How to Remove Sublimation Print from Polyester

To remove sublimation print from polyester, gently dab the design with acetone using a cotton ball, testing a small area first. For white fabrics, try a diluted bleach solution (1:10 with water). Use a heat press to fade prints or cover with a new design. Work carefully to avoid damaging the fabric.

Removing fabric without damaging it isn’t always possible, but there are ways to partially remove or fade the print enough to reuse the item or correct a mistake.

Why Is It Challenging?

Sublimation printing involves dye penetrating and bonding with the polyester fibers at a molecular level under high heat.

This makes it durable and resistant to fading, but it also means traditional washing or scrubbing won’t work.

The key is to use techniques that can break down or lift the ink without ruining the fabric.

Methods to Remove or Fade Sublimation Print from Polyester

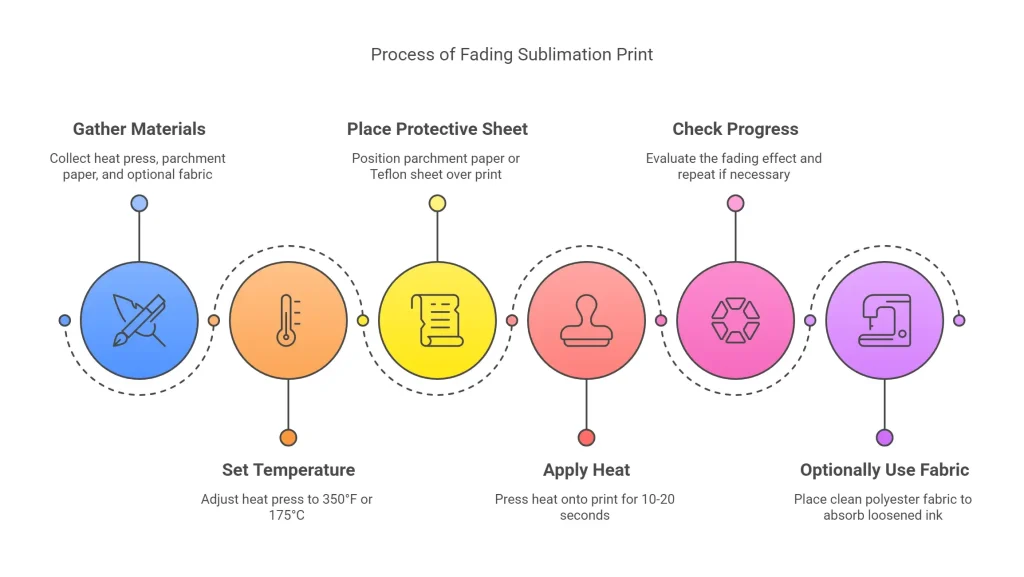

1. Using Heat to Fade the Print

Since sublimation ink activates with heat, applying heat again might help loosen or fade it. This method works best for lightening a print rather than fully removing it.

- What You’ll Need:

- Heat press or iron

- Parchment paper or Teflon sheet

- A clean, plain polyester fabric (optional)

- Steps:

- Set your heat press or iron to a temperature slightly lower than what was used for the original sublimation (around 350°F or 175°C).

- Place parchment paper or a Teflon sheet over the sublimation print to protect the fabric and prevent sticking.

- Press the heat onto the print for 10-20 seconds. Check the progress and repeat if needed, but avoid overheating to prevent melting the polyester.

- Optionally, place a clean piece of polyester fabric over the print before pressing—it might absorb some of the loosened ink.

This won’t erase the print completely but can fade it enough for reprinting.

