7 Amazing Sublimation Techniques You Need to Try

I used to think sublimation was just press and done, until one small experiment completely changed how my designs looked. That moment made me curious about how a few simple techniques can turn ordinary prints into products people actually notice.

Sublimation is a digital printing process that uses heat and pressure to transfer dye onto different materials, such as fabric, metal, ceramic, or wood.

Sublimation Techniques Comparison

| Sublimation Technique | Best For | Difficulty Level | Works Best On |

|---|---|---|---|

| Layering Sublimation | Depth, multi-color designs, stacked effects | Medium | Polyester shirts, coated hard blanks |

| Distressed Sublimation | Vintage, rustic, handmade looks | Easy | Mugs, signs, fabric, decor items |

| Glitter Sublimation | Eye-catching accents and bold highlights | Medium | Metal signs, ornaments, apparel |

| Watercolor Sublimation | Soft, artistic, painter-style designs | Medium | Canvas, fabric panels, wall art |

| Marble Sublimation | Elegant, high-end stone effects | Medium | Coasters, tiles, plaques |

| Tie-Dye Sublimation | Fun, colorful, handmade aesthetics | Easy | T-shirts, pillowcases, totes |

| Foil Sublimation | Premium metallic finishes | Advanced | Notebooks, signage, gift items |

7 Amazing Sublimation Techniques

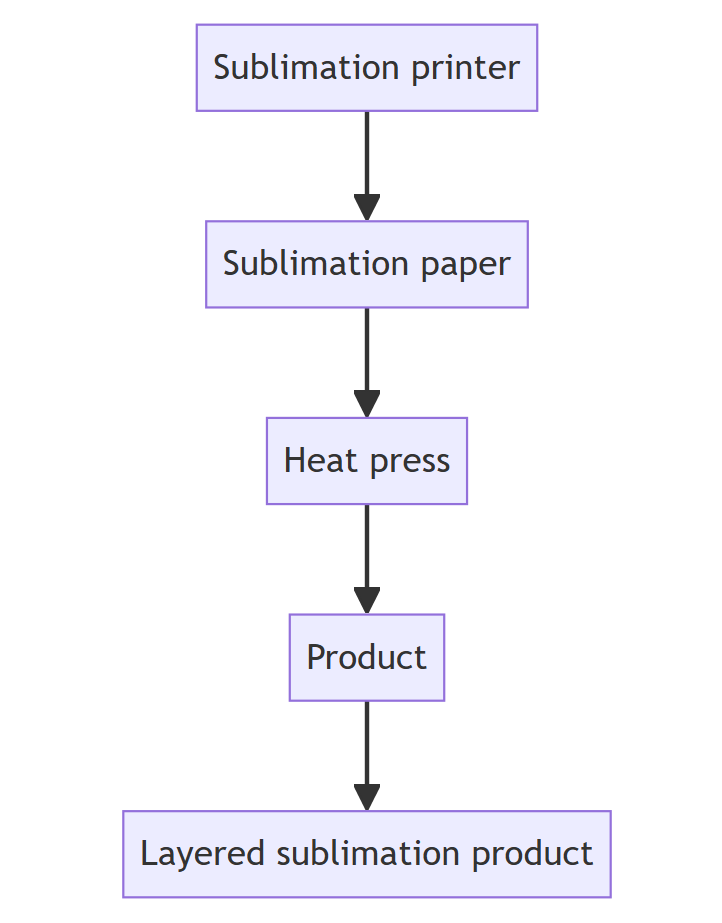

1. Layering Sublimation

Layering sublimation lets you combine two or more designs on the same product to create depth, color variation, or a stacked visual effect. It’s especially useful when you want details to stand out without overcrowding a single print.

This technique works best on polyester fabrics and hard blanks that can handle multiple heat presses.

What You’ll Need

- Sublimation printer

- Sublimation ink

- Sublimation paper

- Heat press

- Heat-resistant tape

- Protective sheet, parchment paper or Teflon

- A sublimation-ready product, like a polyester t-shirt or coated hard blank

You can check 5 Sublimation Techniques That Instantly Improve Print Quality

How Layering Sublimation Works

Instead of pressing everything at once, you print each design element separately and press them one at a time. Each layer bonds into the surface, creating a blended or stacked effect rather than a flat image.

Step-by-Step Instructions

- Print each design layer separately using sublimation ink. Mirror every design before printing.

- Trim each print, leaving a small margin around the artwork.

- Pre-press the product for a few seconds to remove moisture and wrinkles.

- Place the first design on the product, secure it with heat-resistant tape, and cover it with a protective sheet.

