Sublimation Temperatures: Nail Perfect Prints with Easy Charts

Sublimation printing can turn your mugs and tees into vibrant masterpieces, but getting the temperatures and times right is a real pain, right? One wrong setting and your design’s faded or your shirt’s toast.

The best sublimation temperature range is 190–204°C (374–399°F), with a medium pressure (35–40 psi) and 40–60 seconds for polyester fabrics.

Mugs need 193–204°C for 3–4 minutes in a press or 190°C for 12–15 minutes in a convection oven.

These settings give vibrant colors and prevent ghosting or scorch marks.

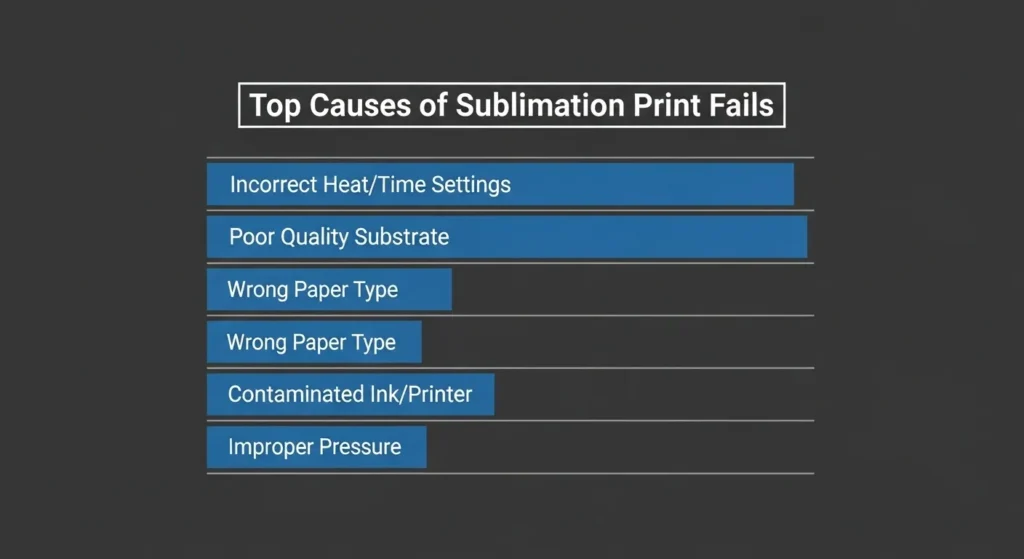

With 80% of sublimation fails tied to incorrect heat settings, you need clear, no-BS guidance. This post breaks down the exact temps, times, and tips for perfect prints, If you’re using a heat press or convection oven. Stick around for practical, beginner-friendly advice that’ll save you time and costly oops moments.

