DTG Printing on Black Shirt: Get Bright, Lasting Colors

DTG printing works well on black shirts when a white underbase layer is applied. This base makes colors look bright and sharp on dark fabric.

The process supports detailed designs, gradients, and full-color prints. For the best results, use 100% cotton shirts and pre-treat the fabric. This ensures long-lasting, vibrant prints that resist fading.

What is DTG Printing?

DTG printing is a highly effective technique that enables the direct printing of full-color designs onto fabric, utilizing specialized inkjet printers. It allows for printing photorealistic designs in vibrant colors on fabrics like cotton, polyester, and blended fabrics. But is DTG printing suitable for black shirts? Here are some key points to consider:

Is it good for DTG printing on a black shirt?

Yes, DTG printing works on black shirts when a white underbase is applied. This base allows colors to stay vibrant and detailed on dark fabric.

Prints may have slightly less durability compared to light garments, but with the right pre-treatment and bold designs, DTG delivers high-quality results on black shirts.

Light Ink Colors on Dark Fabrics

One of the main challenges with printing on black shirts is that lighter colors, like yellow, light pink, light blue, etc., do not appear well on dark fabric. DTG uses CMYK ink colors, so reproducing vivid bright colors on black can be difficult. The white ink in DTG printers helps but has limitations.

White Ink Layer

Many DTG printers have a white ink cartridge that lays down a layer of white before the colors. This acts as a “base,” so the colors on top will pop. However, white ink tends to be more opaque rather than bright white. So the colors on top will be muted and dull instead of vivid.

Test Prints Are Essential

It’s important to test print designs before printing a batch of black shirts. Check how the colors look when printed. Light pastel colors may not work well. Go for bright, bold designs instead. Verify the white ink under the base gives enough brightness. Adjust colors and use dark shades for a better visual effect.

Pretreatment is Key

DTG printing requires pre-treating fabric with a solution before printing. For black shirts, use a higher concentration or double-coat the pretreatment solution. This allows the white ink to bond better with the fabric. Proper pretreatment can improve print quality, washed-out colors, and cracking.

Post-Print Heat Pressing

After DTG printing, heat press the garment for 30-60 seconds to cure inks. Use a slightly higher temperature for black shirts and press a few seconds longer. This ensures inks are fully bonded to the fabric. Check manufacturer guidelines for temps and times.

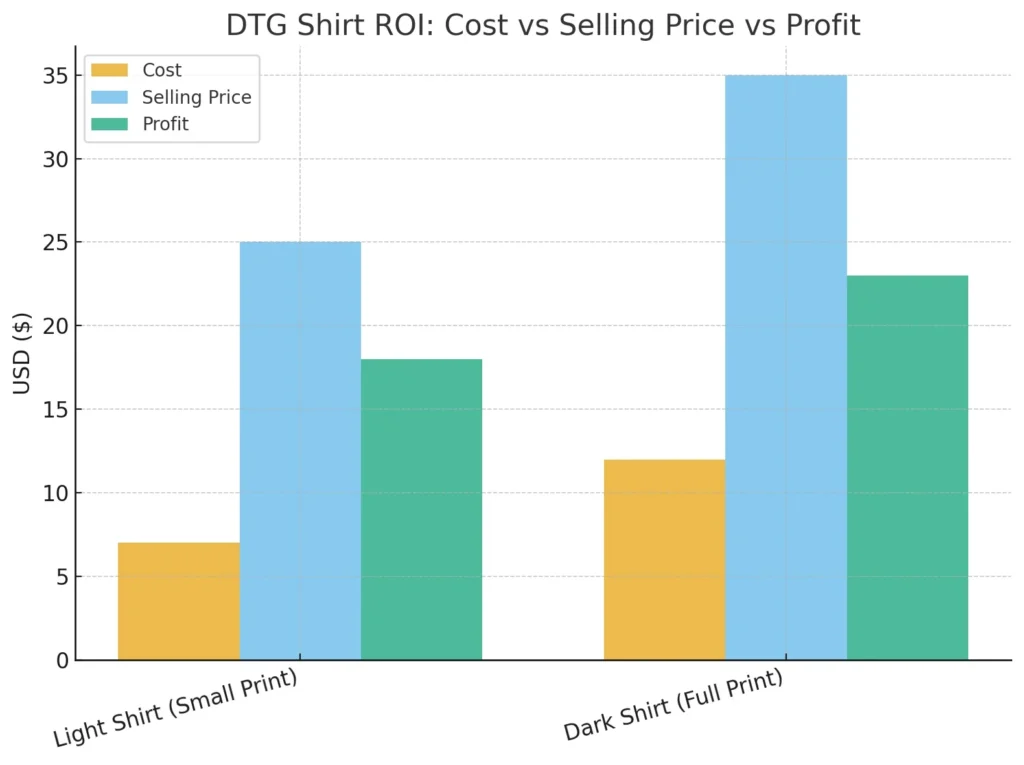

How Much Does It Cost to Print a DTG Shirt

The cost to print a DTG shirt usually ranges from $5 to $15 per shirt, depending on factors like shirt quality, ink coverage, and order size. Basic cotton shirts with small designs cost less, while full-color prints on premium garments cost more. Selling prices often range between $20 and $40, leaving room for profit.

