A Complete Guide: What Temperature for Sublimation Tumbler

To achieve perfect prints on your sublimation tumblers, it’s crucial to get the temperature and time settings just right. Incorrect settings can lead to a range of issues, from colors that don’t pop to images that appear blurry.

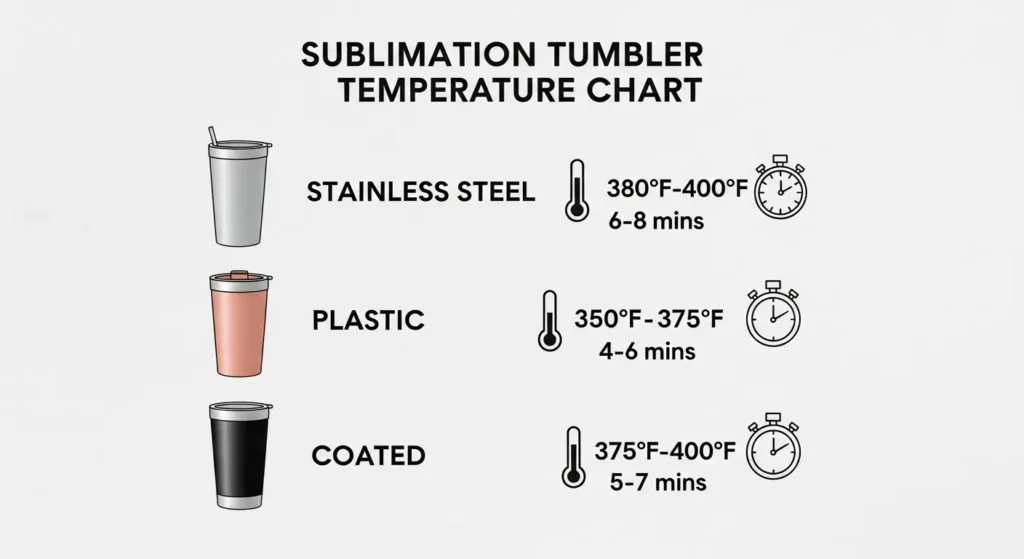

Our guide provides a comprehensive overview of the optimal temperature and time for various types of tumblers, including stainless steel, plastic, and coated materials.

The perfect sublimation tumbler temperature usually falls between 375°F and 400°F, but factors like tumbler material, coating, and heat press type can shift that slightly. Preheating, steady pressure, and testing will give you vibrant, lasting prints every time. Keep experimenting, the best settings come from your own setup.

What Temperature for Sublimation Tumbler

The ideal temperature for sublimating tumblers can vary depending on several factors but generally falls within the range of 375°F to 400°F (190°C to 205°C). Here’s a breakdown to help you navigate this:

General Range:

- Standard: Most tumblers can be sublimated at 380°F to 400°F (193°C to 204°C) for 6-8 minutes.

- Lower Temps: Some manufacturers may recommend slightly lower temperatures, like 375°F (190°C), especially for thinner tumblers or those with unique shapes.

Specific Factors:

- Tumbler Brand/Material: Always check the manufacturer’s recommendations for specific temperatures and timing for your particular tumbler. The instructions with the tumbler or the manufacturer’s website are your best sources for guaranteed success.

- Oven Type: Convection ovens are preferred for even heat distribution. If using a non-convection oven, it’s best to err on a slightly lower temperature side and monitor the process closely.

- Tumbler Size/Thickness: Thicker tumblers may require slightly higher temperatures or longer pressing times.

Common Sublimation Tumbler Problems (and Fixes)

| Problem | Likely Cause | Quick Fix |

|---|---|---|

| Faded colors | Low temperature or short time | Increase temp to 385–400°F |

| Ghosting or blurry edges | Paper shifted during press | Use heat-resistant tape firmly |

| Uneven color | Inconsistent heat | Rotate in oven or use convection |

| Melting or discoloration | Overheating plastic | Lower temp to 350°F–360°F |

| Print peeling off | Incompatible coating | Use sublimation-ready blanks only |

Cheat Sheet Sublimation Heat Press Temperature Chart

Please note that these are typical settings and may need to be adjusted based on your specific equipment, materials, and environmental conditions.

