Can You Sublimate on Corrugated Plastic? What Works, What Doesn’t, and Why

Corrugated plastic is everywhere, yard signs, event displays, outdoor graphics. Naturally, people ask the same question over and over.

Can you sublimate on corrugated plastic?

The short answer is no, not directly. Corrugated plastic doesn’t absorb sublimation ink the way polyester-based materials do. But with the right coating and setup, it can be made to work for specific projects.

No guessing. No wasted materials.

What Is Corrugated Plastic?

Quick grounding first. This section isn’t about ranking for plastic terms, it’s about making sure we’re talking about the same material.

Corrugated plastic is commonly known as Coroplast. It looks simple, but its structure is the reason sublimation struggles with it.

What corrugated plastic is made of

Corrugated plastic is made from polypropylene, formed into two flat sheets with a fluted layer in between. Think of it like cardboard, but plastic.

Key traits that matter for printing:

- Polypropylene base

- Non-porous surface

- Hollow flutes running through the center

- Lightweight and flexible

None of those are friendly to dye sublimation by default.

Why it’s popular for signs and displays

It’s popular because it’s:

- Cheap

- Lightweight

- Weather-resistant

- Easy to cut and mount

That’s why it dominates yard signs, political signs, and temporary outdoor displays.

How it differs from sublimation-ready plastics

Sublimation-ready plastics always have a polyester coating or polymer layer designed to accept dye gas. Corrugated plastic does not.

If you’re new to what sublimation actually needs to work, this overview of what sublimation printing really is helps connect the dots.

Can You Sublimate on Corrugated Plastic Directly?

Here’s the straight answer.

No, you cannot sublimate on corrugated plastic directly.

Sublimation ink does not bond to raw polypropylene. The ink will gas out during pressing, but it has nowhere to lock in.

What happens if you try anyway:

- Ink looks faded or washed out

- Colors wipe off or scratch away

- Heat can warp the board

- Results are inconsistent at best

This isn’t a settings issue, and it’s not your printer. It’s a material limitation.

Why Corrugated Plastic Rejects Sublimation Ink

This is where trust matters. If you understand the “why,” you won’t keep chasing fixes that don’t exist.

Non-porous polypropylene surface

Sublimation dye needs microscopic pores or a polymer layer to bond with. Polypropylene is slick and closed-off, so the dye just floats and dissipates.

Lack of polyester bonding layer

No polyester means no chemical bond. That’s non-negotiable for sublimation. This is the same reason sublimation struggles on untreated cotton or raw plastics, which we explain deeper in our breakdown of why sublimation colors look dull and fail.

Heat sensitivity and warping risks

Corrugated plastic softens quickly under heat. Pressing at typical sublimation temperatures can:

- Warp the sheet

- Collapse flutes

- Create uneven pressure zones

Even if ink transfers, the board itself may be ruined.

How to Sublimate on Corrugated Plastic (With a Coating)

This is a workaround, not a recommendation.

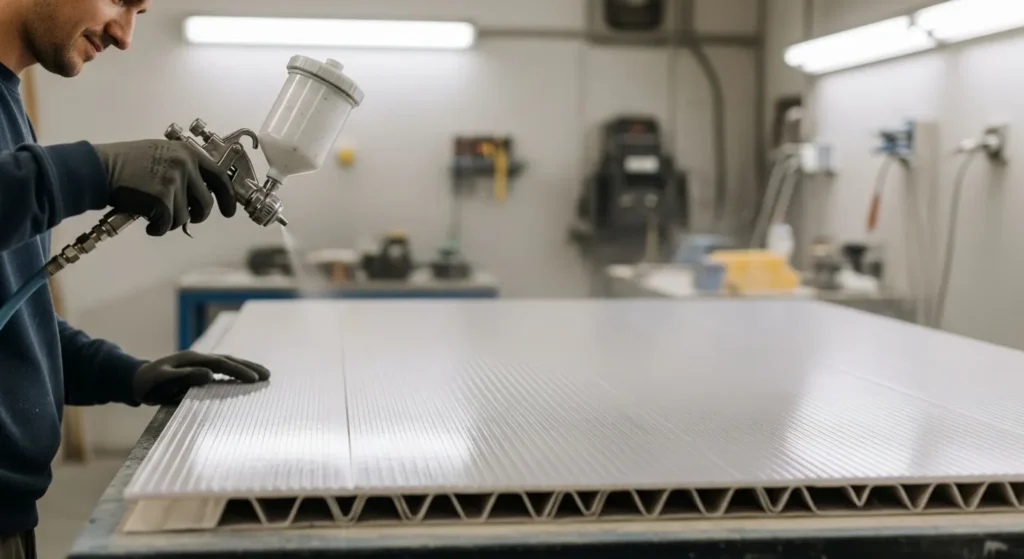

If you absolutely must sublimate onto corrugated plastic, a polyester coating is required, and expectations need to stay realistic.