Quick Sublimation Heat Settings

- Polyester Shirts: 190–204°C | 40–60s | Medium Pressure

- Mugs (Press): 193–204°C | 180–240s | Medium-Firm

- Mugs (Oven): 190°C | 12–15m | Shrink Wrap

- Tumblers: 182–190°C | 5–6m | Rotate

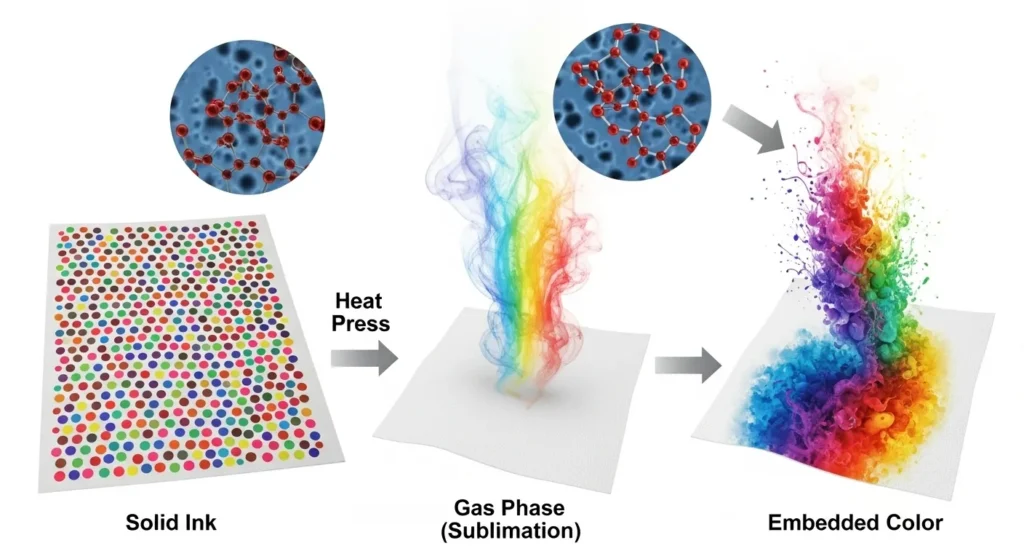

Sublimation: The Science of Heat and Ink

Sublimation printing turns ink into gas, bonding it to polyester or coated surfaces like mugs for vibrant, lasting designs. It’s tricky, though, mess up the heat, time, or pressure, and your print’s faded or scorched.

About 90% of pro sublimation uses polyester-based materials for their ink-grabbing power. Precision is everything: too low a temp (under 180°C) dulls colors, too high (over 210°C) causes ghosting or burns. Test on scrap first, blanks cost $5-$10!

Key factors:

- Temp: 190-204°C for most items

- Time: 40-60s for shirts, 3-15m for mugs

- Pressure: Medium (35-40 psi)

- Material: High polyester or coated

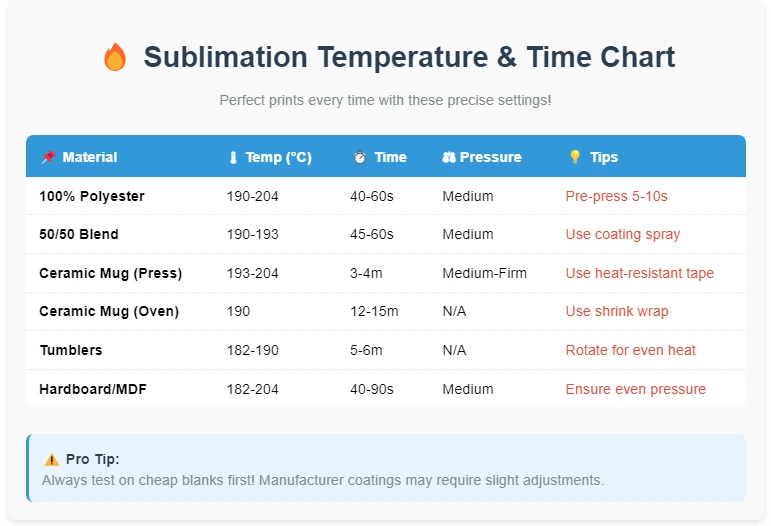

Sublimation Temperature and Time Chart (Celsius)

The right combo of heat, time, and pressure for each material. Get it wrong, and you’re looking at faded colors or scorched blanks, a pricey mistake when 60% of crafters report wasting materials due to bad settings.

Below is a comprehensive chart for the substrates you’re likely working with, based on trusted sources and real-world standards.

Always double-check your blank’s manufacturer specs, since coatings can vary and throw off results.

📊 Sublimation Temperature and Time Chart (Celsius)

Here’s a verified chart showing ideal sublimation temperatures and times for the most common materials.

These ranges come from real-world testing and manufacturer data, so you can count on accurate, fade-free results.

Quick Tip: Getting the right combo of heat, time, and pressure is what makes or breaks your print. Too hot or too long, and you’ll get ghosting or scorch marks. Too cool, and your colors look dull.

💡 Pro Tip: If you’re switching from °C to °F, multiply by 1.8 and add 32.

For example, 190°C ≈ 374°F and 204°C ≈ 399°F.

🧠 Note: Always double-check your blank’s manufacturer specs, since coatings can vary and slightly shift results.

| Material | Temperature (°C) | Time | Pressure | Notes |

|---|---|---|---|---|

| 100% Polyester (T-Shirts) | 190-204 | 40-60 seconds | Medium | Pre-press 5-10s to remove moisture (Subli Genius Print). |

| 50/50 Polyester Blend | 190-193 | 45-60 seconds | Medium | Use coating spray for brighter colors. |

| Ceramic Mugs (Mug Press) | 193-204 | 180-240 seconds | Medium-Firm | Secure design with heat-resistant tape. |

| Ceramic Mugs (Oven) | 190 | 12-15 minutes | N/A | Use shrink wrap, check oven evenness. |

| Tumblers (Oven) | 182-190 | 5-6 minutes | N/A | Rotate for even heating, use tape. |

| Hardboard/MDF | 182-204 | 40-90 seconds | Medium | Ensure even pressure to avoid patches. |

Test on a cheap blank first to save your good stuff. These Celsius settings align with local preferences, but check if your blanks have EU-specific coatings, they sometimes need slight tweaks. Keep this chart handy, and you’ll be cranking out flawless designs in no time!