- Blank Shirt

- Standard cotton shirt: $2 – $5

- Premium brand or fashion-fit: $6 – $10

- Ink Cost

- Light shirt print (less ink): $0.50 – $1.50

- Dark shirt with white underbase: $2 – $3.50

- Pre-Treatment (for dark shirts)

- Average cost per shirt: $0.25 – $0.50

- Labor

- Loading, printing, pressing: $1 – $3 depending on shop rate

- Overhead

- Power, equipment wear, shop expenses: $0.50 – $1

Average Cost Per Shirt

- Light shirt, small print: $5 – $8

- Dark shirt, full-color design: $8 – $15

Retail Pricing

Most DTG shirts sell between $20 – $40, giving a solid profit margin.

Pros and Cons of DTG on Black Shirts

Pros:

- Can achieve photorealistic, full-color prints

- No minimum orders required

- Lower setup costs compared to screen printing

Cons:

- Difficulty achieving bright colors on black fabric

- More pretreatment steps involved

- White ink has opacity limitations

- Higher risk of print defects or cracking

Best Practices for DTG on Black

- Test and adjust colors to use bold, dark shades

- Use appropriate pretreatment and heat press settings

- Inspect prints for defects before fulfilling orders

- Use higher quality blank black shirts

- Set customer expectations for color limitations

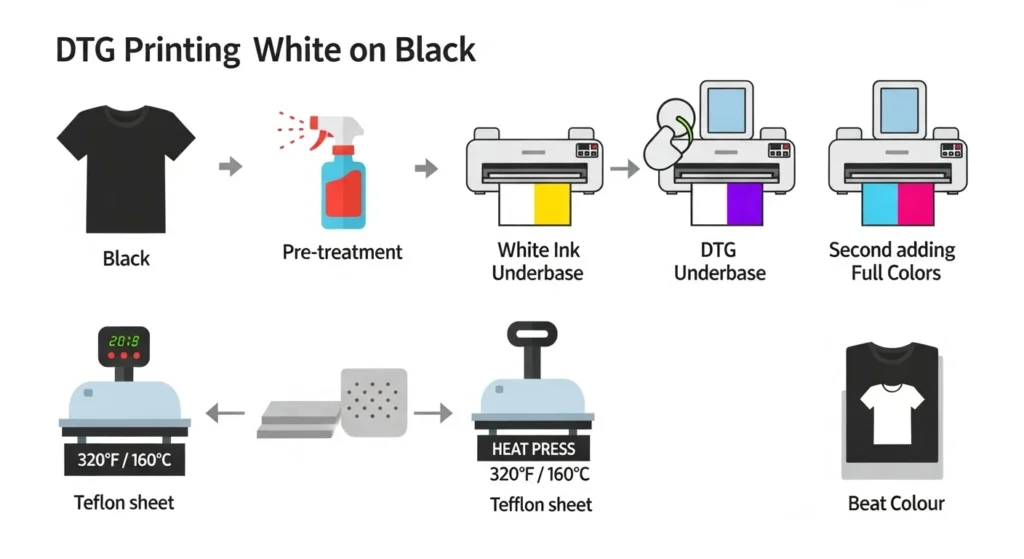

How to Print White on a Black Shirt

Printing white on a black shirt with DTG requires a strong white ink underbase. First, pre-treat the shirt so the ink bonds well with the fabric.

Then, use a DTG printer loaded with white ink to lay down the base layer. This step makes the design crisp and visible on dark fabric. A final heat press locks the print in place.

Step-by-Step Checklist for Printing White on a Black Shirt

- Choose the right shirt – Use 100% cotton for the best print quality.

- Pre-treat the fabric – Spray evenly with pre-treatment solution and dry it.

- Load the shirt – Place it flat on the DTG printer platen with no wrinkles.

- Print the white base – Use white ink as the underlayer for your design.

- Add color layers – Print the rest of the design over the white base.

- Prepare the heat press – Set temperature to 320°F (160°C).

- Cover the print – Use Teflon sheet or parchment paper to protect it.

- Press the shirt – Apply medium pressure for 90–120 seconds.

- Check the cure – The print should feel dry, not sticky.

- Final wash test – Wash inside out in cold water to confirm durability.

DTG Heat Press Settings

Proper heat press settings are key for lasting prints. For most DTG shirts, press at 320°F (160°C) for 90–120 seconds with medium pressure.

Always use a Teflon sheet or parchment paper on top to protect the design. These settings ensure the ink cures fully, preventing fading and cracking after washes.

How long do DTG printing on a black shirt last?

- Most DTG printer manufacturers cite 10-15 washes as the average print lifespan under proper care and curing. Independent print shops report similar longevity findings.

- Achieving 50+ wash durability for DTG is uncommon and would require exceptionally high-quality pretreatment, inks, printer maintenance, and perfect curing/heating settings – difficult to achieve consistently.

- For high-volume wholesale screenprinting, 50+ washes may be expected. But DTG is geared more towards lower-volume, customizable printing where customers likely don’t expect such long print lives.

- While DTG prints may survive 50+ washes before complete deterioration, print quality degradation like fading and cracking would likely occur much earlier, as standard wash test results indicate.

- “Good enough” print quality for most DTG customers may mean acceptable results for 10-20 washes, not necessarily 50+.

Explore the world of sublimation and printers with our comprehensive guide for more information or a step-by-step how-to guide.

3 Comments