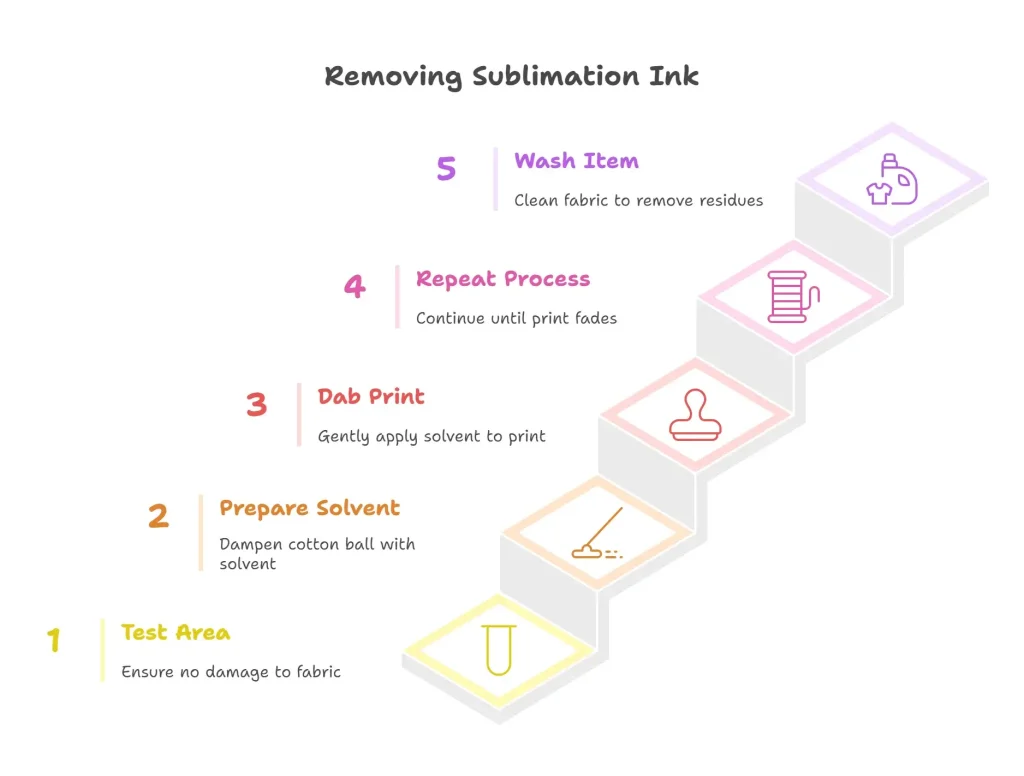

2. Chemical Solvents (Acetone or Rubbing Alcohol)

Certain chemicals can break down sublimation ink, though they must be used cautiously to avoid damaging the polyester.

- What You’ll Need:

- Acetone (nail polish remover) or isopropyl alcohol (70% or higher)

- Cotton balls or a soft cloth

- Gloves and a well-ventilated area

- Steps:

- Test a small, hidden area of the polyester item first to ensure it doesn’t ruin the fabric or cause discoloration.

- Dampen a cotton ball or cloth with acetone or rubbing alcohol.

- Gently dab (don’t rub) the sublimation print. Rubbing can spread the ink or damage the fibers.

- Repeat as needed, using fresh cotton balls, until the print fades.

- Wash the item with mild detergent and cold water to remove any chemical residue.

This won’t erase the print completely but can fade it enough for reprinting.

2. Chemical Solvents (Acetone, Rubbing Alcohol, or HTV Remover)

Certain chemicals can break down sublimation ink, but they need careful handling to avoid damaging polyester. Acetone, rubbing alcohol, or heat transfer vinyl (HTV) remover can work, especially for stubborn prints.

What You’ll Need:

- Acetone (nail polish remover) or isopropyl alcohol (70% or higher)

- HTV remover (optional, formulated for adhesive breakdown)

- Cotton balls, swabs, or a soft cloth

- Gloves and a well-ventilated area

Steps:

- Test a small, hidden area (like an inside seam) to check for fabric damage or discoloration.

- Dampen a cotton ball or cloth with your chosen solvent (acetone, alcohol, or HTV remover).

- Gently dab the print, don’t rub, as it can spread ink or harm fibers.

- Repeat with fresh cotton balls until the print fades. Follow HTV remover instructions if used (usually let it sit for a few minutes before wiping).

- Wash the item with mild detergent and cold water to remove chemical residue.

Caution: Overusing acetone or HTV remover can weaken polyester, so go light and stop if you see damage.

Pros: Quick and effective for tough prints.

Cons: Strong fumes require ventilation; can damage fabric if overdone.

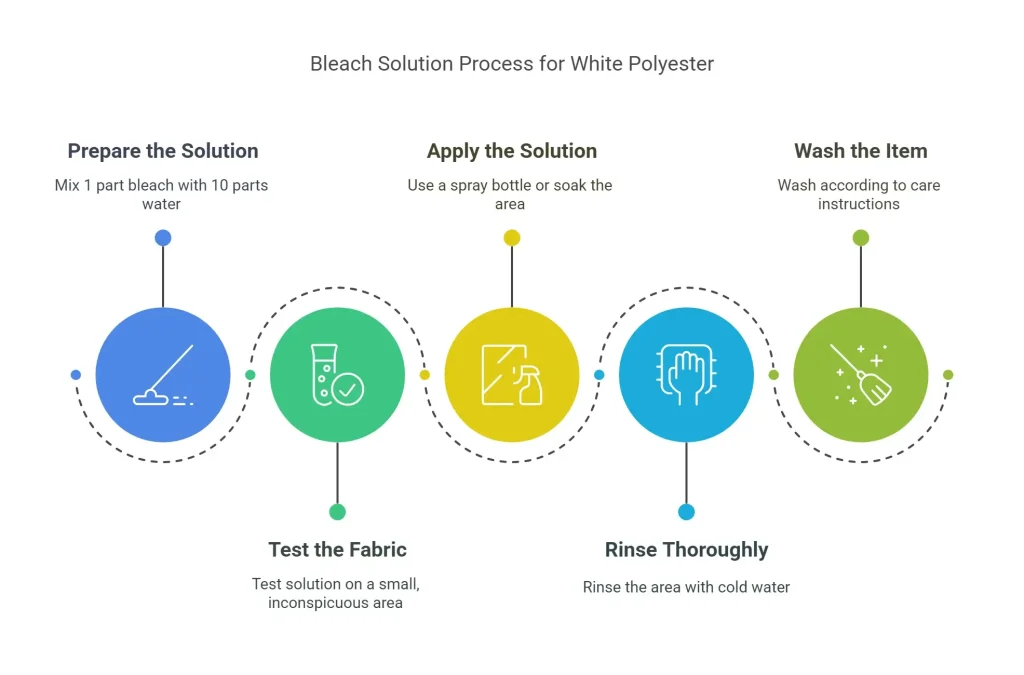

3. Bleach Solution (For White Polyester Only)

If your polyester item is white, a diluted bleach solution might help fade the print significantly.

