Heat Press Temperature for Sublimation:

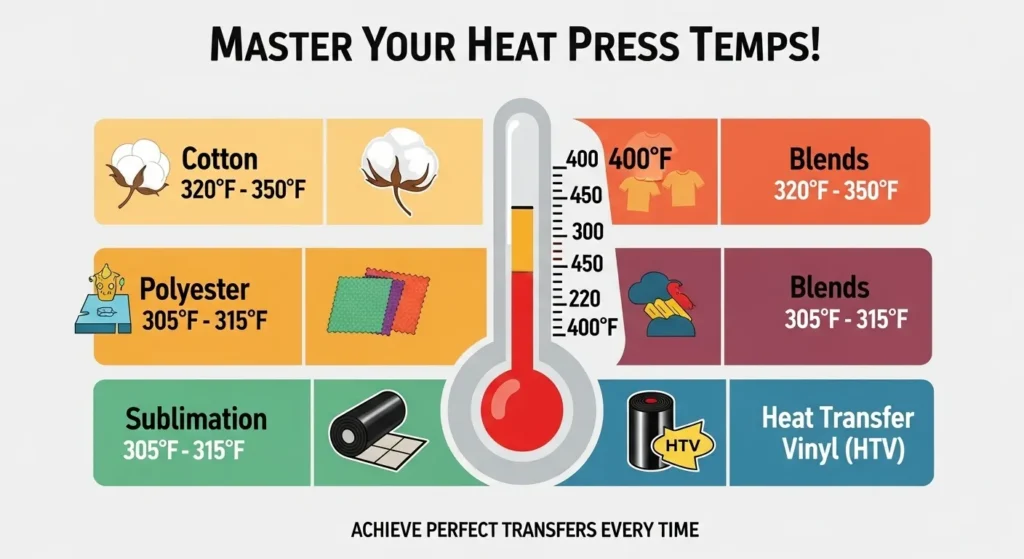

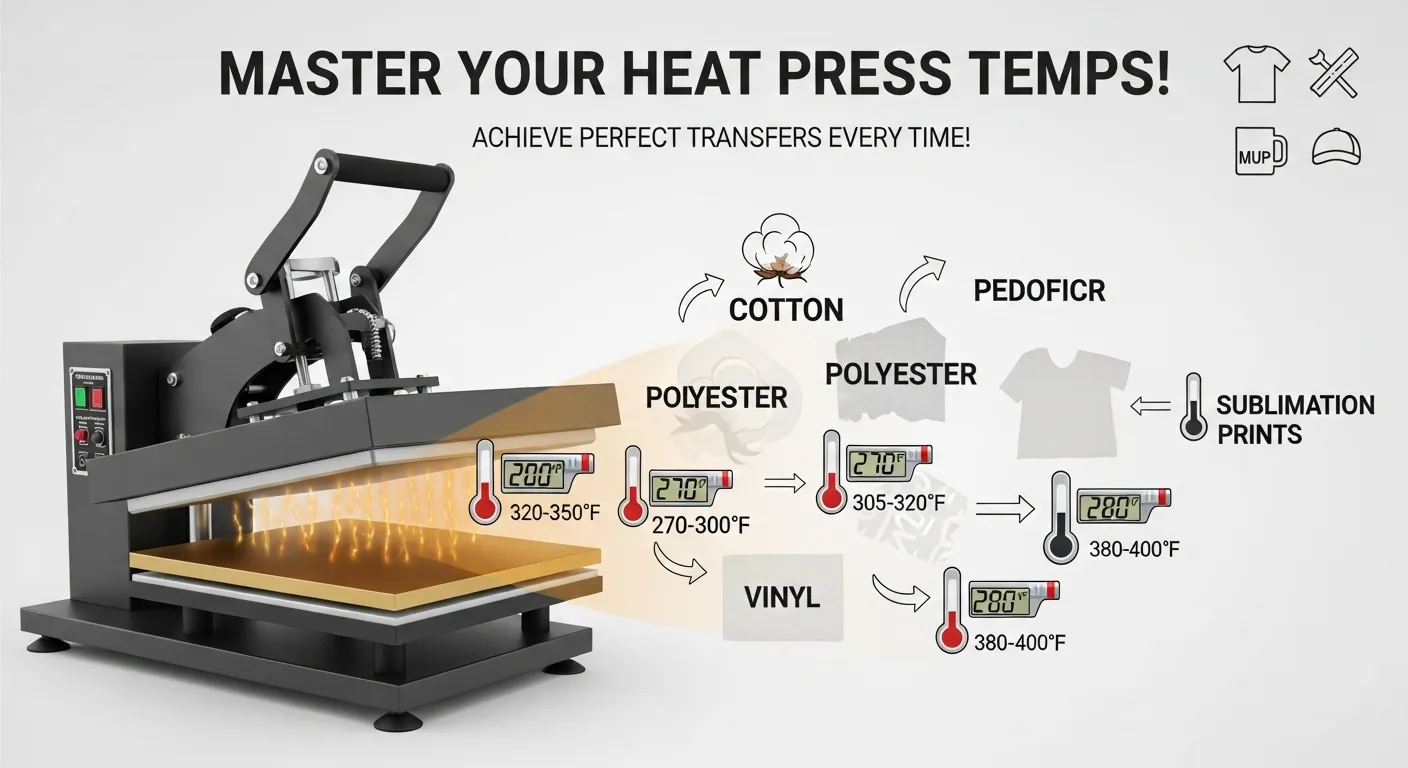

The best heat press temperature for sublimation is 380–400°F (193–204°C) with 40–60 seconds of medium pressure. Polyester needs the full range, while blends need lower heat, around 310–330°F.

Hard goods like mugs require 385–400°F for 180–240 seconds. Always test one blank first because press models vary by 10–20°F in real output.

Start by checking your sublimation printer settings, even a small mismatch can throw everything off.

If your colors still look off after pressing, a sublimation color chart can help pinpoint where the problem starts.