| Substrate | Temperature | Time | Pressure | Notes |

|---|---|---|---|---|

| T-Shirts | 380°F (193°C) | 30-40 seconds | Medium | Pre-press to remove moisture |

| Tumblers | 360°F (182°C) | 60-75 seconds | Firm | Rotate for even heat distribution |

| Mouse Pads | 400°F (204°C) | 40-60 seconds | Medium | Use a silicone pad for even pressure |

| Ceramic Tiles | 400°F (204°C) | 4-5 minutes | Light | Allow to cool before handling |

| Metal Sheets | 390°F (199°C) | 60 seconds | Firm | Use protective paper |

| Phone Cases | 375°F (191°C) | 60-75 seconds | Medium | Use silicone pad for even pressure |

| Polyester Fabric | 385°F (196°C) | 30-40 seconds | Medium | Stretch fabric before pressing |

| Glass | 400°F (204°C) | 6-7 minutes | Light | Use caution, glass may shatter |

| Hardboard | 375°F (191°C) | 60-75 seconds | Firm | Pre-press to remove moisture |

Remember:

- Always test on a small sample before full production.

- Adjust settings as needed based on results.

- Use appropriate protective gear and follow safety guidelines.

- Some substrates may require special coatings or treatments for sublimation.

Download the Temperature Chart PDF: Access a comprehensive chart that provides precise temperature guidelines for various tumbler materials.

Temperature Guidelines for Various Tumblers:

| Tumbler Type | Temperature (°F) | Time (Minutes) | Pressure |

|---|---|---|---|

| Stainless Steel | 375-400 | 6-8 | Medium |

| Plastic | 350-375 | 4-6 | Medium |

| Coated | 375-400 | 5-7 | Medium |

Experience a new level of vibrancy in your prints with my guide on the Power of UV Light for Sublimation.

Keep in mind that different tumbler materials may require slight adjustments in temperature settings. Proper temperature control is crucial in achieving optimal sublimation results on tumblers.

Factors Affecting Temperature:

- Tumbler Material: Different tumbler materials, such as stainless steel, aluminum, or ceramic, have varying heat conductivity properties. This can impact the required temperature and the duration of the sublimation process.

- Ink and Paper Compatibility: The sublimation ink and paper you use should be compatible with the specific temperature range recommended for the best results. Consult the product manuals or manufacturer’s instructions to ensure proper pairing.

- Heat Press Specifications: The heat press machine’s temperature accuracy and consistency are crucial for achieving reliable results. Regular calibration and maintenance are essential to ensure accurate temperature control.

Explore the intricacies of the settings and enhance your printing experience. For in-depth insights, check out the guide on Sublimation Printer Settings.

Tips for Successful Sublimation Tumbler Printing:

- Preheating the Tumbler: Preheating the Tumbler for a few seconds before applying the design helps remove any moisture or contaminants on the surface, ensuring better ink adhesion.

- Time and Temperature Control: Follow the recommended temperature and time settings for your specific tumbler and sublimation system. Maintaining consistent heat and pressure throughout the printing process is important.

- Testing and Calibration: Conduct test prints on sample tumblers to fine-tune the temperature settings and evaluate the color saturation and clarity of the prints. Regularly calibrate your equipment to ensure accurate temperature readings.

- Heat-Resistant Tape: Use heat-resistant tape to secure the transfer paper onto the tumbler. This prevents shifting during the heat press process, resulting in cleaner and more precise prints.

- Cooling and Finishing: Allow the tumbler to cool down naturally after printing. Avoid immediate contact with cold surfaces or water, as this can affect the outcome and longevity of the print.