- Press using the recommended temperature and time for your material.

- Carefully remove the paper and let the product cool slightly.

- Align the next design layer, secure it, and press again using the same settings.

- Repeat until all layers are applied, then allow the product to cool completely.

Best Uses for Layering Sublimation

- Multi-color logos

- Text layered over patterns

- Accent graphics or highlights

- Designs that need visual depth without heavy ink coverage

Pro Tips for Clean Results

- Keep each layer light to avoid over-saturation

- Allow brief cooling between presses to prevent ghosting

- Avoid placing dark layers over fully saturated areas

- Test layering order on scrap material first

Layering sublimation takes a little more patience, but the results feel intentional and premium when done right.

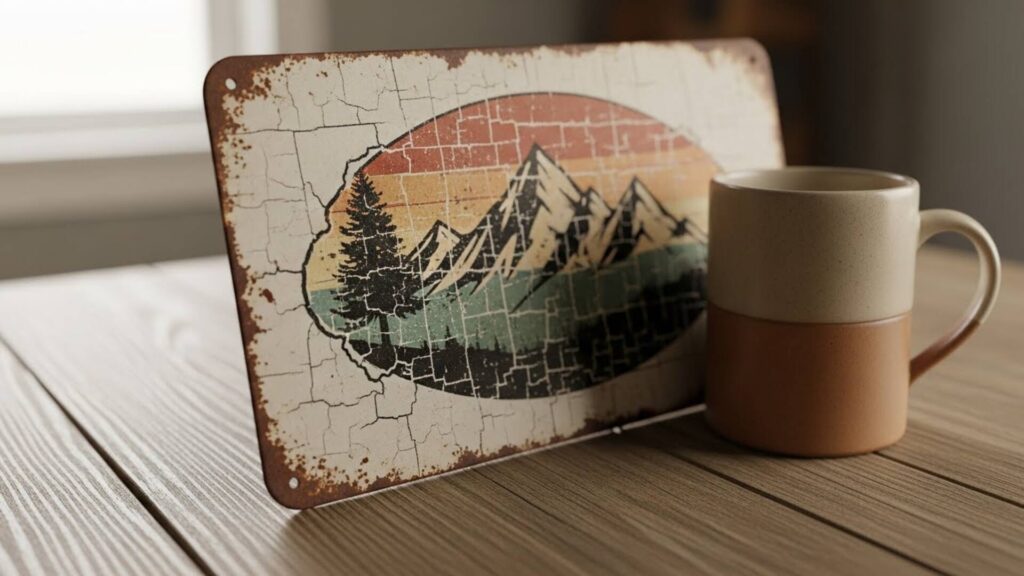

2. Distressed Sublimation

Distressed sublimation is all about making a design feel worn-in, imperfect, and real. Instead of a smooth, flawless print, you get texture, faded edges, and a vintage look that works great for rustic, retro, or handmade-style products.

This technique is popular for mugs, signs, and apparel where “too perfect” actually looks wrong.

What You’ll Need

- Sublimation printer

- Sublimation ink

- Sublimation paper

- Heat press

- Heat-resistant tape

- Protective sheet, parchment paper or Teflon

- A sublimation-ready product, like a ceramic mug or polyester fabric

If you want a deeper understanding of paper behavior and how it affects texture, this guide on sublimation paper explains why some papers distress better than others.

How Distressed Sublimation Works

The distressed effect comes from interrupting perfect ink transfer. By crumpling, folding, or lightly wrinkling the sublimation paper, parts of the design transfer unevenly, creating natural-looking breaks and texture.

No two results look the same, which is part of the charm.

Step-by-Step Instructions

- Print your design using sublimation ink and mirror the image before printing.

- Cut out the design, leaving a small margin around the edges.

- Gently crumple or wrinkle the sublimation paper, then flatten it slightly. Don’t over-crush it.

- Pre-press your product for a few seconds to remove moisture.

- Wrap or place the textured paper onto the product and secure it with heat-resistant tape.

- Cover with a protective sheet and press using the recommended time and temperature for your material.

- Remove the paper carefully and allow the product to cool completely.

Best Uses for Distressed Sublimation

- Vintage-style graphics

- Farmhouse or rustic signs

- Retro typography

- Handmade or craft-inspired designs

Pro Tips for Natural Results

- Light designs distress better than heavy solid fills

- Avoid fine text, it can become unreadable

- Test different crumple levels to control how rough the effect looks

- Use this technique intentionally, not on every design

Distressed sublimation works best when the imperfections feel planned, not accidental.