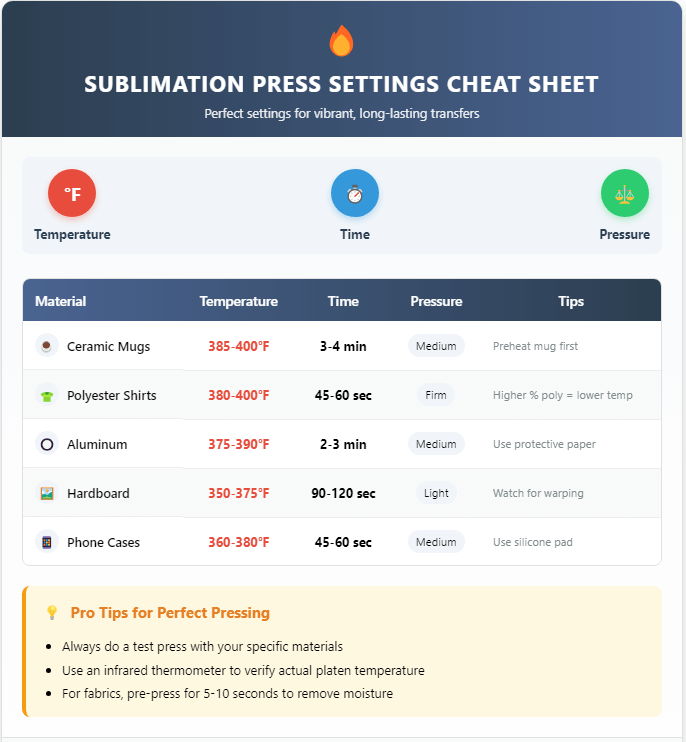

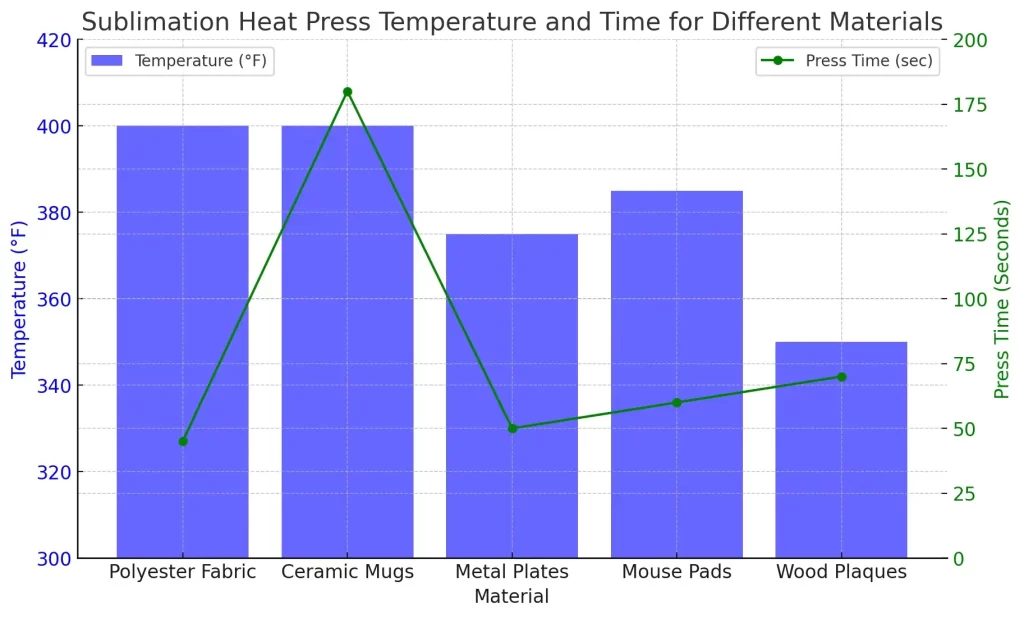

Complete Sublimation Temperature & Time Chart

| Material / Blank | Temperature (°F) | Temperature (°C) | Time | Pressure |

|---|---|---|---|---|

| 100% Polyester Fabric | 380–400°F | 193–204°C | 40–60 sec | Medium |

| 65/35 Poly-Cotton Blends | 375–385°F | 190–196°C | 25–40 sec | Medium |

| 50/50 Blends | 310–330°F | 155–166°C | 15–30 sec | Medium |

| Sublimation on HTV (EasySubli, Glitter HTV, etc.) | 340–360°F | 171–182°C | 20–30 sec | Medium |

| Ceramic Mugs (11oz / 15oz) | 385–400°F | 196–204°C | 180–240 sec | Medium to Firm |

| Tumblers (20–30oz, metal) | 375–390°F | 190–199°C | 240–360 sec | Medium |

| Ceramic Tiles | 380–400°F | 193–204°C | 300–720 sec | Medium |

| Glass (photo panels, cutting boards) | 400–425°F | 204–218°C | 300–420 sec | Medium |

| Metal Photo Panels (Aluminum, Unisub) | 400–425°F | 204–218°C | 60–90 sec | Medium |

| Wood / MDF Hardboard | 385–400°F | 196–204°C | 60–90 sec | Medium |

| Neoprene (mousepads, coasters) | 380–400°F | 193–204°C | 40–50 sec | Medium |

| Canvas | 185–190°F | 85–88°C | 40 sec | Medium |

| Face Masks (poly) | 240–245°C | 464–473°F | 45 sec | Medium |

| Acrylic | 370–400°F | 188–204°C | 40–60 sec | Medium |