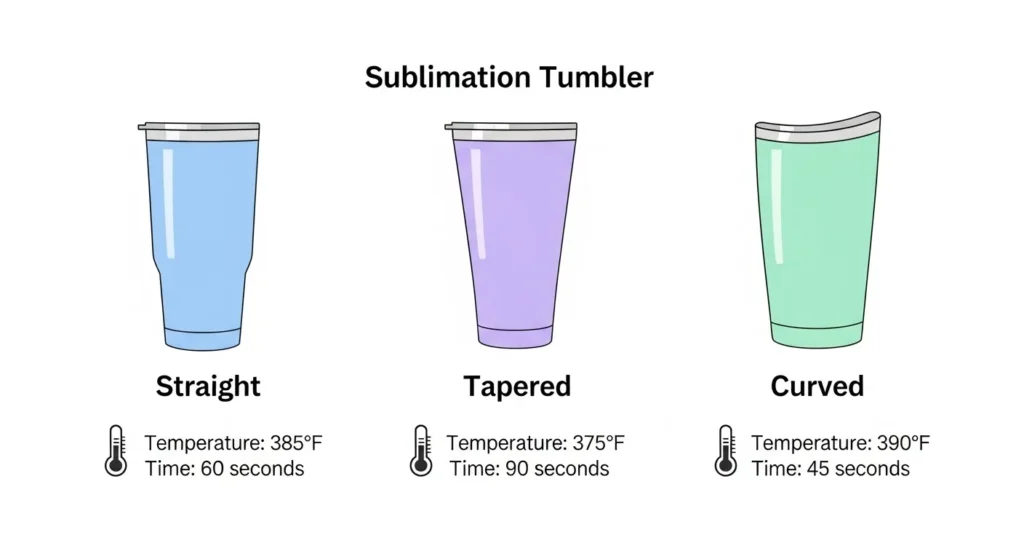

Do Different Tumbler Shapes Affect Temperature?

Yes, they do, tumbler shape actually plays a big role in how evenly the heat transfers.

When you switch between straight and tapered tumblers, you’ll notice slight differences in how the print wraps and how long it takes to fully sublimate.

Straight Tumblers (Easiest to Sublimate)

- Even Heat Contact: Straight tumblers have flat sides, so they get uniform heat from the press or oven.

- Best Settings: Stick with 380°F–400°F for 6–8 minutes at medium pressure.

- Tip: Always wrap the design snugly and use heat tape along the seam to avoid ghosting.

Ideal for: Beginners, or anyone doing full-wrap designs or all-over prints.

Tapered Tumblers (Trickier but Worth It)

- Uneven Heat Zones: Because of the curved shape, the bottom can get more pressure than the top.

- Best Settings: Drop the temperature slightly to 375°F–385°F and extend the time by 30–60 seconds.

- Tip: Use a silicone wrap or shrink wrap sleeve for even pressure. Rotate the tumbler halfway through if you’re using a convection oven.

Ideal for: Advanced users who want sleek, contoured tumbler shapes like travel mugs or wine tumblers.

Quick Shape Comparison

| Shape Type | Temp (°F) | Time (Minutes) | Difficulty | Pro Tip |

|---|---|---|---|---|

| Straight | 380–400 | 6–8 | Easy | Wrap snugly, even pressure |

| Tapered | 375–385 | 7–9 | Moderate | Use shrink wrap, rotate halfway |

| Skinny | 385–395 | 6–7 | Medium | Check for tight edge seal |

| Curved | 375–380 | 8–9 | Advanced | Preheat longer for even color |

💡 Pro Insight:

If you’re using a tumbler press, always match the heat element size to your tumbler’s shape. A press made for straight tumblers won’t hug a tapered one correctly, and that’s where color fades or white gaps appear.

Explore our full collection of quality sublimation blanks and substrates, perfect complements to the temperature guide you just reviewed.

Best Tools for Consistent Sublimation Results

Getting the temperature right is one thing, keeping it consistent is where the magic happens. Uneven heat is one of the top reasons prints come out faded, patchy, or off-color. The good news? The right tools make all the difference.

🧑🔧 Recommended Convection Ovens for Tumblers

| Oven | Why It’s Great | Ideal For |

|---|---|---|

| Hamilton Beach Convection Oven | Even air circulation and precise temp control | Beginners and small-batch makers |

| Breville Smart Oven Air Fryer Pro | Excellent temperature accuracy, built-in fan | Pro-level or frequent use |

| Oster French Door Oven | Wide interior fits multiple tumblers | Batch production |

| COSORI Air Fryer Oven Combo | Compact with multi-function use | Hobbyists or home setups |

💡 Pro Tip: Avoid using your kitchen oven for sublimation, the fumes from sublimation coatings aren’t food-safe. Always keep a dedicated oven for printing use only.

