Water-Based Inks: The Eco-Friendly Choice for Screen Printing

I didn’t fully appreciate how different water-based inks felt until I pulled my first shirt off the press and realized it actually felt like fabric, not a layer sitting on top.

That moment made me curious about what was happening beneath the surface, and why some printers swear by water-based inks while others avoid them completely.

Let’s break it all down, clearly and honestly.

What Water-Based Screen Printing Inks Are

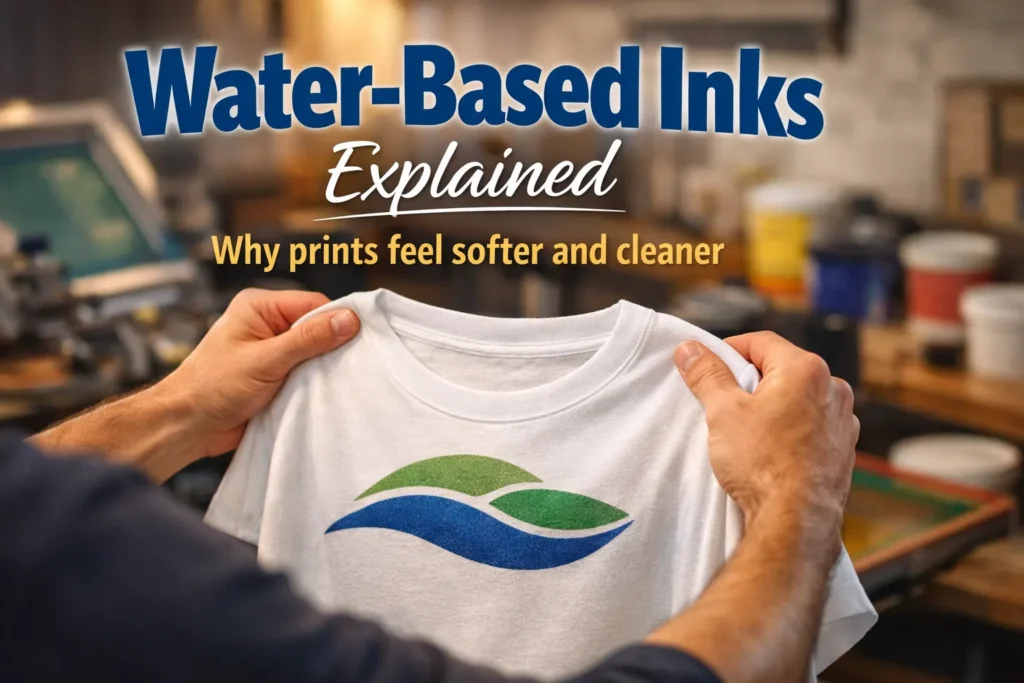

Water-based screen printing inks use water as the primary carrier, which changes how the ink behaves from the moment it hits the screen.

Instead of sitting on top of the garment, the ink absorbs into the fibers, similar to how dye behaves in sublimation, which we also explain when breaking down the fundamentals of what sublimation printing is.

Key characteristics

- Pigment bonds inside the fabric

- Print feels soft and breathable

- No plastic layer on the surface

- Ink reacts to air, heat, and humidity

Because the ink penetrates fibers, mistakes are harder to hide. There’s no thick layer to mask issues.

Why Water-Based Inks Are Considered Eco-Friendly

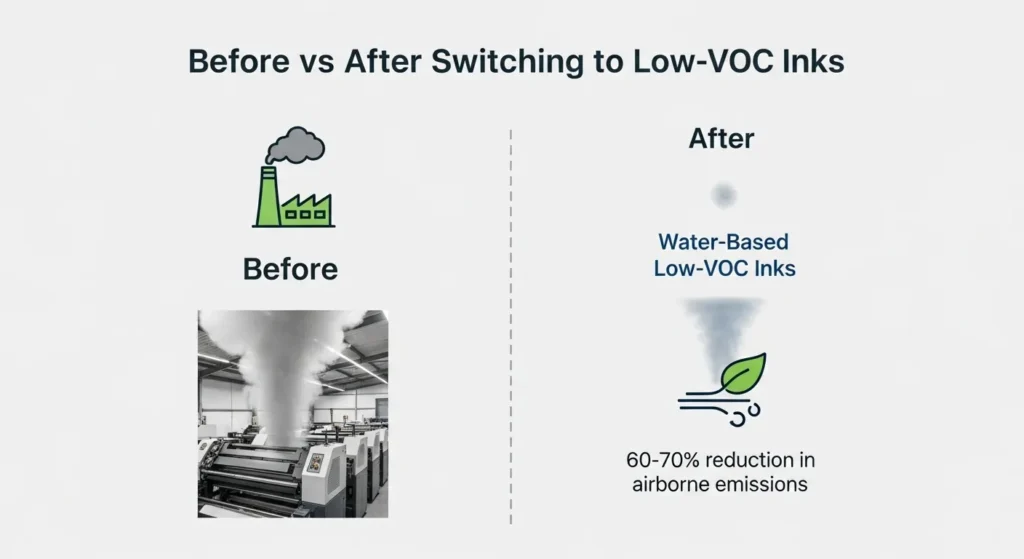

“Eco-friendly” only matters if it changes real-world impact. Water-based inks reduce environmental and health risks in three measurable ways:

Environmental factors

- Low or zero VOCs compared to plastisol inks

- Water-based cleanup, no aggressive solvents

- Reduced chemical disposal from press and screen wash

According to industry safety data, low-VOC inks can reduce airborne emissions by up to 60–70% in small print environments.