| Leather (coated) | 380–400°F | 193–204°C | 40–60 sec | Light to Medium |

| Linen | 380–400°F | 193–204°C | 40–60 sec | Medium |

| Nylon | 375–390°F | 190–199°C | 35–45 sec | Light to Medium |

Materials and Tools Used in Sublimation

- 100% polyester shirts

- Poly-blend shirts

- Ceramic mugs

- Metal tumblers

- Glass blanks

- MDF panels

- Sublimation paper

- Sublimation ink

- Heat-resistant tape

- Protective paper

- Pressing pillow

- Infrared thermometer

- Silicone sleeves

- Heat Press Machine

7 Pro Tips for Mastering Heat Press Temperature

Achieving perfect sublimation results depends heavily on precise temperature control. Follow these expert tips to ensure vibrant, long-lasting transfers every time:

1. Always Start with Manufacturer Guidelines

- Check the recommended temperature range for your specific substrate (mug, shirt, etc.).

- Begin at the lower end of the range and adjust gradually to avoid scorching or fading.

2. Use the Gradual Increase Method

- Start with a low temperature and increase in 5–10°F (3–5°C) increments between test presses.

- This prevents overheating and helps find the sweet spot for color vibrancy.

3. Balance Time & Temperature

- Lower temp? Increase press time slightly.

- Higher temp? Reduce press time to avoid dye migration or scorching.

