7 Pro Tips for Mastering Heat Press Temperature for Sublimation

Get expert advice on finding the right heat press temperature for your sublimation projects! Learn how to optimize your settings for perfect results every time.

As a passionate sublimation enthusiast, I’ve discovered that achieving stunning and vibrant sublimation prints combines science and art. Heat press temperature is a critical factor in this equation.

To ensure bright, durable sublimation prints on polyester fabrics every time, it’s important to adhere to the ideal temperature range of 380°F (193°C) to 400°F (204°C) and follow the manufacturer’s recommendations for ink and paper.

Heat Press Temperature for Sublimation

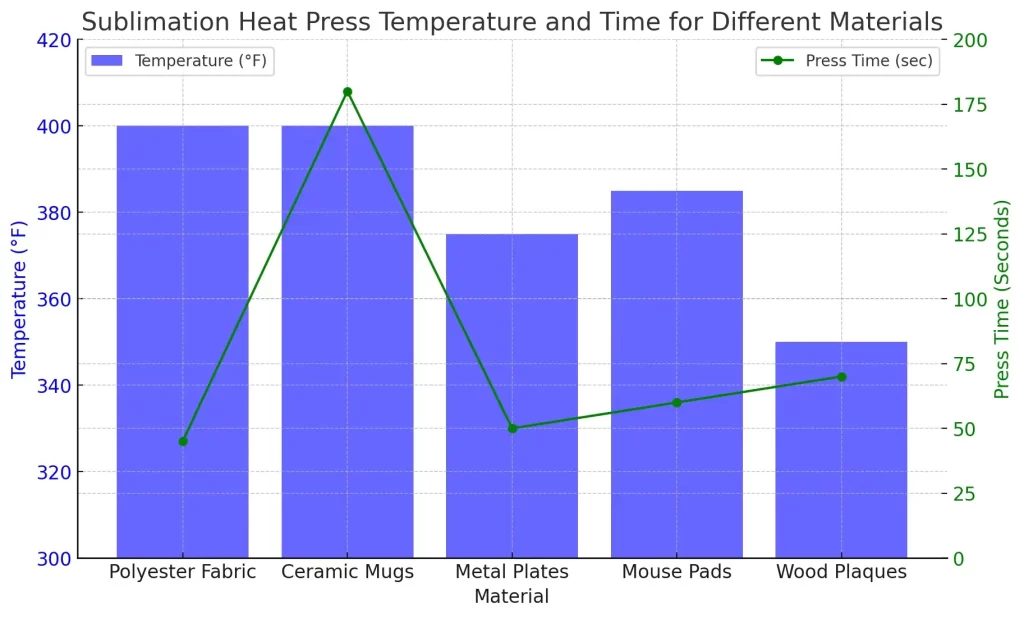

The ideal heat press temperature for sublimation is usually between 375 and 400°F (190 and 204°C), with a pressing time of 30-60 seconds depending on the material. Always check the specific recommendations for your blank product, such as mugs, shirts, or mousepads, to ensure the best results.

Heat Press Temperatures and Times:

| Substrate | Temperature (°F) | Time (seconds) |

|---|---|---|

| Polyester Fabric | 375°F to 400°F | 40 to 75 seconds |

| Ceramic Mugs | 375°F to 400°F | 180 to 240 seconds |

| Metal Panels | 400°F to 425°F | 60 to 90 seconds |

| Glass | 400°F to 425°F | 300 to 420 seconds |

Table of temperature chart:

| Substrate | Press Time (seconds) | Temperature (°F) | Pressure (psi) |

|---|---|---|---|

| Ceramic Mugs | 150-210 | 370-400 | 40 (medium) |

| Metal | 60-80 | 375-400 | 40 (medium) |

| Ceramic & Glass Tile | 300-720 | 380-400 | 40 (medium) |

| Polyester Fabric | 45 seconds | 380-400 | 40 (medium) |

Tips

- Ceramic Mugs: Start timer countdown when mug and mug-press are up to temp. Remove transfer once mug is cool.

- Metal: Use heat-resistant tape around the edge of the transfer and a non-stick sheet when possible.

- Ceramic & Glass Tile: Press tiles from the back (transfer side down) into a silicone pad. Use caution with pressure to prevent breakage.