This aligns with broader sustainability shifts discussed in our breakdown of embracing sustainability in modern printing.

NOTE: Eco-friendly does not mean impact-free. Water use, wastewater handling, and curing energy still matter.

For more on eco-friendly screen printing inks, visit Subli Genius Print.

Water-Based Inks vs. Other Inks

| Ink Type | VOC Emissions | Health & Safety | Environmental Impact |

|---|---|---|---|

| Water-Based Inks | Low | Safer | More Eco-Friendly |

| Plastisol Inks | High | Less Safe | Less Eco-Friendly |

| Solvent-Based Inks | High | Less Safe | Less Eco-Friendly |

Use Cases and Limitations

Water-based inks are ideal for:

- Soft-hand prints on light-colored fabrics.

- Eco-friendly product lines.

However, they may not be the best choice for:

- High-opacity needs on dark fabrics without underbase.

- Quick production runs due to longer drying times.

For a comparison with other eco-friendly options, check out our guides on Soy-Based Inks and UV-Curable Inks.

Advantages and Disadvantages of Water-Based Inks

This is where most guides fall apart by overselling the upside.

Advantages

- Extremely soft hand feel

- Breathable, fashion-grade prints

- Ideal for premium and retail garments

- Better wearer comfort in warm climates

Disadvantages

- Ink can dry in the screen

- Sensitive to temperature and humidity

- Lower opacity on dark fabrics

- Requires tighter process control

We take the same balanced approach here that we use when explaining the real-world benefits of sublimation printing, pros only matter when cons are understood.

Water-Based Ink vs Plastisol Ink

Water-based inks reward precision. Plastisol rewards speed and forgiveness. This comparison decides whether a printer switches or stays put.

| Feature | Water-Based Ink | Plastisol Ink |

|---|---|---|

| Print feel | Soft, breathable | Thick, rubbery |

| Fabric bonding | Absorbs into fibers | Sits on top |

| VOC emissions | Low to none | Higher |

| Ease of use | Moderate learning curve | Beginner-friendly |

| Dark garments | Challenging | Excellent |

| Cleanup | Water | Solvents |

For a broader process comparison, this mirrors the same decision logic explained in sublimation vs screen printing.

Cost Comparison: Water-Based Ink vs Plastisol Ink

Typical Price Breakdown (Small to Mid-Size Print Shops)

| Cost Factor | Water-Based Ink | Plastisol Ink |

|---|---|---|

| Ink price per gallon | $45–$70 | $55–$85 |

| Ink usage per print | Higher absorption | Lower, sits on top |

| Curing energy cost | Moderate to high | Moderate |

| Cleanup supplies | Low (water-based) | Higher (solvents, chemicals) |

| Screen maintenance cost | Moderate | Lower |

| Waste ink loss | Higher if ink dries | Lower |

| Average cost per print | $0.35–$0.55 | $0.25–$0.45 |

What These Numbers Really Mean

➡️ Water-based inks can cost slightly more per print if your workflow isn’t optimized, mainly due to ink absorption and drying losses.

➡️ Plastisol inks are more forgiving, which often keeps per-print costs lower in high-volume runs.

Best Fabrics and Garments for Water-Based Screen Printing

Fabric choice is the silent success factor most printers miss.

Best-performing fabrics

- 100% cotton

- Ringspun cotton

- Light-colored natural fibers

Fabrics that cause issues

- Polyester and high-poly blends

- Dark garments without special handling

- Coated or treated fabrics

This fabric dependency mirrors what we see when selecting materials in guides like best fabrics for sublimation.

How Water-Based Screen Printing Inks Cure

Curing is the #1 failure point for water-based prints.

Proper curing requires

- Complete moisture evaporation

- Sufficient heat exposure

- Even airflow

Most water-based inks cure between 300–330°F, depending on fabric and ink load. Under-curing leads to wash-out, over-curing risks fabric damage.

We address similar heat-control mistakes in our sublimation heat guide, and the same discipline applies here.

Using Water-Based Inks

Printing Techniques and Tips

- Pre-treatment: Use a fabric pre-treatment to enhance ink adhesion and color vibrancy.

- Curing Process: Ensure a complete cure to prevent washout, typically requiring a longer drying time.

Troubleshooting Common Issues

- Ink Drying in the Screen: Keep the screen flooded between prints.