- Example: 380°F for 45 sec vs. 400°F for 30 sec (adjust based on material).

4. Adjust for Different Materials

- Polyester fabric: Higher polyester content = slightly lower temps.

- Ceramics/Metals: Require steady heat for full ink penetration.

- Plastics/Hardboard: Easily damaged—strictly follow guidelines.

5. Test, Test, and Test Again!

- Never skip test prints—waste one blank to save a whole batch.

- Keep a log of settings (temp, time, pressure, results) for future reference.

6. Prevent Dye Migration & Scorching

- Dye migration (color bleeding) happens when heat is too high, stay within recommended ranges.

- Scorching/yellowing? Reduce temperature or press time.

- Blurry prints? Likely too much heat or shifting during pressing.

7. Use Extra Heat Press Hacks

- Pre-press fabrics to remove moisture and wrinkles.

- Verify actual temp with an infrared thermometer (heat press dials can be inaccurate).

- Cold peel vs. hot peel? Follow transfer paper instructions for best durability.

Final Tip: Consistency is Key!

- Small adjustments make a big difference, track your settings and refine over time.

🔥 Master these tips, and your sublimation prints will always look professional and vibrant!

If you’re new to this craft, you can start with our Introduction to Sublimation Printing to understand the basics before dialing in your heat press settings.

Heat Press Settings Comparison Table

| Product | Temperature (°C) | Time | Pressure |

|---|---|---|---|

| Polyester Fabric | 200 to 205 | 35 to 40 seconds | Medium |

| Ceramic Mugs | 190 to 200 | 20 seconds | Medium to Firm |

| Ceramic Plates | 190 to 200 | 60 seconds | Medium |

| Metal Tumblers | 160 to 170 | 25 seconds | Medium to Firm |

| Umbrellas | 190 to 195 | 45 seconds | Medium |

| Neoprene Items | 200 to 205 | 40 seconds | Medium |

| Metal Items | 190 to 200 | 60 seconds | Medium |

| Face Masks | 240 to 245 | 45 seconds | Medium |

| Over Heat Transfer Vinyl | 175 to 180 | 30 to 35 seconds | Medium |

| Canvas | 185 to 190 | 40 seconds | Medium |

| Polyester Cushions | 200-205 | 35 to 40 seconds | Medium |

Tips:

- – Pre-press fabric for 5-10 seconds before printing.

- – Let mugs cool on the press for 1 minute after pressing.

- – Remove plastic coating from ceramic plates before pressing.

- – Use thermal tape on curved surfaces of metal tumblers.

- – Avoid contact with plastic parts when sublimating umbrellas.

- – Thoroughly clean the press before sublimating neoprene items.

- – Use an absorbent sheet in the press for metal items.

- – Remove the inner cotton layer from face masks if present.

- – Apply vinyl first and let it cool before sublimating over heat transfer vinyl.

- – Pre-press canvas before sublimating.

- – Pre-press polyester cushions like a shirt.

Fabric Prep and Test Press Setup

A fast pre-press and a simple test print save more blanks than any single trick. Once your fabric is flat, dry, and clean, your colors come out sharper and your press behaves predictably every time.

How to Prep Your Fabric Before Pressing

- Pre-press for 3–5 seconds to release hidden moisture and smooth the fibers.

- Lint roll thoroughly, especially on polyester, so no blue dots burn into the print.

- Slide a pressing sheet inside the shirt to stop ink bleed-through.

- Keep the print area flat by shifting the shirt so seams, collars, and hems aren’t under the platen.

How to Set Up a Proper Test Press

- Use a small scrap or test square from the same fabric or shirt batch.

- Check temperature accuracy with an infrared thermometer across multiple points.

- Adjust one variable at a time (temp, time, or pressure) so you know what fixed the issue.

- Record your results in a log with the final settings that worked best.

Want better color accuracy? Switch to ICC color profiles tailored to your printer and ink combo. Also, if you’re working on cotton, use HTV, EasySubli, or coated polysheets to make the design stick.

Shirt Sublimation Settings (Polyester, Blends, HTV)

Getting shirts right comes down to how much polyester is in the fabric and how evenly your press holds heat. Different blends react differently, so the settings that make a 100% poly tee pop won’t look the same on a 65/35 or anything mixed with cotton. Use these ranges as your starting point, then fine-tune based on how your press behaves.