1. Surface preparation and cleaning

Before coating:

- Clean thoroughly with isopropyl alcohol

- Remove oils, dust, and residue

- Allow to fully dry

Skipping prep almost guarantees failure.

2. Polyester spray coatings explained

Polyester spray coatings create a thin polymer layer that sublimation ink can bond to. They work, but they’re:

- Time-consuming

- Costly per piece

- Prone to uneven application

This is similar to other coating-based methods covered in our guide on using sublimation coating liquids.

3. Heat press settings and handling

If coated:

- Use lower pressure

- Shorter dwell times

- Protective paper on both sides

- Support board underneath to reduce fluting collapse

Even then, warping risk remains.

Common mistakes during coated sublimation

Most failures come from:

- Uneven coating thickness

- Overheating

- Pressing without rigid backing

- Expecting outdoor durability

This method is best for short-term indoor use only.

Common Problems When Sublimating Corrugated Plastic

Even with coatings, issues are common.

Ink bleeding and color dullness

Coatings can cause:

- Dye spreading

- Muted colors

- Patchy saturation

Especially noticeable on large solid areas.

Warping and surface distortion

Heat plus hollow flutes equals distortion. Once warped, the board rarely flattens again.

Uneven transfers from fluted structure

Pressure inconsistency across flutes leads to:

- Light bands

- Blotchy areas

- Incomplete transfers

If you’re seeing repeated defects, this troubleshooting guide for common sublimation printing problems helps rule out other causes.

When Sublimation Is the Wrong Choice for Corrugated Plastic

This is where being honest helps your business.

Sublimation is the wrong choice when:

- The sign will be outdoors

- Longevity matters

- You’re producing in volume

- Cost per unit matters

Coating plus labor often costs more than better printing methods with shorter lifespans.

Many of these limitations apply to plastic materials in general, not just corrugated sheets.

Our full breakdown of what plastics can be sublimated explains this in more detail.

Best Alternatives to Sublimation for Corrugated Plastic

If corrugated plastic is the substrate, these options make more sense.

UV printing

UV ink bonds directly to polypropylene and cures instantly. It’s:

- Durable

- Weather-resistant

- Ideal for professional signage

Vinyl graphics and decals

Vinyl works great for:

- Yard signs

- Short runs

- Multi-color designs

It’s also easier to replace and update.

Screen printing for bulk signs

For large quantities with simple designs, screen printing is cost-effective and durable. We compare this method against others in our breakdown of sublimation vs screen printing.

Common Uses for Printed Corrugated Plastic

Corrugated plastic shines when expectations match reality.

Common uses include:

- Yard signs

- Political and campaign signage

- Event signage

- Temporary directional signs

- Construction and safety notices

These are applications where durability is “good enough,” not permanent.

FAQs:

Can you sublimate on corrugated plastic sheets?

No, not directly. Corrugated plastic sheets are made from polypropylene, which doesn’t bond with sublimation ink. Without a polyester coating, the ink won’t lock in and will fade, wipe off, or fail completely.

Can you print on corrugated plastic?

Yes, but not with sublimation alone. Corrugated plastic can be printed using UV printing, screen printing, or vinyl graphics. These methods bond mechanically or cure on the surface, which works much better for this material.

Can you sublimation print on plastic?

Only on plastics that have a polyester coating or are specifically labeled as sublimation-ready. Raw plastics like polypropylene, polyethylene, or PVC will reject sublimation ink unless they’re coated first.

What is the melting point of corrugated plastic?

Corrugated plastic, typically polypropylene, begins to soften around 248–266°F (120–130°C). This is lower than standard sublimation temperatures, which is why warping and distortion are common during heat pressing.

Is corrugated plastic heat resistant?

Not really. It can tolerate mild heat, but it’s not designed for sustained high temperatures. Heat presses used for sublimation can easily cause bending, fluting collapse, or surface deformation.

What materials can you not sublimate on?

You cannot sublimate directly on materials that lack a polyester layer. This includes:

- Pure cotton

- Untreated wood

- Raw plastics like polypropylene

- Silicone

- Leather without coating

- Dark or black substrates without a white polyester layer