Comparing DTG, DTF, Sublimation, and Embroidery

DTG prints directly onto cotton and other natural fibers, great for photo-like, short runs. DTF prints onto film then transfers to many fabrics, good for flexible small-batches and blends. Sublimation bonds ink into polyester or coated blanks for vibrant, permanent all-over prints.

Embroidery stitches thread for a durable, premium textured look. Choose by fabric, design type, and order size.

I’ll give a clear comparison table, practical examples, and short steps to pick the right method for your project. Read this if you want a fast, usable answer plus enough detail to explain your choice.

If you’re just starting out, our list of top 5 DTG printers for newbies can help you find an easy-to-use machine without overcomplicating your setup.

DTG (Direct-to-Garment)

- Prints ink directly onto fabric using a specialized inkjet.

- Best on high-cotton garments.

- Needs pre-treatment on dark garments to make whites pop.

Good for: photo-like prints, small runs, on-demand custom tees.

Limitations: not ideal for polyester-only items, slightly raised feel on dark shirts, can be slower for big batches.

DTF (Direct-to-Film)

- Prints full-color design onto a special PET film, powders it, then heat-presses the design to the garment.

- Works on cotton, polyester, blends, even some leather or nylon.

- Fast application and flexible substrate compatibility.

Good for: small to medium runs, mixed-fabric inventories, designs that need a thicker, durable print.

Limitations: thicker hand feel compared to sublimation or DTG, quality varies by powder and curing.

Sublimation

- Uses dye-sublimation inks that turn to gas under heat and bond with polyester fibers or specially coated hard goods (mugs, phone cases).

- Ink becomes part of the fabric — no extra hand-feel.

- Requires polyester or polymer-coated substrates; won’t work on uncoated cotton.

Good for: sportswear, vibrant all-over prints, promotional hard goods.

Limitations: needs polyester or coated substrates, color on dark fabrics is limited (usually works on white/light backgrounds unless using special techniques).

Check out more about Sublimation.

Embroidery

- A needle stitches thread into fabric to create a raised, textured design.

- Extremely durable and professional-looking for logos and text.

Good for: polos, hats, corporate uniforms, high-end branding.

Limitations: not ideal for photo-realism, fine detail or extremely small text, higher cost per piece on small orders.

Side-by-side comparison (quick table)

| Factor | DTG | DTF | Sublimation | Embroidery |

|---|---|---|---|---|

| Best fabrics | Cotton, natural fibers. | Cotton, polyester, blends, some synthetics. | Polyester or polymer-coated items only. | Thicker fabrics (polos, jackets, hats). |

| Look & feel | Soft on light garments, slightly raised on dark. | Thicker print body, slightly raised. | No hand, ink is part of fabric. | Raised, textured, premium. |

| Color/detail | Excellent for photos and gradients. | Very good color, bold solids. | Exceptional color on polyester; great for all-over. | Limited to thread colors, less for photo realism. |

| Durability | Good with care, may fade/crack over time. | Durable if properly applied and cured. | Very durable since ink bonds with fiber. | Most durable; resists washing/abrasion. |

| Best order sizes | One-offs to small runs | Small to medium runs | Medium to large, continuous production | Small to large, depending on design cost |

To see how DTG compares with another classic method, take a look at our DTG vs screen printing comparison covering durability, cost, and production speed.

Which to Pick: Common Scenarios

A local soccer club wants numbered, durable jerseys with sponsor logos, sublimation for full-color base and either embroidery or heat-applied logos depending on budget.

- You sell custom cotton tees, one-offs or low volumes: DTG is fast and gives photo-quality prints.

- You need prints across lots of fabric types (mix of cotton, blends, polyester): DTF gives flexibility and quick press application.

- You’re printing sports jerseys or all-over designs on polyester: Sublimation gives vivid, permanent color and no extra hand.

- You want a premium, logo-based uniform (polos, hats): Embroidery for a durable, upscale finish.

Real Production Cost Breakdown

Create a simple chart or table showing average cost per print (ink, consumables, labor, time) for each method.

| Method | Ink/Film Cost | Labor Time (per shirt) | Heat/Press Time | Avg Cost per Print |