🔥 Wraps, Sleeves, and Accessories That Help

| Tool | Use | Benefit |

|---|---|---|

| Shrink Wrap Sleeves | Covers tumbler fully in oven | Delivers even pressure and no air bubbles |

| Silicone Wraps | Reusable, eco-friendly alternative to shrink wraps | Great for tapered tumblers |

| Heat-Resistant Tape | Holds your design firmly | Prevents shifting and ghosting |

| Tumbler Stands or Racks | Keeps tumblers stable in oven | Ensures smooth rotation and airflow |

👉 Using these tools together gives you steady pressure, balanced temperature, and professional-looking results on every tumbler.

Why Temperature Consistency Matters (The Science Behind Sublimation)

Here’s the cool part, sublimation isn’t just about art, it’s about chemistry.

When the temperature hits that sweet zone (around 375°F–400°F), the solid sublimation dye turns directly into gas, skipping the liquid phase. That gas then bonds with the polyester coating on your tumbler.

But here’s why consistency is so important:

- If the temperature drops, the dye doesn’t fully vaporize, leading to dull, faded colors.

- If it spikes too high, the coating can overheat and cause yellowing or smudging.

- Uneven heating (like from a low-quality press or oven) causes color shifts, darker on one side, lighter on the other.

Think of it like baking: the right temperature makes a perfect rise. Too hot or too cold, and it collapses.

How to Sublimate a Tumbler at the Right Temperature

Sublimating tumblers isn’t just about heat, it’s about timing, prep, and precision. Here’s the simple process to get perfect, long-lasting prints every time.

Step 1: Preheat the Tumbler

Before you start, preheat your tumbler for 5–10 seconds. This removes any moisture or residue that could mess with your print quality. A clean, warm surface helps the ink transfer evenly.

Step 2: Wrap the Design Securely

Print your design on sublimation paper, then wrap it tightly around the tumbler. Use heat-resistant tape to keep it from shifting during pressing. Make sure the edges are smooth, any air gaps can cause ghosting.

Step 3: Set Your Temperature and Time

Heat your press or convection oven to 380°F–400°F (193°C–204°C).

Press for 6–8 minutes using medium pressure.

If your tumbler is thicker or double-walled, add an extra 30 seconds to a minute for full color transfer.

Step 4: Let It Cool Naturally

Once you’re done, remove the paper carefully and let the tumbler cool at room temperature. Don’t place it in water or near cold surfaces, sudden temperature changes can damage the coating or dull the colors.

Pro Tips:

- Always check your manufacturer’s recommendations first.

- Rotate your tumbler during pressing if you’re using an oven for even heat.

- Do a quick test print before full production to fine-tune your setup.

Top Causes of Sublimation Print Errors (2025 Survey Snapshot)

Based on a 2025 industry snapshot. Use as directional insight and update with your own data if available.

Printable Temperature Tracker for Tumblers

Every sublimation setup is a little different, your press, ink, and tumbler brand all play a role in how the final print turns out. That’s why having a simple temperature tracker makes such a big difference.

Instead of guessing each time, record your best settings so you can repeat perfect results with confidence. Download Now: “Track every print, perfect your process.”

🎯 What’s Inside the Tracker

Your free Sublimation Temperature Tracker (PDF) includes:

- ✅ Tumbler Type & Material: Stainless steel, plastic, or coated

- ✅ Brand Name: Note the manufacturer or blank supplier

- ✅ Temperature Range: Record what worked best (e.g. 380°F for 7 min)

- ✅ Ink & Paper Brand: Track which combo gave the richest colors

- ✅ Pressure & Wrap Type: Shrink wrap, silicone sleeve, or heat press

- ✅ Color Outcome Notes: Quick space to jot results (e.g. “Perfect red saturation” or “slightly faded blue”)

🚀 Elevate Your Printing Game

Professional printing resources for stunning results

Conclusion:

Mastering the ideal temperature for sublimation tumblers is key to achieving remarkable printing results. By understanding the sublimation process, considering various factors, and implementing the recommended temperature range, you can create personalized tumblers that are vibrant, durable, and visually stunning. Experiment, learn from experience, and enjoy the art of sublimation tumbler printing.

Remember, it’s always beneficial to refer to the user manuals and seek guidance from experienced sublimation printing professionals to address specific concerns and ensure optimal results with your sublimation tumblers.