- Achieving Vibrant Colors on Dark Fabrics: Use a white underbase or choose inks with high-opacity formulas.

The Environmental Impact of Water-Based Inks

Sustainability Features

- Reduced Carbon Footprint: Lower energy requirements for drying and curing.

- Enhanced Worker Safety: Minimized exposure to toxic chemicals.

Case Studies and Certifications

Look for suppliers and brands that offer transparent information on their sustainability practices and product certifications.

How to Print With Water-Based Inks Successfully

Most frustration with water-based inks doesn’t come from the ink itself, it comes from setup.

If your setup is off, the ink will expose every weakness in your process. This is similar to what happens when steps are skipped in the sublimation process, precision matters more than force.

Setup factors that matter most

- Mesh count: Higher mesh counts (156–230) reduce ink buildup

- Stencil quality: Clean, even emulsion prevents drying pockets

- Flooding technique: Keeps ink usable between pulls

Best-practice printing workflow

- Flood the screen between every print

- Maintain a consistent print stroke

- Avoid long pauses during runs

- Work in smaller batches when learning

NOTE: If ink starts drying mid-run, stopping to reset is faster than pushing through and ruining shirts.

Common Water-Based Ink Problems and How to Fix Them

Almost every issue shows up in predictable ways. The fix is usually simpler than it feels in the moment.

For structured troubleshooting, this section follows the same logic used in our troubleshooting guide for printing issues.

Problem → Cause → Fix

| Problem | Likely Cause | Fix |

|---|---|---|

| Ink drying in screen | Dry air, slow printing | Increase flooding, reduce pauses |

| Dull prints | Wrong fabric or underbase | Switch fabric or adjust opacity |

| Wash-out after curing | Incomplete cure | Increase heat or dwell time |

| Cracking | Over-curing or poor bond | Reduce heat, check fabric |

Over-adjusting creates new problems. Change one variable at a time.

Additives and Modifiers Used With Water-Based Inks

Additives exist to solve specific problems, not to improve prints by default.

This mirrors how chemical adjustments are explained in broader printing ink technologies, chemistry only helps when it’s intentional.

Common additive purposes

- Slow drying during long runs

- Improve opacity on darker garments

- Increase softness or flexibility

When additives help

- Dry shop environments

- Large production runs

- Specialty fabric challenges

When additives hurt

- Overuse causes curing issues

- Can reduce wash durability

- Adds inconsistency for beginners

If your prints work without additives, don’t add them “just because.”

Environmental Impact in Real Printing Environments

Sustainability isn’t just about ink choice, it’s about workflow.

Water-based inks reduce chemical exposure, but process decisions determine real impact. This forward-looking view aligns with ideas discussed in the future of print production.

Where impact is reduced

- Fewer chemical cleaners

- Lower VOC emissions

- Safer shared or home workspaces

Where impact still exists

- Water usage during cleanup

- Energy used for curing

- Wastewater handling

Stat to keep in mind:

Improving workflow efficiency can reduce waste by 20–30%, even without changing ink types.

Is Water-Based Screen Printing Right for You

This is the decision point. We approach this the same way we do in our buyers guide for printing methods, matching tools to goals instead of trends.

Water-based inks make sense if you:

- Want ultra-soft, breathable prints

- Print on cotton or natural fibers

- Value workspace safety and comfort

- Are willing to learn process control

You may want to wait if you:

- Print mostly dark garments

- Run high-volume production

- Need maximum opacity fast

- Prefer forgiving workflows

Final NOTE: The “best” ink is the one that fits your process today, not the one everyone online is hyping.

Frequently Asked Questions:

Can I use water-based inks on any fabric?

You can, but they work best on natural fibers like cotton. Polyester blends and dark garments usually need extra steps or different ink systems to get good results.

Do water-based inks last as long as plastisol prints?

Yes, when they’re cured properly. Most durability issues come from under-curing, not the ink itself.

Is water-based screen printing safe to do at home?

It’s generally safer than traditional inks because it produces fewer fumes and uses less harsh chemicals, but proper ventilation is still important.

Why does water-based ink dry in my screen so fast?

Water-based inks react to air and dry conditions. Low humidity, slow printing, or long pauses can cause the ink to dry inside the stencil.

Do I need special equipment to cure water-based inks?

You don’t need specialty equipment, but you do need reliable heat and airflow. A proper curing setup makes a huge difference in wash durability.

Is water-based printing good for beginners?

It can be, as long as you’re willing to learn process control. Beginners who rush or skip testing often struggle at first.

Can I print water-based ink on dark shirts?

It’s possible, but more challenging. Dark garments often require underbases or special techniques to maintain color vibrancy.

How do I know if my water-based print is fully cured?

The simplest way is a wash test. If the print fades, cracks, or feels sticky after washing, it wasn’t fully cured.

Additional Resources:

Embracing water-based inks is more than a printing choice it’s a commitment to a greener future.