Best Heat Press Settings for Shirts by Fabric Type

| Fabric Type | Temp (°F) | Temp (°C) | Time | Pressure | Notes |

|---|---|---|---|---|---|

| 100% Polyester | 380–400°F | 193–204°C | 45–60 sec | Medium | Brightest colors, least risk if pre-pressed |

| 65/35 Poly-Cotton | 375–385°F | 190–196°C | 25–40 sec | Medium | Slightly muted colors, avoid over-pressing |

| 50/50 Blends | 310–330°F | 155–166°C | 15–30 sec | Medium | Soft vintage look, can scorch easily |

| Tri-Blends | 315–335°F | 157–168°C | 20–30 sec | Light–Medium | Expect lighter colors, test first |

| Sublimation on HTV (EasySubli, Glitter HTV) | 340–360°F | 171–182°C | 20–30 sec | Medium | Great for cotton shirts, sharper details |

| Performance Shirts (athletic poly) | 370–385°F | 188–196°C | 35–45 sec | Medium | Pre-press required due to moisture |

What to Expect With Each Fabric

100% Polyester

This is where sublimation looks its best. Colors lock into the fibers and stay bright wash after wash. If prints look faded, your press is almost always running cooler than the display.

Poly-Cotton Blends

They sublimate, but the cotton doesn’t hold ink. That’s why the design looks softer or slightly washed out. Stick to lower temps to avoid yellowing around the seams.

50/50 and Tri-Blends

These give a vintage look by nature. Shorter press times help prevent sheen marks, especially on heather shirts.

HTV Sublimation for Cotton

If you’re working with cotton, use EasySubli, white glitter HTV, or a sublimation coating. This gives you polyester-like results without destroying the shirt.

How to Prep Shirts Before Pressing

- Pre-press for 3–5 seconds to remove moisture and flatten the fibers.

- Lint roll twice. A single speck of lint will bake into a permanent blue dot.

- Use protective paper above and below the shirt so ink doesn’t bleed.

- Secure the transfer with heat tape if your press shifts when closing.

These tiny steps solve most ghosting, fading, and blotching issues before they ever start.

Pro Tip From Real Shop Workflow

If your seams, collars, or shoulders create uneven pressure, slide a pressing pillow inside the shirt. It raises the print area so the platen comes down evenly. This one move fixes 80% of “random light spots” on blended shirts.

Can you sublimate at 325 degrees?

No, you cannot sublimate at 325 degrees Fahrenheit. The ideal temperature for sublimation is between 380-400 degrees Fahrenheit. At 325 degrees Fahrenheit, the dye cannot vaporize and transfer to the substrate.

If you try to sublimate at 325 degrees Fahrenheit, you will likely have a blurry or faded image. In some cases, the image may not transfer at all.

To achieve the best results, use above given range when sublimating. First test your settings on a scrap piece of material for better outcome.

For a full step-by-step walkthrough of equipment, setup, and workflow, check out our complete Sublimation Printing How-To Guide.

Mug & Tumbler Time and Temperature Guide

Sublimating mugs and tumblers feels simple until you realize every press heats a little differently. Ceramic needs steady, even heat. Metal warms slower. And convection ovens run hotter around the edges than the center. These settings give you a reliable starting point for the most common drinkware blanks so you can avoid faded panels, cold spots, or overcooked coatings.

Recommended Settings for Mugs & Tumblers

| Item Type | Temp (°F) | Temp (°C) | Time | Pressure | Notes |

|---|---|---|---|---|---|

| 11 oz Ceramic Mug | 385–400°F | 196–204°C | 180–240 sec | Medium–Firm | Full wrap needs firm pressure for clean edges |

| 15 oz Ceramic Mug | 385–400°F | 196–204°C | 180–240 sec | Medium–Firm | Larger surface holds heat longer |

| Frosted Glass Mugs | 385–395°F | 196–201°C | 180–210 sec | Light–Medium | Easy to scorch, go lower if browning |

| 20 oz Metal Tumbler | 375–390°F | 190–199°C | 240–360 sec | Medium | Rotate halfway if using convection |

| 30 oz Metal Tumbler | 375–390°F | 190–199°C | 300–420 sec | Medium | Heat distribution varies by brand |

| Enamel Camping Mugs | 375–385°F | 190–196°C | 120–180 sec | Light | Too much pressure dents enamel edges |

| Glass Can Cups | 380–390°F | 193–199°C | 180–240 sec | Light–Medium | Cool slowly to prevent cracking |

How to Get Cleaner, Sharper Wraps

Full wraps only work when pressure hugs the blank evenly. If the edges look faded or the middle looks lighter, your press isn’t applying uniform pressure.