- What You’ll Need:

- Bleach (household chlorine bleach)

- Water

- A spray bottle or bowl

- Gloves

- Steps:

- Mix 1 part bleach with 10 parts water to create a weak solution.

- Test on a small area first to check for fabric reaction.

- Apply the solution to the print using a spray bottle or by soaking the area in a bowl for 5-10 minutes.

- Rinse thoroughly with cold water and wash the item immediately.

NOTE

Only use on white polyester, bleach will ruin dyed fabrics.

4. Overprinting with a New Design

If removal isn’t fully successful or you’re fixing a mistake, consider covering the old print with a new sublimation design.

- What You’ll Need:

- New sublimation paper and ink

- Heat press

- Steps:

- Design a new print that’s darker or larger than the existing one to cover it effectively.

- Use your heat press at the standard sublimation settings (typically 400°F or 205°C for 40-60 seconds).

- Press the new design over the old print.

- Tip: This works best if the original print has been faded using one of the methods above.

5. Non-Chemical Methods

If you’re wary of chemicals, try these hands-on approaches to fade or remove prints without solvents.

Scraping and Rubbing:

This method uses physical effort to lift dye, ideal if you want to avoid harsh chemicals.

What You’ll Need:

- Plastic scraper (or an old credit card)

- Rags or paper towels

- Gloves (optional)

Steps:

- Gently scrape the design with a plastic scraper, taking care not to tear the fabric.

- Use a rag or paper towel to rub the area lightly in a circular motion to lift more dye.

- Repeat until you’ve removed as much dye as possible—it takes patience!

- Wash with mild detergent and cold water to clear residue.

Pros: No chemicals, simple tools.

Cons: Time-consuming, may leave some dye behind.

Safety Note: Go easy to avoid fraying or stretching polyester.

Special Case: Polyester-Coated Tumblers

For sublimation prints on polyester-coated items like tumblers, the process differs slightly because the coating is a thin layer over a hard surface (usually metal).

- Method:

- Use acetone or a stronger solvent like paint thinner.

- Apply with a cloth and wipe gently to lift the ink from the coating.

- If the coating itself starts to come off, stop immediately, as it can’t be reapplied easily.

Tumblers may need re-coating and reprinting if the original coating is damaged.

Tips to Protect Your Polyester Item

- Avoid Harsh Scrubbing: Polyester fibers can fray or pill if treated too roughly.

- Test First: Always try any method on a small, inconspicuous area to avoid widespread damage.

- Act Quickly: Mistakes are easier to address if you attempt removal soon after printing, before the ink fully sets.

Sublimation Removal Methods Comparison

Comparison of Methods

Using Sublimation Ink Remover

Sublimation ink removers are specialized solvents designed to break down sublimation dyes on various surfaces, including polyester and mug coatings. They’re often stronger than household options like acetone but require extra care.

What You’ll Need:

- Sublimation ink remover

- Cotton balls or soft cloth

- Gloves, safety goggles, and a well-ventilated area

Steps for Polyester:

- Test on a small, hidden area to ensure fabric safety.

- Apply the remover to a cotton ball or cloth per product instructions.

- Dab gently on the print, avoiding heavy rubbing.

- Repeat until the ink fades, using fresh cotton balls.

- Wash with mild detergent and cold water.

Steps for Mugs:

- Test on a small area of the mug’s coating.

- Apply the remover with a cloth, wiping gently to lift ink.

- Rinse thoroughly with warm water and dish soap.

- Dry completely before reusing or reprinting.

Pros: Highly effective, formulated for sublimation ink.

Cons: Expensive, strong fumes require ventilation.

Safety Note: Always follow the remover’s label instructions. Wear gloves and goggles, and work in a well-ventilated space to avoid inhaling fumes.

Tips to Protect Your Items

- Test First: Try any method on a small area to avoid damage.

- Act Quickly: Fresh prints are easier to fade than set-in ones.

- Avoid Harsh Scrubbing: Polyester frays, and mugs can scratch.

- Use Dedicated Tools: Keep ovens or brushes for crafting separate from food prep.

Common Mistakes to Avoid

- Overusing Solvents: Too much acetone or ink remover can ruin polyester or mug coatings.

- Skipping Tests: Always check a small spot first to avoid disasters.

- Using Bleach on Colored Items: It’ll wreck dyed polyester or mug designs.

- Overheating: Too much heat can melt polyester or crack mugs.

Comparison of Methods

| Method | Effectiveness | