DTG vs Screen Printing: Which Is Best for You?

DTG and screen printing are two popular ways to print designs on fabric. DTG uses inkjet technology to spray water-based inks directly onto garments, making it great for small orders and detailed designs.

Screen printing pushes ink through stencils, offering vibrant, durable prints at lower costs for bulk orders. The best choice depends on quantity and style needs.

| Method | How It Works | Best For | Key Advantage |

|---|---|---|---|

| DTG Printing | Digital inkjet sprays ink directly on fabric | Small runs, detailed or colorful designs | No setup, photo-like prints |

| Screen Printing | Ink pushed through stencils (screens) onto fabric | Bulk orders, bold and simple graphics | Durable, cost-effective in bulk |

How Each Method Works

DTG is like printing a photo straight onto fabric, while screen printing is layering ink by hand through stencils. The tools and steps differ, but both can deliver professional results when matched to the right project.

What is DTG Printing?

DTG (Direct-to-Garment) works almost like an oversized desktop inkjet, but instead of paper, you’re printing on fabric.

Steps in the process:

- Pre-treatment: The shirt is sprayed with a solution that helps the ink bond and stay vibrant.

- Printing: A digital printer sprays water-based inks directly onto the fibers.

- Curing: Heat is applied (usually with a heat press or tunnel dryer) to set the inks and lock in color.

DTG is ideal for small batches, detailed designs, and lots of colors, because there’s no need to prepare separate screens.

If you’re curious how it performs on darker garments, check out our guide on DTG on black shirts to see tips for getting the best results.

What is Screen Printing?

Screen printing is more traditional and hands-on. It’s all about pushing ink through a stencil (called a screen) onto the garment.

Steps in the process:

- Screen prep: A mesh screen is coated with emulsion and exposed to light to create the stencil.

- Inking: Ink is spread across the screen with a squeegee, pressing it through open areas of the stencil.

- Layering: Each color in the design requires its own screen and pass.

- Curing: The garment goes through a dryer to harden the ink.

Screen printing is best for bulk runs and bold designs, since setup takes time but becomes cost-effective once you print many items.

If you’re comparing other methods too, our breakdown of sublimation vs screen printing shows how dye-sub stacks up.

Tools, Inks, and Materials Used

- DTG: Digital printer, pre-treatment solution, water-based CMYK inks, cotton or cotton-rich garments.

- Screen Printing: Mesh screens, emulsion, squeegees, plastisol or water-based inks, dryers, and almost any fabric type including cotton, polyester blends, and synthetics.

Key Differences & Comparison Metrics

DTG is your go-to for complex, colorful designs where softness matters, while screen printing is the best choice for bold, durable graphics, especially in bulk. Matching the method to the type of design and fabric is what guarantees the best result.

| Metric | DTG Printing | Screen Printing |

|---|---|---|

| Design Complexity | Handles gradients, photo-like images, and unlimited colors with ease | Best for simple, bold designs with limited colors |

| Color Range | Full CMYK, can print detailed artwork without extra setup | Each color requires a separate screen, setup increases with more colors |

| Feel & Finish | Soft, almost “no feel,” ink soaks into fibers | Thicker or raised, sharper edges, vibrant finish depending on ink choice |

| Durability | Good on cotton, may fade faster after many washes, especially on dark garments | Excellent longevity, resists fading and cracking with proper curing |

| Best Fit | Small runs, custom artwork, detailed logos, multicolor designs | Bulk orders, uniforms, merch, and designs meant to last through heavy use |

DTG durability depends heavily on the fabric and the curing process. On 100% cotton, prints can last a long time, but they may fade faster than screen prints after repeated washing. Dark shirts also need a white underbase layer with DTG, which can affect how long the design holds up.

Pros and Cons

| Method | Pros | Cons |

|---|

| DTG Printing | Great for detailed, colorful designs. Soft feel on fabric. No setup costs. | Less durable on dark fabrics. Slower for bulk orders. |

| Screen Printing | Extremely durable. Cost-effective for large runs. Bold, vibrant colors. | High setup cost. Not ideal for complex or multi-color designs. |

Best For

| Method | Best For |

|---|---|

| DTG Printing | Small orders, one-off designs, detailed artwork, photo prints, multi-color logos |

| Screen Printing | Bulk orders, team uniforms, company merch, simple bold graphics, long-term durability |

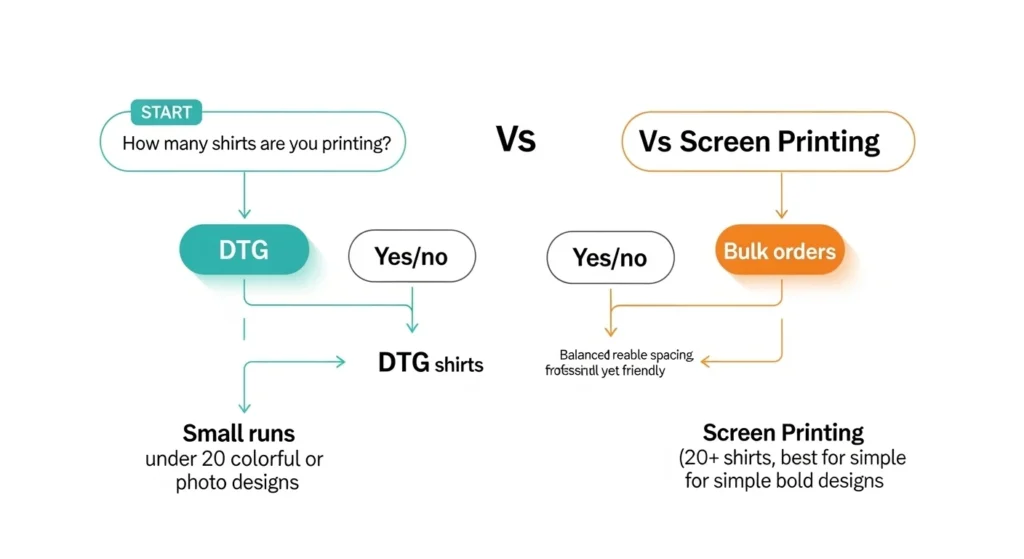

Which One Should You Pick?

Think of this as a cheat sheet. Instead of digging through every detail, here’s the no-nonsense way to decide:

- If you only need a few shirts (like under 20) → Go DTG. No setup drama, just print and go.

- If you’re testing a design or doing one-offs (like a birthday shirt or a sample for your brand) → DTG is the clear winner.

- If your design is full of colors, gradients, or even a photo → Stick with DTG. Screen printing can’t handle that detail without costing extra.

- If you’re printing for a big event, team, or business (50+ shirts) → Choose Screen Printing. The per-shirt price drops a lot once you hit bulk.

- If your design is simple (like bold text or 1–2 colors) → Screen Printing will give you vibrant, long-lasting prints for less.

- If you’re worried about upfront costs and don’t want to commit to a big order → DTG is safer. No minimums.

- If you want the toughest, most durable print that’ll survive years of washing → Screen Printing takes the crown.

Friend-to-friend advice:

- DTG is like ordering à la carte, great for small, colorful, personal projects.

- Screen printing is like buying wholesale, better when you need a bunch of the same thing.

Speed & Turnaround Time

DTG is fast and flexible for small, detailed runs. Screen printing is slower to start but unbeatable for bulk orders.

Small orders

- DTG usually wins, since you can print a few shirts in minutes with no screens to burn.

- Perfect if someone wants a handful of custom tees for an event or gift.

Large orders

- Screen printing shines once the setup is done. Printers can knock out hundreds of shirts quickly, often faster than DTG at scale.

- Great for teams, events, or retail stock.

Design complexity

- Detailed, colorful designs take the same time on DTG, since it prints like a photo.

- Screen printing slows down if you add more colors, because each layer adds prep and printing steps.

Fabric Types & Compatibility

For soft, photo-like prints on cotton, DTG is best. For durability across a wider range of fabrics and colors, screen printing offers more flexibility, especially on synthetics and darker garments.

Best fabrics for DTG:

DTG works best on 100% cotton or cotton-rich blends. Natural fibers absorb the water-based inks well, which helps colors pop and keeps the print soft. Dark shirts need a white underbase layer, which adds a tiny bit of thickness to the design but ensures accurate colors.

Screen printing and fabric versatility:

Screen printing is more flexible when it comes to fabric types. It works well on cotton, polyester blends, synthetic fabrics, and performance materials. Plastisol inks sit on top of the fabric, so they don’t rely on absorption. That makes screen printing ideal for sports jerseys, polyester merch, or any fabric that won’t absorb water-based inks properly.

Color of the garment

- Light fabrics: Both DTG and screen printing show colors vividly with no extra steps.

- Dark fabrics: DTG requires a white underbase for full-color designs, while screen printing can use opaque inks to achieve the same effect. Darker colors may show the print differently depending on ink type and layering, so testing is recommended.

Just remember that proper conditions matter, and maintaining the best room temperature for screen printing helps avoid wasted prints.

Durability in Real-World Use

Screen printing is your go-to for long-lasting, heavy-use garments. DTG works best for short-to-medium-term wear or detailed designs where softness matters, but proper care is key to keeping prints vibrant.

How they withstand wear and washing:

Screen printing generally takes the lead in durability. Prints can handle repeated washing, sun exposure, and stretching without fading or cracking if cured properly. DTG prints are softer and more integrated with the fabric but may fade faster over time, especially on dark shirts or heavily washed items.

Special inks and performance

- Plastisol inks (screen printing): Thick, vibrant, and very durable. Ideal for long-lasting designs.

- Water-based inks (both methods): Softer feel, eco-friendly, but may not last as long on dark fabrics.

- Discharge inks (screen printing): Remove shirt dye and replace it with ink for a soft, vintage feel. Very durable on cotton, but limited on blends.

What affects fading, cracking, or peeling

- Fabric type: Natural fibers like cotton hold ink better than some synthetics for DTG.

- Curing process: Under- or over-curing can weaken prints.

- Ink quality: Higher-quality inks last longer and resist cracking.

- Washing and care: Hot water, bleach, or harsh detergents can shorten print life.

Cost vs Benefit: What Fits Your Situation

Match the printing method to your quantity, design complexity, and longevity needs. DTG is great for small, detailed runs, while screen printing dominates bulk orders with simple, durable designs.

When DTG makes sense

- Small batches or one-off shirts

- Custom designs with many colors or gradients

- Low-volume orders where setup cost matters less

DTG lets you print complex, colorful artwork without paying for multiple screens. It’s fast, flexible, and ideal for testing new designs or producing gifts and samples.

When Screen Printing wins

- Bulk orders with 50+ shirts

- Simple designs with 1–3 colors

- Projects requiring long-lasting durability

Screen printing’s upfront setup pays off for large runs. Once the screens are ready, printing hundreds of shirts becomes cost-effective, and the prints stand up to repeated washing and wear.

Hybrid / mixed scenarios

Sometimes a combination works best. For example, a large order with a few photo-like elements can use DTG for the detailed parts and screen printing for solid graphics. This approach balances cost, quality, and efficiency.

| Factor | DTG Printing | Screen Printing |

|---|---|---|

| Order Size | Small runs, one-offs | Medium to large batches (50+ shirts) |

| Design Complexity | Detailed, full-color, photo-like designs | Simple, bold graphics with limited colors |

| Durability | Good, fades faster with frequent washing | Excellent, resists fading, cracking, and peeling |

| Setup Cost | Minimal, no screens required | Higher setup cost due to screens and prep |

| Best Use Case | Custom gifts, samples, low-volume designs | Team uniforms, bulk merch, long-term wear |

Beginners who want to start small might want to explore the best DTG printers designed for newbies.

Other Considerations

Consider the full picture, not just the design or price. Environmental impact, setup, quality control, and local resources can all influence which method is most practical for your project.

Environmental Impact and Sustainability

DTG uses water-based inks and generally produces less waste per shirt, which makes it more eco-friendly for small runs. Screen printing can generate excess ink and chemical waste, especially with plastisol inks, but some eco-conscious printers now offer water-based or low-VOC options.

Setup Investment and Maintenance

DTG printers are expensive upfront and need regular maintenance, like cleaning print heads and replacing cartridges. Screen printing requires investment in screens, squeegees, and curing equipment, plus labor for setup. Each method carries its own risk if your order volume or design needs change unexpectedly.

Quality Control Issues

Color consistency can be tricky. DTG prints may vary slightly between shirts if pre-treatment or curing isn’t uniform. Screen printing can produce minor variations between runs, especially if multiple screens or operators are involved. Testing and sample checks help avoid surprises.

Local Supplier Capabilities and Shipping Costs

Availability of skilled printers and compatible equipment in your area can affect turnaround times and costs. DTG printers might be less common locally, making shipping or sourcing expensive. Screen printing services are widespread, but bulk shipments can add to cost if you need them quickly.

Decision Guide / Checklist

Use this checklist to quickly see which method fits your project. Small, detailed orders lean DTG, while bulk, simple designs lean screen printing. Hybrid approaches can balance both when needed.

Quick Guide by Order Size, Budget, and Design Type

| Scenario | Order Size | Budget Focus | Design Type | Recommended Method |

|---|---|---|---|---|

| One-off custom shirt or gift | 1–10 shirts | Flexible per shirt | Full-color, photo-like | DTG |

| Small brand sample run | 10–25 shirts | Moderate | Multi-color, detailed logos | DTG |

| Large merch production | 50–200+ shirts | Cost per shirt | Bold graphics, limited colors | Screen Printing |

| School or sports uniforms | 50+ shirts | Bulk efficiency | Logos, numbers, team graphics | Screen Printing |

| Mixed designs with custom inserts | Varies | Balanced | Some detailed, some bold graphics | Hybrid: DTG + Screen |

Sample Scenarios

- Starting a clothing brand: DTG is ideal for small test batches to see which designs resonate before investing in screens.

- Producing merch for a band or event: Screen printing often wins once you’re doing dozens of shirts with simple graphics.

- School uniforms: Screen printing is durable, cost-effective, and handles repeated washing.

- One-off gifts: DTG lets you print photo-quality images without committing to bulk orders.

Key Metrics Comparison Table

| Metric | DTG Printing | Screen Printing |

|---|---|---|

| Order Size | Small runs, one-offs | Medium to large batches (50+ shirts) |

| Design Complexity | Detailed, full-color, photo-like designs | Simple, bold graphics with limited colors |

| Durability | Good, fades faster with frequent washing | Excellent, resists fading, cracking, and peeling |

| Setup Cost | Minimal, no screens required | Higher setup cost due to screens and prep |

| Fabric Compatibility | Best on cotton and cotton blends | Works well on cotton, blends, synthetics, performance fabrics |

| Speed & Turnaround | Fast for small orders | Faster on large bulk runs after setup |

| Best Use Case | Custom gifts, samples, low-volume designs | Team uniforms, bulk merch, long-term wear |