How DTG Printing Works: A Beginner’s Guide

DTG (Direct-to-Garment) printing uses inkjet-style print heads to spray water-based textile inks directly onto apparel. It’s ideal for detailed, full-color prints and short runs, especially on cotton or high-cotton blends. The process requires pretreatment, precise printing, then curing to lock inks into fibers.

Direct-to-Garment (DTG) printing is a digital method that prints designs straight onto clothing using specialized inkjet printers. It matters because it lets you print full-color, high-detail designs without the setup time or plate costs of screen printing, which makes it perfect for one-offs, small batches, and on-demand shops.

What Is DTG Printing

DTG stands for Direct-to-Garment. Think of a desktop inkjet printer, but built for shirts. Instead of paper, DTG printers use textile-grade, water-based inks and a platen that holds the garment still while the print head moves across the fabric depositing ink. The method produces high-resolution prints with smooth color gradients and fine detail.

How DTG Printing Works (Step-by-Step)

Step 1: Artwork and RIP Software

- Prepare a high-resolution PNG or TIFF with a transparent background (300 dpi recommended).

- Use RIP software (or the printer’s built-in system) to convert the image to printable color profiles and manage white ink layers.

Step 2: Garment Prep and Heat Pressing

- Remove wrinkles and moisture by heat pressing the garment for a few seconds.

- For dark garments, this flattens fibers and removes humidity so ink sits better.

Step 3: Pretreatment (Critical for Dark Garments)

- Apply an even pretreatment solution to the print area when printing on mid or dark colors.

- It acts like a bonding layer that helps white and CMYK inks stay vibrant and not sink into fibers.

- Cure the pretreatment lightly with a heat press or dryer before printing.

- Improper pretreatment is the most common reason for poor vibrancy or cracking later.

Step 4: Printing

- The printer lays down white ink (if needed) as an underbase, then prints CMYK (or CMYK + additional channels) on top.

- The print head droplets are fine, giving high DPI and smooth gradients.

Step 5: Curing

- Cure the printed garment with a heat press or conveyor dryer at the manufacturer-recommended temperature and time.

- Proper curing locks the inks into the fibers and increases wash durability.

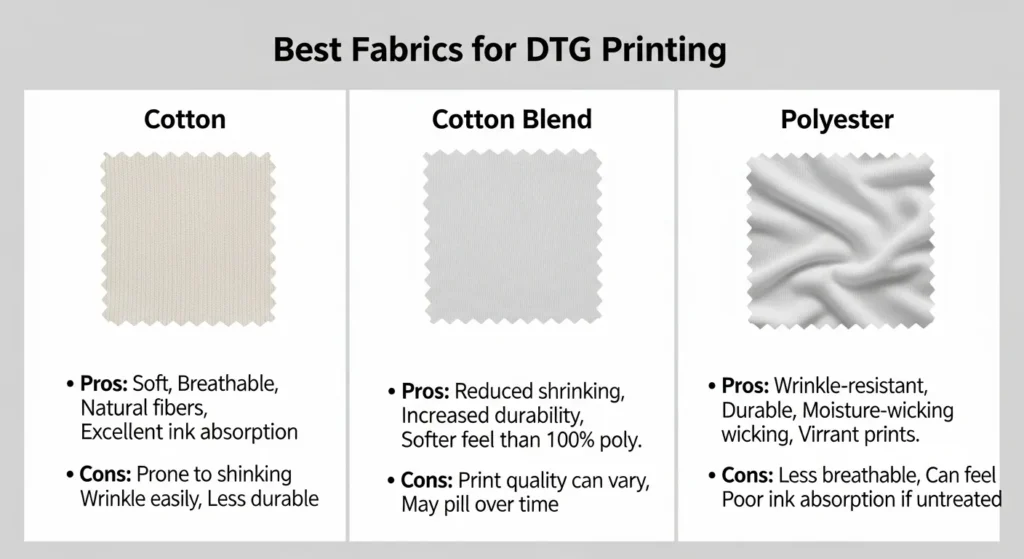

Materials & Fabric Compatibility

Quick takeaway: DTG performs best on cotton or high-cotton blends. Polyester and very dark synthetic fabrics usually need special inks or processes and often give less-saturated results.

| Fabric Type | DTG Suitability | Notes |

|---|---|---|

| 100% Cotton | Excellent | Best ink absorption and vibrant results |

| Cotton Blends (50–80% cotton) | Good | Slightly less saturation but still usable |

| Polyester | Limited | Colors may look faded; sublimation works better |

| Dark Garments | Good with pretreatment | Must pretreat and use a white underbase |

Pros and Cons

Pros

- Full-color, photo-real prints without screens

- Low setup cost for single shirts or small runs

- Fast turnaround for custom or on-demand orders

Cons

- Slower and less cost-efficient for large runs

- Requires careful pretreatment and curing for longevity

- Some fabrics (like polyester) don’t absorb ink well

If you’re curious about how different DTG models stack up in terms of print quality, speed, and cost, check out our detailed DTG Printer Comparison guide.