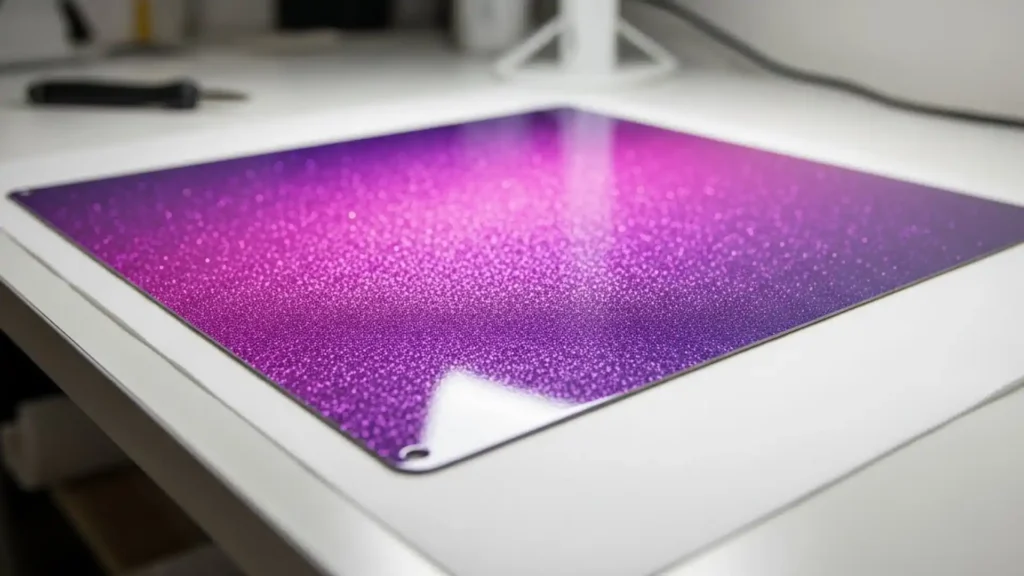

3. Glitter Sublimation

Glitter sublimation is perfect when you want a design to pop without going over the top. It adds shimmer and depth while keeping the print smooth, not rough or flaky like traditional glitter vinyl. When done right, it looks clean, bright, and premium.

This technique works especially well for signs, ornaments, phone cases, and statement apparel.

What You’ll Need

- Sublimation printer

- Sublimation ink

- Glitter sublimation paper or glitter sublimation vinyl

- Heat press

- Heat-resistant tape

- Protective sheet, parchment paper or Teflon

- A sublimation-ready product, like a metal sign or polyester fabric

If colors ever look dull or muddy with glitter surfaces, this breakdown on why sublimation colors look dull and how to fix it helps you dial things in before pressing.

How Glitter Sublimation Works

Instead of absorbing ink like fabric, the glitter coating reflects light through the transferred dye. That reflection creates sparkle while still allowing full-color designs to show through.

The key is even pressure and proper temperature, otherwise the shimmer can look patchy.

Step-by-Step Instructions

- Print your design using sublimation ink and mirror the image before printing.

- Cut the design with a small margin around the edges.

- Pre-press the product briefly to remove moisture and wrinkles.

- Place the glitter sublimation paper or vinyl onto the product and secure it with heat-resistant tape.

- Cover with a protective sheet and press using the recommended temperature and time for the glitter material.

- Remove the paper or vinyl carefully and allow the product to cool fully before handling.

Best Uses for Glitter Sublimation

- Name designs and monograms

- Decorative signs and plaques

- Holiday ornaments

- Accent graphics that need visual punch

Pro Tips for a Clean Sparkle

- Avoid ultra-fine text, glitter needs breathing room

- Medium to bold designs show sparkle best

- Don’t over-press, too much heat can mute the shine

- Always test on scrap glitter material first

Glitter sublimation works best as an accent, not the whole design. A little shimmer goes a long way.

4. Watercolor Sublimation

Watercolor sublimation is all about softness. Instead of sharp edges and solid fills, this technique creates washed-out areas, gentle blends, and an artsy, hand-painted feel. It’s a great choice when you want designs to look calm, creative, and less digital.

This style works beautifully on canvas, fabric panels, wall art, and decor pieces where texture actually adds value.

What You’ll Need

- Sublimation printer

- Sublimation ink

- Sublimation paper

- Heat press

- Heat-resistant tape

- Protective sheet, parchment paper or Teflon

- A sublimation-ready product, like canvas or polyester fabric

- Clean water and a soft watercolor brush

If you’re working with fabric or canvas and want better results, this guide on best fabrics for sublimation helps you avoid materials that fight the watercolor effect.