- Polyester Fabric: For brighter colors, use a high white-point polyester fabric with a tight weave.

| Substrate | Press Time (seconds) | Temperature (°F) | Pressure (psi) |

|---|---|---|---|

| Square Sequins Pillow Case | 45-55 | 380-400 | 40 (medium) |

| Soft L’INK T-Shirts | 35-40 | 380-400 | 40 (medium) |

| Vapor Apparel | 45-55 | 380-390 | 40 (medium) |

| UNISUB Products | 60 | 380-400 | 40 (medium) |

| FR Plastic | 45-90 | 380-400 | 40 (medium) |

Tips

- Square Sequins Pillow Case: Use a pressing pillow and Non-stick sheet for best results. The cloth side can also be used for sublimation.

- Soft L’INK T-Shirts: Pre-press shirt to eliminate moisture. Tack the transfer and use a Non-stick sheet to avoid ghosting.

- Vapor Apparel: See www.Vaporapparel.com for more information.

- UNISUB Products: Remove any plastic coating if present. Peel transfer away as soon as possible.

- FR Plastic: Use a Non-stick sheet when possible. Remove any plastic coating if present.

1. The Crucial Role of Temperature

The activation of the sublimation ink and proper bonding with the material is ensured by the role of temperature in sublimation printing. If the print is too low, it may appear faded; if it is too high, it can scorch the surface or blur the design. Consistent and precise heat settings are essential for vibrant and durable results.

2. Optimal Starting Point

Begin by determining the recommended temperature range for the type of substrate you’re using. This information can usually be found on the manufacturer’s website or packaging. As a general rule of thumb, the initial temperature setting should be at the lower end of the recommended range.

3. Gradual Increase Technique

Gradual temperature increase is a technique that often yields fantastic results. Start from the bottom of the recommended range and gradually increase the temperature in small increments (about 5-10 degrees Fahrenheit) to achieve the desired outcomes. This approach prevents scorching or over-sublimation of the material.

4. The Importance of Time

Remember, it’s not just about the temperature itself; the time the material spends under the heat press also matters. Longer exposure times at lower and shorter times at higher temperatures can yield great results. Finding the right balance is critical.

5. Mind the Material

Different materials require different temperature settings. For instance, fabric, ceramics, and metals have varying heat absorption and retention properties. Consider the specific material you’re working with to tailor your temperature settings accordingly.

6. Testing, Testing, 1-2-3

Never underestimate the power of Testing. Keep a record of your temperature settings and each print’s outcome. This record will be a valuable reference for future projects, allowing you to fine-tune your approach over time.

7. Beware of Dye Migration

Dye migration occurs when the dye molecules on the sublimated material revert to a gaseous state due to excessive heat, leading to colour bleeding or ghosting. To prevent this, ensure your heat press temperature is within the recommended range and avoid using extreme pressure.

Remember, achieving the perfect sublimation print involves a combination of temperature, time, and technique. Keep these pro tips in mind as you experiment and hone your skills. By mastering the art of heat press temperature, you’ll unlock a world of vibrant and long-lasting sublimation creations.

Sublimation Heat Press Settings Comparison Table

| Product | Temperature (°C) | Time | Pressure |

|---|---|---|---|

| Polyester Fabric | 200 to 205 | 35 to 40 seconds | Medium |

| Ceramic Mugs | 190 to 200 | 20 seconds | Medium to Firm |

| Ceramic Plates | 190 to 200 | 60 seconds | Medium |

| Metal Tumblers | 160 to 170 | 25 seconds | Medium to Firm |

| Umbrellas | 190 to 195 | 45 seconds | Medium |

| Neoprene Items | 200 to 205 | 40 seconds | Medium |

| Metal Items | 190 to 200 | 60 seconds | Medium |

| Face Masks | 240 to 245 | 45 seconds | Medium |

| Over Heat Transfer Vinyl | 175 to 180 | 30 to 35 seconds | Medium |

| Canvas | 185 to 190 | 40 seconds | Medium |

| Polyester Cushions | 200-205 | 35 to 40 seconds | Medium |

Tips:

- – Pre-press fabric for 5-10 seconds before printing.

- – Let mugs cool on the press for 1 minute after pressing.

- – Remove plastic coating from ceramic plates before pressing.

- – Use thermal tape on curved surfaces of metal tumblers.

- – Avoid contact with plastic parts when sublimating umbrellas.

- – Thoroughly clean the press before sublimating neoprene items.

- – Use an absorbent sheet in the press for metal items.

- – Remove the inner cotton layer from face masks if present.

- – Apply vinyl first and let it cool before sublimating over heat transfer vinyl.

- – Pre-press canvas before sublimating.

- – Pre-press polyester cushions like a shirt.

