The Role of Artificial Intelligence in Modern Print Production

Artificial intelligence is transforming modern print production by automating workflows, improving accuracy, and reducing operational costs. AI tools help printers predict maintenance needs, optimize color and layout, speed up job processing, and cut manual steps.

These technologies make printing more efficient, reliable, and adaptable to today’s fast-moving production demands.

If you’re new to digital production methods, this guide explains what sublimation printing is in a simple, practical way.

Why AI Matters in Print Production

AI is transforming print production by helping printers work faster, more accurately and with less waste. As demand grows for personalised and on-demand printing, traditional workflows struggle. AI bridges the gap by analysing data, automating routine steps and improving decisions in real time.

Printers now use AI for scheduling, colour control and equipment reliability. The result is smoother workflows, fewer errors and stronger competitiveness. AI is becoming essential for any print operation aiming to stay efficient and relevant in a rapidly changing industry.

To understand where AI fits into each production stage, you can review the full sublimation printing process for a clear workflow overview.

How AI Is Applied Across Print Workflows

AI streamlines print production by automating tasks that slow teams down. It improves accuracy, reduces waste and keeps machines running smoothly.

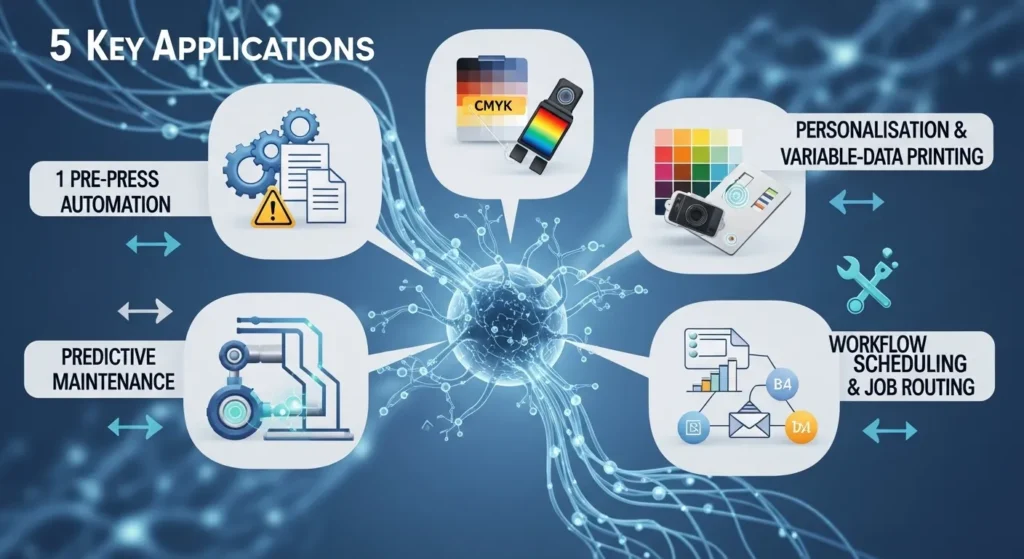

1. Pre-Press Automation

AI speeds up file preparation by:

- Detecting layout or font errors automatically

- Cleaning images, fixing resolution issues

- Suggesting optimal imposition to cut waste

Impact: Up to 40% faster pre-press turnaround in busy shops.

2. Colour Management

AI maintains consistent colour across presses by:

- Reading print data in real time

- Adjusting profiles automatically

- Reducing colour drift on long runs

Benefit: Fewer reprints and more predictable results.

3. Predictive Maintenance

Sensors track press performance and alert teams before breakdowns happen.

- Monitors heat, vibration and wear

- Predicts part failures

- Cuts unplanned downtime

Outcome: Shops can reduce machine downtime by 20–30%.

4. Workflow Scheduling & Job Routing

AI helps manage heavy workloads by:

- Sorting incoming jobs

- Assigning the best press

- Estimating completion times

Result: Balanced workloads and fewer production bottlenecks.

5. Personalisation & Variable-Data Printing

AI makes large-scale customisation possible.

- Creates targeted labels, packaging or marketing pieces

- Uses customer data for personalised content

- Improves campaign relevance and ROI

Advantage: Faster and more affordable personalisation at scale.

This video, Webinar | Discover How AI Is Reshaping Production Printing, explores how AI is enabling organizations to streamline processes and create sustainable print practices.

Real-World Benefits: What Print Businesses Gain

AI delivers practical, measurable improvements across print operations. The biggest gains come from speed, accuracy and lower production costs.

1. Faster Turnaround Times

AI reduces manual steps throughout the workflow.

- Automates pre-press checks

- Optimises scheduling and routing

- Speeds up approval and setup

Impact: Jobs can move 25–50% faster from file submission to final print.

2. Lower Costs & Less Waste

AI cuts waste by predicting errors before they occur.

- Smarter imposition = fewer sheets used

- Better colour control = fewer reprints

- Predictive maintenance = fewer breakdowns

Savings: Many printers see 10–20% lower material waste.