How Watercolor Sublimation Works

The design is sublimated first like normal. After pressing, water is introduced to soften edges, lighten ink density, and create natural bleed patterns. The ink doesn’t run, but it visually loosens, giving that painted look.

You’re not washing the design away. You’re reshaping how it feels.

Step-by-Step Instructions

- Print your design using sublimation ink and mirror the image before printing.

- Cut out the design, leaving a small margin around the edges.

- Pre-press the product briefly to remove moisture and wrinkles.

- Place the sublimation paper on the product, secure it with heat-resistant tape, and cover it with a protective sheet.

- Press using the recommended time and temperature for your material.

- Remove the paper and allow the product to cool completely.

- Lightly dampen a watercolor brush with clean water and gently brush over areas where you want a faded or blended effect.

- Let the product dry fully before handling or displaying.

Best Uses for Watercolor Sublimation

- Floral and botanical designs

- Abstract art and soft landscapes

- Nursery or home decor prints

- Minimalist or calming visuals

Pro Tips for Soft, Natural Results

- Start with less water, you can always add more

- Light-colored designs respond better than dark, heavy fills

- Avoid fine text, watercolor effects can blur readability

- Test brush pressure on scrap material first

Watercolor sublimation shines when you let go of perfection and let the texture do the talking.

5. Marble Sublimation

Marble sublimation gives designs a polished, high-end look that feels closer to stone art than standard printing. The veining and soft color movement create a natural pattern, so every piece comes out slightly different, which makes the final product feel premium and custom.

This technique works especially well for coasters, plaques, ornaments, and decor items where elegance matters.

What You’ll Need

- Sublimation printer

- Sublimation ink

- Sublimation paper

- Heat press

- Heat-resistant tape

- Protective sheet, parchment paper or Teflon

- Marble-effect sublimation paper or marble spray

- A sublimation-ready product, like a coated coaster or stone-style blank

If you’re unsure which blanks handle this technique best, this guide on sublimation blanks and substrates helps you avoid surfaces that won’t hold the effect properly.

How Marble Sublimation Works

The marble look comes from controlled randomness. Either the sublimation paper already contains a marble pattern, or a marble spray is applied after pressing to create natural-looking veins and movement.

The design stays sharp, but the background gains depth and texture.

Step-by-Step Instructions

- Print your design using sublimation ink and mirror the image before printing.

- Trim the design, leaving a small margin around the edges.

- Pre-press the product briefly to remove moisture.

- Place the marble sublimation paper on the product, secure it with heat-resistant tape, and cover with a protective sheet.

- Press using the recommended temperature and time for your blank.

- Remove the paper carefully and allow the product to cool completely.

Optional marble spray finish:

7. Lightly apply marble spray to the cooled surface, following the manufacturer’s instructions.

8. Allow the product to dry fully before handling or packaging.

Best Uses for Marble Sublimation

- Coasters and tile decor

- Home accents and wall art

- Memorial or keepsake items

- Minimalist logos and text designs

Pro Tips for a Natural Stone Look

- Simple designs work better than busy graphics

- Use neutral or muted colors for realistic marble effects

- Don’t overspray, subtle veining looks more convincing

- Always test spray distance on a scrap blank

Marble sublimation shines when the design supports the texture, not competes with it.

6. Tie-Dye Sublimation

Tie-dye sublimation brings color, movement, and a handmade vibe into your designs. Instead of sharp edges or flat backgrounds, you get flowing patterns that feel playful and unique. No two pieces ever look the same, which is exactly why people love this style.

It’s a great fit for apparel, pillowcases, tote bags, and casual decor where bold color actually sells.

What You’ll Need

- Sublimation printer

- Sublimation ink

- Sublimation paper

- Heat press

- Heat-resistant tape

- Protective sheet, parchment paper or Teflon

- Tie-dye sublimation paper or a tie-dye kit

- A sublimation-ready product, like a polyester shirt or pillowcase

If you’re working with blended fabrics and want to avoid dull results, this guide on sublimating 50/50 cotton polyester blends explains what to expect before you press.

How Tie-Dye Sublimation Works

The base design is sublimated first. After that, color is introduced using either tie-dye sublimation paper or a traditional tie-dye method. The dye adds movement and contrast while the sublimated design stays locked into the surface.

You’re combining structure with chaos, and that balance is what makes it work.

Step-by-Step Instructions

- Print your design using sublimation ink and mirror the image before printing.

- Cut the design, leaving a small margin around the edges.