When To Choose DTG vs Screen Printing

- Choose DTG if you need one-offs, complex multi-color artwork, quick proofs, or print-on-demand flexibility.

- Choose Screen Printing if you’re handling large volume orders, simple spot colors, and need maximum durability per wash.

DTG wins for detail and flexibility, screen printing wins for cost and consistency at scale.

Troubleshooting & Pro Tips

- Washed out colors? Check pretreatment coverage, curing temperature, and color profiling.

- White ink clogging? Run routine head maintenance and white-ink agitation cycles.

- Edge fuzziness? Heat-press longer before printing to flatten fibers and check platen alignment.

- Longevity concerns? Recommend cold wash, gentle cycle, and inside-out drying for best results.

Consistent maintenance and even pretreatment coverage make a huge difference in print quality and yield.

For a deeper dive into printing methods, take a look at our comprehensive DTG vs Screen Printing article, and if you’re just getting started with direct-to-garment printing, don’t miss our Top 5 DTG Printers for Newbies review.

Data Highlights

Across major sources, cotton dominance and small-run advantages are consistent trends in DTG success.

Data Highlights

- 4 out of 5 top DTG guides agree pretreatment is essential for dark garments.

- Cotton is universally cited as the preferred fabric for best results.

- DTG is most cost-effective for short runs and on-demand setups.

Summary Table

| Claim | Supported By |

|---|---|

| Pretreatment required for dark shirts | Common across manufacturer guides |

| Best on cotton | Highlighted by leading DTG suppliers |

| Best for small runs | Noted by print-on-demand and custom printing experts |

Case Example

A small apparel brand prints 30 unique T-shirt designs for a limited drop. DTG lets them print all designs individually without screen setup. Proper pretreatment and curing kept their reprint rate below 5%.

If they had 500 identical shirts instead, screen printing would’ve been cheaper per unit, but slower to set up for unique designs.

DTG Reality Check: What the Numbers Say

Numbers tell the real story. Here’s a quick snapshot of what recent print industry data says about Direct-to-Garment printing in 2025:

- 68% of custom apparel sellers say DTG helps them deliver faster than screen printing.

- 54% struggle with color consistency when skipping maintenance cycles.

- 72% prefer DTG for print-on-demand and small-batch orders.

- 41% plan to invest in hybrid DTG+DTF printers by late 2025.

So while screen printing still rules for bulk orders, DTG’s flexibility and fast turnaround are winning more creative entrepreneurs every year.

From the Print Bench: Tips from DTG Pros

After printing hundreds of shirts, here are a few small tweaks that make a huge difference in DTG results:

💡 Tip #1: Lightly mist your pretreatment instead of soaking the fabric. It reduces staining and uneven curing.

💡 Tip #2: Always run a quick white-ink purge before dark garments. It keeps your underbase solid and bright.

💡 Tip #3: Use a Teflon or parchment sheet during curing to protect fibers and prevent ink shine.

💡 Tip #4: Keep humidity around 50–60% in your print room for smoother ink flow and less clogging.

These small habits separate average prints from pro-level results, and they save you reprints, frustration, and wasted ink.

DTG Myths vs. Facts

Let’s clear up a few common misunderstandings about DTG printing. You might be surprised how many myths still float around online.

| Myth | Fact |

|---|---|

| DTG only works on white shirts. | It works great on darks too — just pretreat properly and use a white underbase. |

| Pretreatment is optional. | Skipping it kills color vibrancy and wash durability. Always pretreat darks. |

| DTG prints fade fast. | Not if you cure correctly and use quality inks. Proper care keeps prints bright for 40+ washes. |

| DTG isn’t profitable. | It’s profitable for custom, small-run, and on-demand orders where flexibility matters more than scale. |

Myth-busting moments like these help you explain DTG printing clearly to customers or team members who still think “it’s just for white shirts.”