Try this:

- Tighten the press until you hear slight resistance closing.

- Make sure the seam faces directly away from the heating element.

- Tape the transfer with three points: top, bottom, and seam area.

- Use a silicone sleeve for metal tumblers if you see “cold” vertical lines.

Convection Oven Settings for Tumblers

If you’re using a convection oven instead of a mug or tumbler press, go with:

- Temperature: 375–400°F (190–204°C)

- Time: 5–7 minutes

- Rotation: Turn halfway for even heating

- Sleeve: Use heat shrink wraps for pressure

Ovens give incredibly even color but require slightly longer heating because there’s no direct platen contact.

Avoiding the Most Common Mug Mistakes

A few simple habits fix almost every mug problem people run into:

- If the print looks faded: You didn’t use enough pressure or your press runs cool.

- If the handle area looks light: Rotate the mug slightly next time so that side gets direct heat.

- If colors look brownish: You cooked it too long, especially with pink, red, or skin tones.

- If there are tiny white dots: Moisture didn’t escape, so preheat the mug for 5–10 seconds next time.

Quick Pro Tip

Most mug presses run cooler than the display by about 5–20°F. If your prints never look as vibrant as expected, check with an IR thermometer. One quick measurement can save a whole case of mugs.

Hard-Surface Sublimation (Metal, Glass, MDF)

Hard surfaces behave differently from fabrics because they absorb heat slowly and release it just as slowly. That’s why these blanks need longer press times and steadier temperatures. When the heat soaks all the way through the coating, the colors lock in cleanly with no banding, blotches, or cold spots.

Recommended Settings for Hard-Surface Blanks

| Material | Temp (°F) | Temp (°C) | Time | Pressure | Notes |

|---|---|---|---|---|---|

| Metal Photo Panels (Aluminum, Unisub) | 400–425°F | 204–218°C | 60–90 sec | Medium | Press face-up, use protective sheet |

| Glass Photo Panels | 400–425°F | 204–218°C | 300–420 sec | Medium | Slow cooling prevents cracking |

| Cutting Boards (Glass) | 400°F | 204°C | 240–300 sec | Medium | Press from the back (print side down) |

| MDF / Hardboard (Signs, Plaques) | 385–400°F | 196–204°C | 60–90 sec | Medium | Keep sheet tight to avoid soft edges |

| Coasters (Stone, Fiberboard) | 390–400°F | 199–204°C | 45–75 sec | Medium | Use a silicone pad underneath |

| Acrylic Blanks (Coated) | 370–400°F | 188–204°C | 40–60 sec | Light–Medium | Remove film, avoid warping by cooling flat |

How to Press Hard Surfaces Correctly

Metal Panels

Metal heats up fast but cools unevenly. Press them face up with a clean sheet on top so the ink doesn’t blow out at the edges. A warm peel gives cleaner lines.

Glass Panels

Glass needs long, consistent heat. Press from the back side so the ink infuses through the coating. Avoid sudden temperature changes or you’ll risk hairline cracks.

MDF / Hardboard

These often bow if they’re heated unevenly. Use a silicone pad underneath to distribute heat and keep the surface flat.

Preventing the Most Common Hard-Surface Issues

Here’s what usually goes wrong and what fixes it:

- Blotchy color: Pressure wasn’t even, or the surface wasn’t fully flat.

- Faded corners: The press or oven has cold spots. Move the blank toward the center next time.

- Yellowing edges: Too much time or the coating overheated. Reduce by 10°F or cut 10–20 seconds.

- Surface warping: Cool the blank on a flat, heavy board to keep it straight.

Real Example from Production

One shop kept getting faded stripes on aluminum panels. An infrared check showed the top-left corner of their press was 22°F cooler than the display. They repositioned the panels toward the center and cut failures by over half in the first day. Small details like this are the difference between perfect displays and wasted blanks.

Quick Pro Tip

Always let glass and metal cool slowly. Fans, cold surfaces, or quick handling can cause micro-cracks or dull spots that don’t show up until after the first wash or display.