- Pre-press the product briefly to remove moisture and wrinkles.

- Place the sublimation paper on the product, secure it with heat-resistant tape, and cover it with a protective sheet.

- Press using the recommended time and temperature for your material.

- Remove the paper and allow the product to cool completely.

Optional tie-dye finish:

7. Apply the tie-dye kit following the package instructions, using folds or patterns to control color flow.

8. Let the product dry fully before washing or using.

Best Uses for Tie-Dye Sublimation

- Casual t-shirts and hoodies

- Pillowcases and fabric decor

- Youth and summer-themed designs

- Bold typography or simple graphics

Pro Tips for Bold, Clean Results

- Simple designs stand out better than detailed artwork

- Leave negative space so colors can breathe

- Test dye saturation before committing to final pieces

- Wash gently after curing to preserve vibrancy

Tie-dye sublimation works best when the color does part of the storytelling.

7. Foil Sublimation

Foil sublimation adds a sleek, metallic finish that instantly makes a product feel premium. Instead of a flat print, you get reflective highlights that catch the light and draw attention. It’s perfect when you want designs to feel upscale without turning flashy.

This technique works great for notebooks, plaques, signage, and accent details where shine is meant to stand out.

What You’ll Need

- Sublimation printer

- Sublimation ink

- Sublimation paper

- Foil sublimation paper or foil transfer sheet

- Heat press

- Heat-resistant tape

- Protective sheet, parchment paper or Teflon

- A sublimation-ready product, like a notebook cover or coated hard blank

If foil transfers aren’t sticking cleanly, this guide on heat press sublimation settings helps dial in pressure and timing so the foil bonds evenly.

How Foil Sublimation Works

The design is sublimated first, then foil is applied in a second press. The foil adheres only to areas where the ink or adhesive activates it, creating crisp metallic highlights without covering the entire surface.

It’s a two-step process, but the results look polished and intentional.

Step-by-Step Instructions

- Print your design using sublimation ink and mirror the image before printing.

- Cut the design, leaving a small margin around the edges.

- Pre-press the product briefly to remove moisture.

- Place the sublimation paper on the product, secure it with heat-resistant tape, and cover it with a protective sheet.

- Press using the recommended time and temperature for your material.

- Remove the paper and allow the product to cool completely.

Foil application step:

7. Place the foil transfer sheet over the areas where you want metallic shine.

8. Cover with a protective sheet and press again at the foil manufacturer’s recommended settings.

9. Peel away the foil carefully once cooled and inspect the finish.

Best Uses for Foil Sublimation

- Logos and brand accents

- Titles and headings on notebooks

- Decorative plaques and signs

- Premium gift items

Pro Tips for a Clean Metallic Finish

- Use bold shapes, foil doesn’t love tiny details

- Avoid over-pressing, too much heat dulls shine

- Test foil color on scrap blanks first

- Let the product cool before peeling for sharper edges

Foil sublimation works best as a highlight, not the whole design. A little shine goes a long way.

🚀 Elevate Your Printing Game

Professional printing resources for stunning results

Frequently Asked Questions

Can beginners try these sublimation techniques?

Yes, beginners can start with distressed or tie-dye sublimation since they’re forgiving and don’t require advanced setup or layering skills.

Do I need special equipment for glitter or foil sublimation?

You don’t need a new printer, but you do need glitter sublimation paper or foil transfer sheets that are made for heat press use.

Which sublimation technique works best for selling products?

Layering, glitter, and foil sublimation tend to sell best because they create premium-looking designs that stand out from basic prints.

Can I use these techniques on cotton fabrics?

Most techniques work best on polyester or poly-coated items. Cotton usually needs special treatments or will produce faded results.

Is it okay to combine multiple sublimation techniques?

Yes, but it’s best to master one technique at a time before combining them to avoid over-pressing or design overload.

Do these techniques affect wash durability?

When done correctly, the designs stay durable. Over-pressing or using the wrong material is what usually causes fading or damage.

What to Try First

If you’re just getting started, pick one technique and test it on scrap material before moving on. Distressed and tie-dye sublimation are great entry points because they’re forgiving and still look intentional even when the results aren’t perfect.

Once you’re comfortable, step into glitter or foil sublimation to create designs that feel more premium and stand out in photos and listings.

To get consistent results, dial in your setup, material choice, and press settings before experimenting further. Small adjustments often make a bigger difference than changing the design itself.

If you want to go deeper, explore more hands-on tutorials and practical guides in our How-to Guide section and start turning these techniques into products people actually want to buy.

One Comment