3. More Consistent Quality

AI maintains high standards even on long runs.

- Real-time colour adjustments

- Automated defect detection

- Stable print conditions across machines

Benefit: Higher customer satisfaction and fewer returns.

4. Stronger Customer Experience

AI enables personalised, on-demand printing.

- Custom packaging and labels

- Targeted marketing materials

- Fast reorders and real-time job tracking

Result: Customers get exactly what they want, faster and with better accuracy.

5. New Revenue Opportunities

AI creates space for premium services.

- Generative design support

- Data-driven variable-data printing

- Interactive print experiences with AR and smart tags

Advantage: Print shops can differentiate and upsell new offerings.

Implementation Challenges and What to Watch Out For

AI brings big advantages, but print shops often face hurdles when trying to integrate new technology. Understanding these challenges early helps avoid costly mistakes.

1. Data Quality & System Integration

AI only works well when data is accurate and consistent.

Common issues include:

- Incomplete job data or inconsistent file naming

- Legacy MIS or RIP systems that don’t connect smoothly

- Press data that isn’t captured in real time

Risk: Poor data leads to unreliable AI decisions.

2. Skills Gap & Training Needs

Teams may be unfamiliar with AI tools.

- Operators need training in new software

- Managers must understand AI dashboards

- IT support may need upgrading

Impact: Without training, AI tools remain underused.

3. Upfront Costs vs Long-Term ROI

AI automation often requires investment.

- Hardware upgrades

- Software subscriptions

- Staff training or workflow redesign

Consideration: ROI usually appears within 12–36 months, depending on the shop’s volume and complexity.

4. Change Management Resistance

Employees may worry about job changes or new responsibilities.

- Fear of automation replacing roles

- Hesitation to trust AI decisions

- Difficulty shifting from manual to digital workflows

Solution: Clear communication and phased rollouts reduce resistance.

5. Ethical, Security & Compliance Factors

AI relies on customer data, especially for personalisation.

Concerns include:

- Protecting sensitive customer information

- Meeting GDPR or regional privacy requirements

- Ensuring transparency in automated decisions

Need: Strong data policies and secure systems.

Many of the issues AI helps reduce are outlined in this guide to common sublimation printing problems solved.

The Future of Print: AI, Augmented Reality and Beyond

AI is reshaping how print is produced, sold and experienced. The next phase blends automation, smart data and interactive technologies that make print more connected and more valuable.

GenAI shifts the designer’s role from manual execution to strategic direction.

“The next five years won’t be about AI replacing the designer; it will be about the designer who uses Generative AI replacing the one who doesn’t.”

1. Generative AI + Print

Generative tools will become standard in design and pre-press.

- Auto-creates layouts, colour palettes and product mockups

- Speeds up creative workflows

- Helps teams test multiple versions instantly

Benefit: Designers gain time, and customers get faster proofs.

2. Augmented Reality (AR) and Interactive Print

Printed pieces will increasingly link to digital experiences.

- AR labels and packaging

- Scannable brochures, magazines and signage

- Smart tags with trackable engagement data

Impact: Print becomes measurable, interactive and integrated with online marketing.

3. Smarter Presses and Full Automation

AI-driven presses will operate with minimal manual adjustments.

- Self-correcting colour

- Automated calibration

- AI-based ink and substrate optimisation

Trend: More shops will run near-lights-out production for long jobs.

4. AI in Publishing & Content Personalisation

Publishers will use AI to create tailored content at scale.

- Personalised newspapers or magazines

- Dynamic book covers and targeted inserts

- Better editorial planning with audience data

Result: More relevant content and improved reader engagement.

5. Business Model Shifts

AI will push print companies to adopt hybrid strategies.

- On-demand printing

- Micro-runs with variable data

- Subscription-based production workflows

Advantage: Higher margins and lower storage costs.

6. What Print Firms Should Do Now

To stay ahead, companies should:

- Audit current workflows for automation gaps

- Collect and clean production data

- Test small AI tools before large investments

- Train teams early to reduce resistance

- Build partnerships with tech vendors

If you want a broader look at print efficiency, this article covers the benefits of sublimation printing and why it remains a popular production method.

AI Roadmap Adoption: Leaders vs. Laggards

Percentage of companies with a clear AI implementation roadmap.

Data Snapshot — AI in Print (Illustrative)

Risk Assessment: AI’s Hidden Costs & Challenges (Concise)

While AI promises efficiency, implementing it successfully involves anticipating specific, hidden friction points. Addressing these challenges upfront is crucial for avoiding budget overruns and project delays.

1. The Data Quality Hurdle

AI models are highly dependent on the quality of their training data.

- Challenge: Decades of legacy print data (job tickets, ICC profiles, error logs) are often inconsistent and messy. Feeding this “garbage” to the AI leads to automated errors, not efficiency.

- Hidden Cost: Significant time and budget must be allocated to data cleaning, standardization, and tagging before the AI system can deliver accurate, reliable results.

2. Integration & Infrastructure Barriers

Connecting new AI solutions to your existing ecosystem is rarely seamless.