Why Temperature Variance Happens (Calibration Guide)

Every heat press has its own personality. Some run hotter than the display, some run cooler, and a few swing up and down during a single press. If your prints look faded, overcooked, or inconsistent even when you follow the charts perfectly, temperature variance is almost always the real reason.

Why Heat Presses Don’t Match Their Display

1. Inaccurate factory thermostats

Budget presses often ship with inexpensive sensors. They read the temperature at the thermostat, not the actual platen surface where your blank sits.

2. Hot and cold zones across the platen

It’s normal for the center to be hotter than the edges by 10–25°F. This is why the middle of a shirt pops with color while the corners look soft.

3. Heat loss when the press opens

The longer your press stays open between items, the more temperature swings you’ll see. Those swings show up instantly in your prints.

4. Age and wear on heat coils

Older presses warm unevenly. You might get stripes or patches where the color looks weaker.

How to Check Your Real Temperature (Quick Calibration)

You can figure out what your press is really doing in just a couple minutes.

- Use an infrared thermometer and take readings across the surface: top-left, top-right, center, bottom-left, bottom-right.

- Compare these numbers with your press’s digital display.

- If you see a difference greater than 10–15°F, adjust your settings or reposition your blanks toward the center.

- Repeat readings every few weeks if you press daily.

What to Adjust When Your Press Runs Hot or Cold

If your press runs hot:

- Lower temp by 10–15°F

- Reduce press time by 5–10 seconds

- Watch for yellowing around seams

If your press runs cold:

- Increase temp by 10–20°F

- Increase time slightly (5–15 sec)

- Faded colors are your biggest clue

Real Shop Example

A customer pressed polyester shirts at 400°F, but the colors kept coming out dull. When we checked their press with an IR thermometer, the platen was actually 362–370°F. After raising the set temperature to 415°F, the shirts finally hit the target range and the print vibrancy jumped noticeably.

Quick Pro Tip

Once you find the sweet spot for your press, write it down. Every model behaves differently, and dialing in your “true temp” is the easiest way to get consistent, studio-quality color every time.

How to Calibrate Your Heat Press for Accurate Sublimation

Accurate temperature is the difference between sharp, vibrant prints and washed-out colors. Here’s the simple calibration process used in production shops to make sure your press hits the correct temperature every time.

1. Pre-press the fabric or test material

Press your test fabric for 3–5 seconds to clear moisture and flatten the surface. This keeps your calibration results clean.

2. Clean the test area

Lint, dust, and loose fibers can spoil test prints. Roll the fabric thoroughly before placing your transfer.

3. Position the transfer and protect the surface

Add protective paper inside and on top of the shirt. Tape the transfer so it won’t shift when the press closes.

4. Run a quick test press

Use your normal sublimation settings on a small scrap piece. Look for dull colors, faded spots, or uneven transfers.

5. Measure the platen temperature

Use an infrared thermometer to check multiple spots:

- Center

- Top left

- Top right

- Bottom left

- Bottom right

If any area is off by more than 10–15°F, your display isn’t accurate.

6. Adjust your temperature settings

- If your heat press runs cold, increase set temp by 10–20°F.

- If it runs hot, reduce the set temp by 10–15°F.

Make small adjustments until your real surface temp matches your target.

7. Save your temperature presets

Once your press consistently reaches the right heat:

- Polyester shirts → 380–400°F

- Mugs → 385–400°F

- Metal panels → 400–425°F

Save these as presets if your press allows it.

8. Print your actual item

After calibration is dialed in, run your real sublimation print for consistent and vibrant results.

Common Sublimation Problems Caused by Wrong Temperature

Most sublimation issues trace back to heat that’s either too high, too low, or uneven across the platen. Even a 10–15°F swing can change how the ink transfers. If your colors, edges, or textures look off, this section helps you pinpoint the exact temperature mistake behind the result.

1. Faded or Washed-Out Colors

This is the classic sign your press is running too cool or the heat isn’t reaching the coating evenly.

What it looks like:

Soft edges, dull colors, light patches, or incomplete transfers.

Fix it:

- Increase temp by 10–20°F

- Add 5–15 seconds of press time

- Move the blank toward the center of the platen

- Check actual heat with an IR thermometer

2. Overcooked or Brownish Prints

Heat that’s too high “cooks” certain dyes, especially reds, skin tones, and light pastels.

