cost × Quantity

Total Revenue

Selling Price × Quantity

Profit

Revenue – Total Batch Cost

Profit Margin (%)

(Profit ÷ Revenue) × 100

Example Calculation

Example for a custom mug batch:

- Material: $2.50

- Ink + Paper: $0.75

- Labor: $2.00

- Overhead: $0.50

- Selling Price: $12

- Quantity: 25

Per-item cost = $5.75

Batch cost = $143.75

Revenue = $300

Profit = $156.25

Margin ≈ 52%

Tools like the Sublimation Craft Calculators from Subli Genius Print are designed specifically for these workflows.

What Should Be Included in “Total Cost”

To avoid underpricing, include:

- Blank product cost

- Ink usage (based on design size)

- Transfer paper

- Packaging

- Labor time

- Electricity

- Equipment wear

If any of these are excluded, margin results will be inflated.

When to Use This Calculator

Use it when:

- Pricing new products

- Testing bulk order discounts

- Evaluating wholesale offers

- Adjusting prices after supplier increases

- Comparing profit across product types

If you’re managing multiple variables, combining this with a broader sublimation cost estimator can save serious time.

If not, the price needs adjustment.

Tools like a dedicated sublimation pricing calculator make it easier to test prices before committing to them.

FAQs

Remember, pricing is a dynamic process. As your skills grow, or material costs fluctuate, revisit your calculations with the help of your trusty calculator.

Let Subli Genius Print be your partner in this journey, providing tools and resources to unlock your sublimation business potential.