5 Tools That Make Sublimation Easier and Cleaner

Sublimation printing involves heat, pressure, and precise alignment. To reduce errors and improve output quality, several tools can help streamline the process. This guide outlines five reliable tools that improve accuracy, safety, and cleanliness in sublimation workflows.

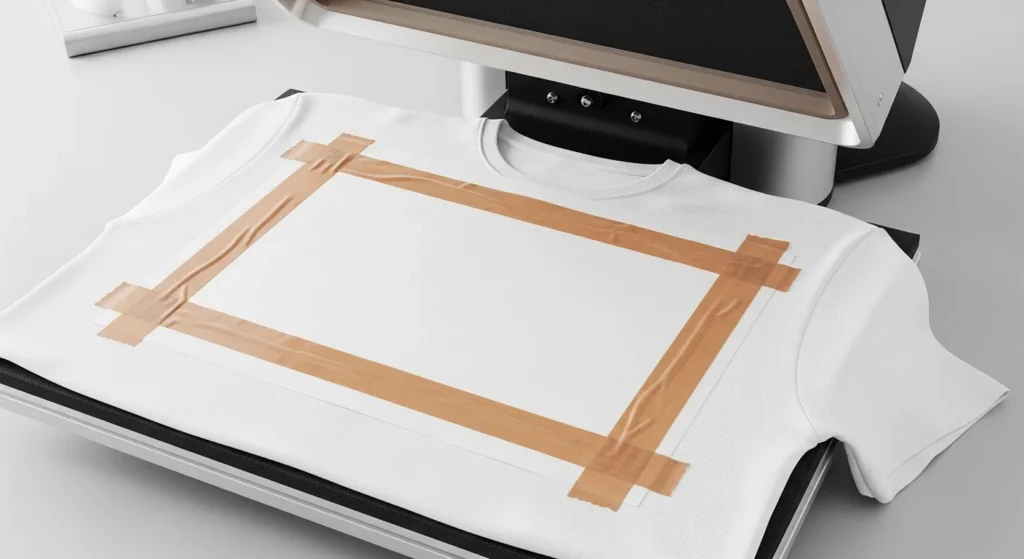

1. Heat-Resistant Tape

Purpose:

Secures transfer paper in place during pressing.

Why It Matters:

Sublimation transfers can shift during the press cycle, causing ghosting or double images. Heat-resistant tape holds designs steady without melting or leaving residue.

Common Questions:

- What temperature can it handle?

Most tapes are safe up to 400°F (204°C). - Can it be used on fabric and hard substrates?

Yes. Works for t-shirts, mugs, tumblers, metal, and more.

Tip: Use minimal tape to avoid blocking ink flow on soft substrates like polyester.

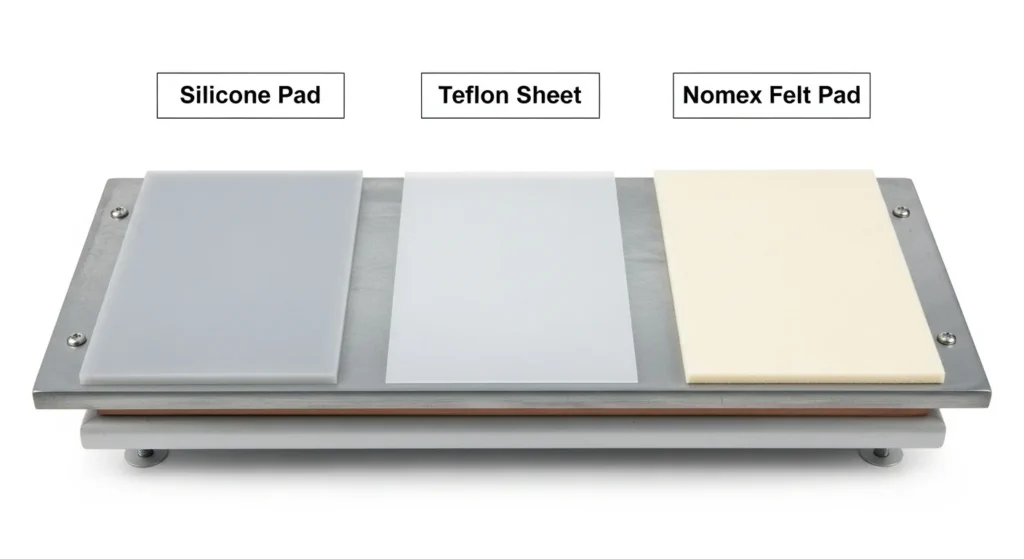

2. Heat Press Mat or Silicone Pad

Purpose:

Provides consistent pressure and protects surfaces.

Why It Matters:

A level, cushioned base helps even heat distribution. It also absorbs excess moisture and prevents surface burns or scorching.

Types Available:

| Type | Material | Best Use Case |

|---|---|---|

| Silicone Pads | Dense rubber | Flat items, high temp jobs |

| Teflon Sheets | PTFE-coated fabric | Between press plates and substrate |

| Nomex Pads | Heat-resistant felt | Delicate or curved substrates |

Tip:

Replace worn mats to maintain flatness and accurate pressure.

3. Lint Roller or Heat-Safe Lint Brush

Purpose:

Removes dust and loose fibers from fabrics before pressing.