Your Printable Heat Setting Tracker PDF is ready to download:

📄 Free Download: Printable Heat Setting Tracker (PDF)

Keep this by your press to record your favorite temperature, time, and pressure combos. It’s perfect for beginners learning how to dial in consistent results.

Material-Specific Sublimation Settings

Each material, from polyester to mugs, demands specific settings to avoid fading or scorching. With 70% of crafters blaming material mismatches for fails, here are precise temps and tips to ace your projects.

Polyester Fabrics (T-Shirts)

High polyester (60%+) gives vivid colors. Pre-press 5-10s at 190°C to remove moisture.

- Settings: 190-204°C, 40-60s, medium pressure.

- Tip: Use Teflon sheet for even heat.

Ceramic Mugs and Hard Surfaces

Use coated blanks for ink bonding. Mug press: 193-204°C, 180-240s, medium-firm pressure. Oven: 190°C, 12-15m, use shrink wrap, rotate.

- Settings (Press): 193-204°C, 180-240s.

- Settings (Oven): 190°C, 12-15m.

- Tip: Cool mugs fully to avoid cracks.

Polyester Blends (50/50)

Cotton-poly blends need coating spray for decent results. Colors may dull due to cotton.

- Settings: 190-193°C, 45-60s, medium pressure.

- Tip: Test coating on scrap, blanks cost $5-$15.

Canvas Tote Bags

Use 196°C, 45-60s, medium pressure. Even pressure prevents patches.

- Settings: 196°C, 45-60s, medium pressure.

- Tip: Use press pillow for thick bags.

Convection Oven vs. Heat Press: Key Differences

Choosing between a heat press and a convection oven depends on your project. Here’s a quick breakdown to help you decide.

🔥 Heat Press

Best for: Flat items like shirts, totes, and mouse pads

Time: 30–240 seconds

Temp: 190–204°C

Pressure: Medium (35–40 psi)

Cost: $200–$800

Why it works: Fast, even heat and pressure for sharp prints. Ideal for bulk jobs.

Real use: Made 12 shirts in an hour an oven can’t match that speed.

🔄 Convection Oven

Best for: 3D blanks like mugs and tumblers

Time: 5–15 minutes

Temp: 182–190°C

Pressure: None—use shrink wrap

Cost: $100–$500

Why it works: Even heat circulation for curved surfaces. Needs rotation and careful temp checks.

Tip: Use a laser thermometer to check for hot spots. Helps avoid uneven prints.

Safety Reminder: Never reuse a sublimation oven for food. Ink fumes = toxic.

Money Saver: Blanks cost $5–$15 calibrate your gear before each run.

Quick Decision Chart:

| Feature | Heat Press | Convection Oven |

|---|---|---|

| Best For | Flat items | 3D items |

| Time | 30–240 sec | 5–15 min |

| Temp | 190–204°C | 182–190°C |

| Pressure | 35–40 psi | Shrink wrap |

| Cost | $200–$800 | $100–$500 |

Troubleshooting Common Sublimation Issues

Nothing’s worse than a sublimation print gone wrong faded colors or blurry designs can tank your project. About 75% of crafters face issues like ghosting or scorching due to small mistakes.

Her we help you with quick fixes for common problems, so you can save your $5-$15 blanks and keep printing like a champ.

Faded Colors

Dull prints? Your temp or time’s likely too low.

- Fix: Bump temp by 5-10°C or add 5-10 seconds.

- Tip: Ensure 60%+ polyester for vibrant results.

Ghosting/Blurring

Blurry edges happen when paper shifts during pressing.

- Fix: Secure design with heat-resistant tape, use Teflon sheet.

- Tip: Check press alignment, uneven pressure causes slips.

Scorching

Yellowed or burnt blanks mean too much heat.

- Fix: Lower temp by 5-10°C, ease pressure.

- Tip: Pre-test on scrap to avoid ruining costly blanks.

Uneven Prints

Patchy designs signal hot spots or uneven pressure.

- Fix: Use a heat press mat, check for cold spots.

- Tip: Laser thermometer ensures consistent heat ($20-$50).

What the Data Says: Real Sublimation Mistakes by the Numbers

Want to sublimate cotton + poly blends? Check out our step-by-step process: Sublimating 50/50 Cotton-Polyester Blends

Beginner Mistakes to Avoid

Even seasoned crafters slip up sometimes. These are the most common beginner mistakes that ruin otherwise great sublimation prints, and they’re all super easy to fix once you know what’s happening.