What it looks like:

Brown tint, burnt-looking shadows, or yellow stains around seams.

Fix it:

- Lower temp by 10–15°F

- Cut 10–20 seconds off your time

- Pre-press briefly to remove moisture

3. Ghosting or Double-Shadows

This happens when the paper shifts or the ink re-gasses after the press opens.

What it looks like:

A faint second image, blurred edge, or light shadow next to the design.

Fix it:

- Tape the transfer firmly

- Increase pressure slightly

- Open the press smoothly, don’t jerk

- Let the paper cool before removing

4. Blotchy or Patchy Transfers

Uneven heat zones or moisture pockets cause these random light spots.

What it looks like:

Small irregular patches where color didn’t bond.

Fix it:

- Pre-press the material for 3–5 seconds

- Use a silicone pad under hard surfaces

- Take multiple temperature readings across the platen

5. Banding or Lines in the Print

This usually means the coating didn’t reach full activation temperature.

What it looks like:

Horizontal or vertical lines, mostly on metal panels or tumblers.

Fix it:

- Increase heat or time slightly

- Rotate the tumbler during oven presses

- Shift the panel away from cold edges

6. Warping or Bowing (Hard Surfaces)

Too much heat for too long bends MDF, acrylic, and even metal.

What it looks like:

Curved edges, lifted corners, uneven prints.

Fix it:

- Lower temp

- Add a cooling board after pressing

- Use medium pressure rather than firm

Quick Pro Tip

Whenever you troubleshoot, change only one variable at a time. If you adjust temp, time, and pressure all at once, you won’t know which fix worked. One small tweak usually solves the whole issue.

Pro Tips from Real Production Work

Smart workflows beat trial and error. Once you master temperature, moisture, pressure, and alignment, your sublimation setup becomes predictable, and that’s when prints start looking truly professional.

1. Trust the Print, Not the Display

Most heat presses lie by 10–25°F. Always spot-check the platen with an infrared thermometer. If colors look weak, assume the press is cooler than it claims and bump the temp a little.

2. Pre-Press Anything That Can Hold Moisture

Polyester shirts, neoprene, canvas, and linen carry moisture you can’t see. A quick 3–5 second pre-press stops ghosting, blotching, and random blue dots.

3. Tape Like You Mean It

If your transfer shifts even a millimeter, you get ghosting. Use heat tape at the top, bottom, and seam area. For tumblers, wrap snugly and use two anchor points.

4. Keep a Settings Log

Every material has a sweet spot. Record temp, time, pressure, and results. In a month, you’ll have a custom “Bible” for your press—and fewer ruined blanks.

5. Press Shirts Off the Seams

Buttons, collars, hems, and shoulder seams lift the platen and cause uneven color. Slide a pressing pillow inside or shift the shirt so the print area sits perfectly flat.

6. Cool Hard Surfaces Slowly

Metal and glass crack, cloud, or warp if cooled too fast. Move them to a flat surface and let them settle naturally. No fans, no cold tables.

7. Rotate Tumblers in Ovens

Oven heat circles the chamber unevenly, so rotate once halfway through. It’ll fix those vertical “cold lines” instantly.

8. Replace Blowout Paper Often

Reusing protective sheets traps ink and leaves faint old designs on new prints. Fresh paper keeps everything crisp.

9. Don’t Over-Press to “Fix” Dull Prints

If colors look weak, increase heat slightly—not time. Too much time washes the design out and can brown the coating.

10. When in Doubt, Test a Scrap

A single wasted blank is better than a wasted box. Quick tests pay for themselves in fewer failures and faster workflows.

Care and Longevity Tips

The right press settings don’t just make your prints look good, they help them last longer too. But care after pressing matters just as much.

For apparel, always wash in cold water, turn garments inside-out, and avoid bleach or harsh detergents. This preserves both color and fabric quality over time.

Hard-surface items like mugs, tumblers, and metal signs should be hand-washed only. Dishwashers can wear down the coating and fade the design early.

When temperature, time, and pressure are dialed in correctly during sublimation, the transfer bonds deep into the surface. That’s what gives your prints their sharp edges and long-lasting vibrancy, wash after wash, sip after sip.

6 Comments