- Legacy Systems: Older MIS and ERP systems often lack the necessary modern APIs (application programming interfaces). This requires costly custom middleware development or expensive upgrades to enable data exchange with new AI modules.

- IoT Cost: For predictive maintenance, the main expense isn’t just the software; it’s the purchase and installation of Industrial IoT sensors across your presses, plus the network infrastructure needed to handle constant data streaming.

3. The Organizational Skills Gap

AI changes job roles, requiring new expertise that often doesn’t exist in-house.

- Training Demands: Operators and managers need extensive training to effectively interpret, manage, and trust AI outputs. Budgeting for specialized training programs and employee time-off is mandatory.

- Oversight Needed: You need staff capable of monitoring the AI models themselves (identifying model “drift”) and performing necessary recalibration and maintenance, requiring a rare hybrid IT/production skillset.

🧠 AI Readiness Checklist

-

✓

**Data:** Is your core production data clean, tagged, and centralized?

-

✓

**Systems:** Have you budgeted for custom development or upgrades to ensure API compatibility?

-

✓

**Talent:** Is there a clear, funded plan for upskilling staff to manage and interpret AI outputs?

Assess your readiness before diving into AI implementation.

Case Studies and Success Stories

Real examples show how AI is already transforming print operations. These cases highlight measurable gains in speed, quality and cost efficiency.

Case Study 1: Commercial Print Shop Boosts Output

A mid-sized commercial printer integrated AI-driven scheduling and colour management software.

Results:

- 30% faster job turnaround

- 18% reduction in material waste

- Fewer colour corrections and reprints

Takeaway: AI made production more predictable during peak workloads.

Case Study 2: Packaging Printer Improves Colour Consistency

A packaging company used AI sensors to monitor colour in real time.

Results:

- Colour variation dropped by 40%

- Press operators spent less time adjusting ink

- Customer complaints decreased noticeably

AI stabilised quality on long, complex print runs.

Case Study 3: Digital Print Shop Adopts Predictive Maintenance

A high-volume digital press facility added AI-based monitoring tools.

Results:

- 25% fewer equipment breakdowns

- Machine uptime increased

- Maintenance costs became easier to forecast

Predictive maintenance protected productivity and reduced unplanned stoppages.

Case Study 4: Publishing Company Personalises Content

A magazine publisher used AI to tailor covers and article layouts for reader segments.

Results:

- Engagement increased by 22%

- More targeted ad placements

- Faster issue planning

AI created content that felt more relevant and commercially valuable.

Case Study 5: Label Printer Scales Variable-Data Printing

A label manufacturer integrated AI-powered VDP tools.

Results:

- Custom label output increased by 50%

- Setup time dropped from hours to minutes

- Improved accuracy in serialised and versioned designs

AI made large-scale personalisation efficient and profitable.

For long-term trends shaping the industry, this overview of the future of sublimation shows how new technologies are influencing print production.

Practical Guide: Getting Started With AI in Your Print Operation

AI adoption works best when print shops start small, focus on real bottlenecks and build confidence with quick wins. This guide helps you plan a smooth, low-risk transition into AI-powered production.

1. Assess Your Current Workflow

Identify where delays, errors or manual tasks slow your team down.

Look closely at:

- Pre-press checks

- Colour adjustments

- Job scheduling

- Machine downtime

Goal: Find areas where AI can make an immediate impact.

2. Collect and Clean Your Data

AI relies on accurate information.

Start by improving:

- File naming consistency

- Job ticket details

- Press performance logs

- Colour and waste records

Tip: Even a 10–15% improvement in data accuracy boosts AI results significantly.

3. Start With Small, Low-Risk AI Tools

Begin with tools that require minimal disruption.

Easy starters include:

- AI pre-flight and file inspection

- Colour management automation

- Job-routing recommendations

- Predictive maintenance sensors

Outcome: Quick wins build team confidence and justify further investment.

4. Choose the Right Vendors or Platforms

When comparing AI solutions, look for:

- Compatibility with your RIP, MIS or workflow software

- Clear training and onboarding support

- Transparent pricing

- Real case studies, not just marketing claims

Smart move: Request a 30–60 day pilot before committing.

5. Train Teams Early

AI works best when operators understand how to use it.

- Offer simple tutorials and walkthroughs

- Explain how AI supports jobs, not replaces them

- Encourage operators to share feedback and improvements

Benefit: Smoother adoption and fewer errors.

6. Track Results and Scale Up

Monitor key metrics as you expand AI usage:

- Turnaround time

- Colour consistency

- Waste percentage

- Machine uptime

Goal: Use real numbers to shape your long-term roadmap.

7. Build Toward Full Workflow Automation

Once the basics are in place, move toward:

- Automated scheduling

- Lights-out production for long runs

- Real-time quality checks

- AI-triggered maintenance

Future-proofing: This creates a stable, scalable and highly efficient print operation.

If you want to explore advanced methods that pair well with automated workflows, this guide on sublimation techniques breaks down practical ways to improve print results.