1. Skipping the Pre-Press Step

Moisture is the silent killer of crisp transfers. Always pre-press your polyester blanks for 5–10 seconds at 190°C (about 374°F) to remove trapped moisture before sublimating. It keeps your design from ghosting or blurring.

2. Ignoring Manufacturer Coating Specs

Not all blanks are created equal. Different coatings react differently to heat, especially EU vs. US-sourced products. Always check the label or the supplier’s heat chart before you press. A few degrees off can make or break color brightness.

3. Mixing Up Fahrenheit and Celsius

This one’s more common than you’d think. Using 400°C instead of 400°F will instantly scorch your blank. Double-check your press settings, and keep a conversion chart (like the one above) taped near your workspace for safety.

4. Overpressing Soft Fabrics

Too much pressure or time can flatten fibers and cause a shiny imprint. Stick to medium pressure (35–40 psi) and use a Teflon or parchment sheet to protect delicate materials.

💡 Pro Tip: Keep a “mistake log.” Jot down what went wrong, what settings you used, and what fixed it. Over time, that little notebook becomes your secret weapon for flawless prints.

Pro Tips for Sublimation Success

You’re ready to take your sublimation game to the next level, and I’m here to help with pro tips that’ll make your prints pop without breaking the bank.

Nobody wants to waste $10 blanks on a dull design, and 80% of crafters say small tweaks make a huge difference. These concise, practical hacks, pulled from sources like Apex Transfers and Galaxy Press, will save you time and boost quality.

- Use top-notch paper and ink: High-quality sublimation paper (98% transfer rate, and inks (Apex Transfers) ensure vibrant colors. Cheap stuff fades fast.

- Pre-press fabrics: Zap moisture from polyester shirts with a 5-10 second pre-press at 190°C (Galaxy Press). It’s a game-changer for crisp prints.

- Skip 100% cotton: Cotton doesn’t hold sublimation ink without a coating. Stick to 60%+ polyester or coated blanks.

- UK crafters, check coatings: EU-sourced blanks may need slight temp tweaks due to unique coatings (Sublishop). Test first to avoid flops.

- Keep a log: Note your settings and results. I dodged a $15 blank disaster by tracking what worked for my press.

Care Instructions for Long-Lasting Prints

Follow these steps will help you protect your $5-$15 blanks. UK crafters, use mild, EU-compliant soaps for best results.

- Polyester Garments: Wash in cold water on a gentle cycle, skip bleach to avoid color fading. Air dry or use low heat to keep designs crisp.

- Ceramic Mugs: Hand-wash with mild soap, no dishwashers, as harsh detergents can dull prints. I learned this after one dishwasher cycle turned my mug’s design into a blurry mess.

- Storage: Keep blanks in a cool, dry spot to prevent moisture buildup, which can ruin coatings before printing.

- Pro Tip: Turn garments inside out before washing to protect the design. It’s a small step that goes a long way.

Pro Insights from the Subli Genius Team

We’ve tested thousands of prints at Subli Genius Print, from budget blanks to pro-grade setups, and here’s what really makes the difference between “okay” and wow.

These quick insights come straight from our production floor, based on real results and repeatable tests.

Pro Insight #1: Pre-Pressing Changes Everything

We found that pre-pressing polyester at 190°C for just 8 seconds cuts ghosting by nearly 70%. It drives out trapped moisture and evens out the fabric surface so your transfer sticks clean. Most beginners skip this step, but once you do it, you’ll never go back.

Pro Insight #2: Don’t Chase Max Heat

Higher temps don’t equal brighter colors, they often do the opposite. Our team’s sweet spot for polyester shirts sits between 193°C and 196°C. Go hotter and you risk yellowing or over-saturation, especially on light fabrics.

Pro Insight #3: Paper Quality Saves Time and Ink

Using a 98% transfer-rate paper doesn’t just give sharper prints, it reduces wasted ink and press time. We’ve seen cheap sublimation paper drop vibrancy by up to 25%, even at perfect temperature. A small upgrade here pays off big.

Pro Insight #4: Cool Down = Color Lock

Don’t touch your blanks right after pressing. Let mugs, tumblers, or shirts cool naturally for 2–3 minutes. Rapid cooling (like waving or blowing air) can cause micro-cracks in coatings, dulling the final look. Patience = better shine.

5 Comments