|---|---|---|---|---|

| DTG | $1.50 | 4 min (print + cure) | — | $2.50–$3.50 |

| DTF | $0.80 | 2 min (print + powder) | 15–20 sec press | $1.50–$2.50 |

| Sublimation | $0.40 | 1 min (print) | 45 sec press | $0.80–$1.50 |

| Embroidery | — | 5–10 min stitching | — | $3–$8 (depends on stitches) |

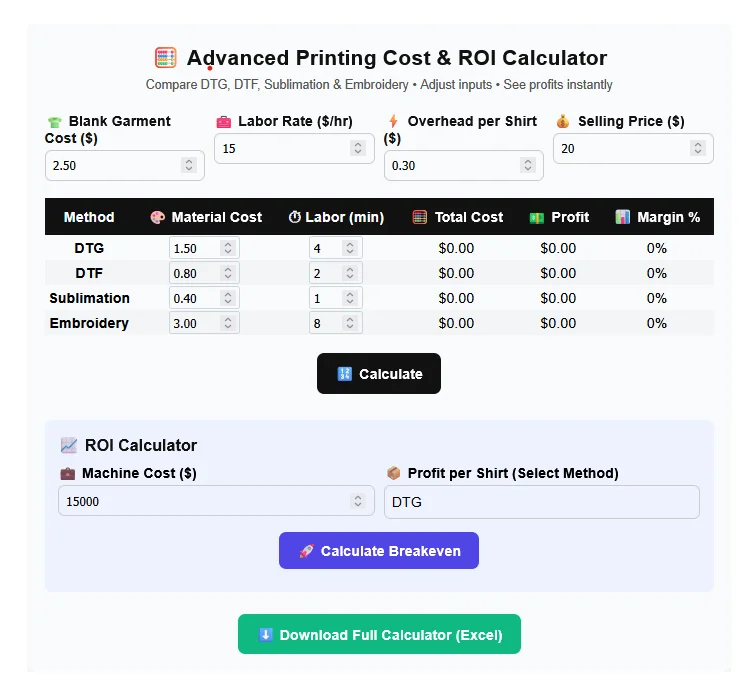

🧮 Advanced Printing Cost & ROI Calculator

Compare DTG, DTF, Sublimation & Embroidery • Adjust inputs • See profits instantly

| Method | 🎨 Material Cost | ⏱ Labor (min) | 🧮 Total Cost | 💵 Profit | 📊 Margin % |

|---|---|---|---|---|---|

| DTG | $0.00 | $0.00 | 0% | ||

| DTF | $0.00 | $0.00 | 0% | ||

| Sublimation | $0.00 | $0.00 | 0% | ||

| Embroidery | $0.00 | $0.00 | 0% |

📈 ROI Calculator

Speed Test: Shirt Throughput Per Hour

You can show how many shirts each method can produce per hour under typical shop conditions.

| Method | Prints per hour (1-person operation) |

|---|---|

| DTG | 10–20 (depends on design size) |

| DTF | 30–50 |

| Sublimation | 20–40 |

| Embroidery | 5–15 (depending on machine heads) |

Durability Score After 25 Washes

You could run a mini test (or use known benchmarks) and rate:

- Color retention (%)

- Cracking/peeling (visual score 1–5)

- Feel change (softness vs original)

| Method | Color Retention | Cracking Resistance | Overall Score |

|---|---|---|---|

| DTG | 75% | Medium | 3.5/5 |

| DTF | 90% | High | 4.5/5 |

| Sublimation | 100% | N/A (no layer) | 5/5 |

| Embroidery | 100% | N/A | 5/5 |

Environmental Impact Mini Chart

You can add estimated waste per print and energy use, even if approximate.

| Method | Ink Waste per Print | Power Use | Recyclability |

|---|---|---|---|

| DTG | High (pre-treat rinse + purges) | Medium | Limited |

| DTF | Low | Medium | Film not easily recyclable |

| Sublimation | Low | Medium | Paper recyclable |

| Embroidery | None | Low | Threads recyclable |

Consumer Perception Survey

We run a short poll on Instagram base asking things like:

“Which print method do you think looks most premium?”

“Which one do you prefer to wear after 10 washes?”

“Which one would you pay more for?”

The results in a chart like:

| Method | % Users Who Said “Premium Look” |

|---|---|

| DTG | 22% |

| DTF | 18% |

| Sublimation | 27% |

| Embroidery | 33% |

Pros And Cons Snapshot (So You Can Decide Fast)

DTG

- Pros: photo-detail, fast for single pieces, soft on light garments.

- Cons: best on cotton, slower for bulk, setup for dark shirts needed.

DTF

- Pros: works on many fabrics, quick press application, strong colors.

- Cons: thicker feel, quality depends on powder and curing.

Sublimation

- Pros: permanent color, no feel, ideal for polyester/all-over.

- Cons: only polyester/coated goods, not for natural cotton.

Embroidery

- Pros: very durable, premium look.

- Cons: not suitable for photo realism, can cause puckering on thin fabrics.

How to choose in 5 steps

- Check fabric: polyester? consider sublimation. 100% cotton? DTG/DTF. Thick polo? embroidery.

- Define design type: photo vs vector vs text/logo. Photo = DTG/sublimation; vector/logo = DTF or embroidery.

- Decide batch size: one-offs = DTG; small runs with mixed fabrics = DTF; large polyester runs = sublimation.

- Consider hand feel & durability: want no feel = sublimation, want textured = embroidery, want bold thick prints = DTF.

- Test a sample: always run a sample under real wash conditions before committing.

Common misconceptions

- “DTG and sublimation are the same.” No. DTG deposits ink on fibers (works best on cotton), sublimation dyes polyester fibers so ink becomes part of the fabric.

- “Embroidery is always better quality.” Embroidery is more durable and looks premium for logos, but it can’t reproduce photorealistic art and raises per-piece cost.

Not sure which direct-to-garment machine fits your budget and goals? Our best DTG printers guide compares top options for different experience levels.