How Hot Should My Heat Press Be for Sublimation?

Successful sublimation depends on having the right temperature for your heat press. The recommended temperature is usually between 380°F (193°C) and 400°F (204°C).

Following the specific guidelines provided by your sublimation paper and ink manufacturers is crucial. With these instructions, you can ensure that your materials receive vibrant and long-lasting prints through optimal heat settings.

What Temperature Do You Sublimate 100% Polyester?

Sublimating 100% polyester requires specific temperature settings to achieve optimal results. It is advisable to set the heat press temperature between 380°F (193°C) and 400°F (204°C) for sublimating 100% polyester fabric.

This temperature range allows the sublimation inks to vaporize and bond effectively with the polyester fibers, resulting in vibrant and long-lasting prints.

Temperature chart for a sublimation heat press machine:

| Material | Temperature (°F) | Temperature (°C) |

|---|---|---|

| Polyester | 380-400 | 193-204 |

| Ceramic | 400-420 | 204-216 |

| Aluminum | 400-420 | 204-216 |

| Glass | 380-400 | 193-204 |

| Wood | 380-400 | 193-204 |

| Cotton | 380-400 | 193-204 |

| Nylon | 380-400 | 193-204 |

| Spandex | 380-400 | 193-204 |

| Leather | 380-400 | 193-204 |

| Linen | 380-400 | 193-204 |

What Heat Settings and Time for Sublimation?

In addition to temperature, heat press settings and time play a crucial role in sublimation printing. Here are some general guidelines to follow:

- Pressure: Apply medium to high pressure on the heat press machine to ensure proper ink transfer onto the substrate.

- Time: The recommended time for sublimation can vary depending on the substrate and equipment. As a starting point, a pressing time of 45-60 seconds is commonly used for sublimation printing.

- Note: It’s essential to experiment and perform test prints to determine the best settings for your specific equipment and materials.

What Setting Do You Heat Press a Shirt for Sublimation?

The ideal temperature for sublimating on 100% polyester is between 380-400 degrees Fahrenheit. For 65% polyester, the temperature can be slightly lower, around 375-385 degrees Fahrenheit. Sublimation is not possible for cotton because it is a natural fiber that does not absorb dye.

Table of sublimation temperatures for different fabric compositions:

| Fabric Composition | Temperature (°F) |

|---|---|

| 100% Polyester | 380-400 |

| 65% Polyester, 35% Cotton | 375-385 |

| 100% Cotton | Not possible |

| Acrylic | 370-400 |

| Nylon | 375-390 |

| Spandex | 370-385 |

What Heat Press Setting for 100% Polyester T-Shirts?

Sublimating 100% polyester t-shirts requires similar heat press settings as mentioned earlier. Set the temperature between 380°F (193°C) and 400°F (204°C), apply medium to high pressure, and use a pressing time of 45-60 seconds.

Remember to refer to the specific recommendations provided by your sublimation ink and paper manufacturers for optimal results.

Can you sublimate at 325 degrees?

No, you cannot sublimate at 325 degrees Fahrenheit. The ideal temperature for sublimation is between 380-400 degrees Fahrenheit. At 325 degrees Fahrenheit, the dye cannot vaporize and transfer to the substrate.

If you try to sublimate at 325 degrees Fahrenheit, you will likely have a blurry or faded image. In some cases, the image may not transfer at all.

To achieve the best results, it is crucial to use the correct temperature and pressure when sublimating. Before starting your project, it’s a good idea to test your settings on a scrap piece of material if you’re still unsure about which ones to use.

Mug Press Temperature and Time

Using a mug press at 385-400°F (196-204°C) for 180-240 seconds (3-4 minutes) is the recommended method for standard ceramic mugs. Make sure to follow the instructions on your mug and press for the best results. Here are instructions for the Mug and Press.

Mug:

- Material: Ceramic

- Coating: Sublimation-coated

- Press Temperature: 385-400°F (196-204°C)

- Press Time: 180-240 seconds (3-4 minutes)

- Care: Hand wash only, avoid abrasive cleaners

Press:

- Preheat: Preheat the press to the desired temperature.

- Place Mug: Securely place the mug with the sublimation paper facing the heating element.

- Press: Close the press and set the timer for the recommended time.

- Cool Down: Allow the mug to cool completely before handling.

- Maintenance: Clean the press regularly to prevent residue buildup.

Common Queries:

Always refer to the guidelines provided by your sublimation ink and paper manufacturers for the best results.