Why It Matters:

Tiny fibers can trap moisture or cause unwanted blue specks on the final print. Pre-cleaning ensures a clean, vibrant result.

How to Use:

- Roll or brush fabric surface before placing transfer.

- Avoid brushing after heat is applied, as ink may smear.

Tip:

Use on all light-colored polyester blanks, especially shirts and pillowcases.

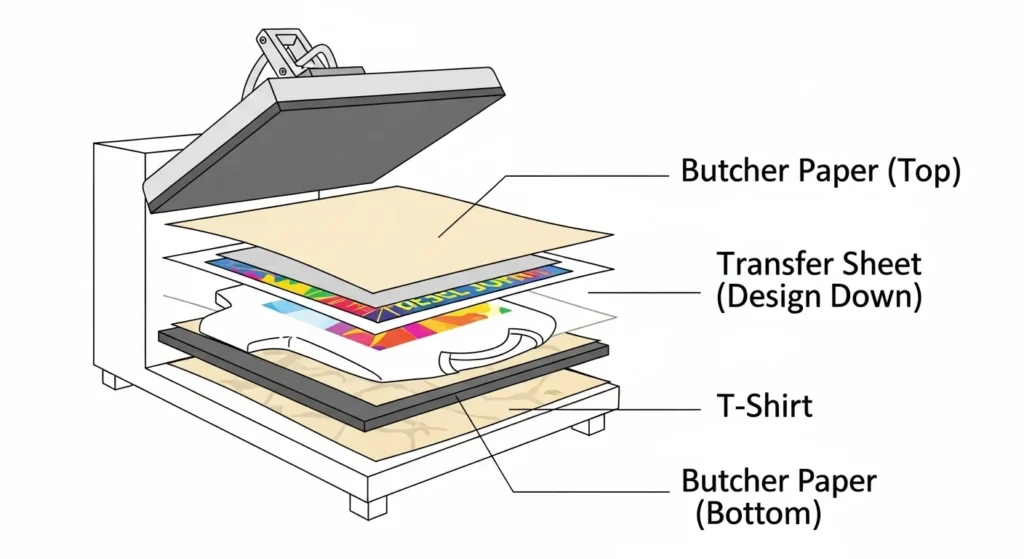

4. Butcher Paper or Parchment Sheets

Purpose:

Acts as a barrier between heat press surfaces and sublimation ink.

Why It Matters:

During sublimation, gas from the ink can bleed beyond the transfer sheet. This can stain the heat press or bleed onto other materials.

Comparison Table:

| Feature | Butcher Paper | Parchment Paper |

|---|---|---|

| Coating | None | Silicone-coated |

| Reusability | Single-use | Limited reuse |

| Heat Resistance | Up to 420°F | Up to 450°F |

| Ink Absorption | High | Medium |

Tip:

Avoid using wax paper, it melts under heat and can damage equipment.

5. Alignment Tools or Heat Tape Dispensers

Purpose:

Ensures accurate design placement.

Why It Matters:

Misaligned transfers can ruin a blank item, especially on curved or multi-surface objects.

Types of Alignment Tools:

- Rulers or Grid Mats: Help with centering designs on garments.

- Template Guides: Cut-outs or stencils for consistent placement.

- Tape Dispensers: Speed up application and reduce tape waste.

Tip:

Pre-mark the center of garments using a folding technique for faster positioning.

Check out 4 Common Heat Press Mistakes and How to Fix Them

Safety Precautions for Sublimation Printing

Working with heat presses, high temperatures, and sticky tools can be risky if you’re not careful. These safety tips keep you and your workspace protected while getting the best results.

1. Protect Your Hands and Skin

- Always wear heat-resistant gloves when handling hot items like mugs, tumblers, or freshly pressed fabric.

- Avoid touching the heat platen or press surfaces directly—temperatures can exceed 400°F (204°C).

2. Keep Your Workspace Clean

- Clear your area of loose papers, fabrics, or tools that could accidentally catch heat.

- Make sure cords aren’t tangled or in the way to prevent tripping near hot equipment.

3. Use Tools Correctly

- Only use heat-resistant tape, mats, or alignment guides for their intended purpose.

- Avoid improvising with regular tape or paper—they can melt and damage your press.

4. Ventilation Matters

- Sublimation inks release gas when heated. Use your heat press in a well-ventilated area or near a fan to avoid buildup.

5. Monitor Press Times and Temperatures

- Always follow manufacturer guidelines for time and temperature. Overheating can ruin blanks or cause burns.

- Never leave a heat press unattended while it’s on.

6. General Equipment Care

- Regularly inspect your heat press for frayed cords or worn parts.

- Clean surfaces only with recommended cloths or cleaning solutions to avoid accidents.

Tip: Making safety part of your workflow not only prevents injuries, it keeps your prints looking flawless without smudges or burns.

Practical Tips for Clean and Accurate Sublimation

- Always pre-press fabric to remove moisture before transfer.

- Replace protective paper after each press to avoid ghosting.

- Use clean gloves when handling sublimation blanks to avoid fingerprints or smudges.

- Regularly clean your heat press with a soft cloth to remove ink residue.

🚀 Elevate Your Printing Game

Professional printing resources for stunning results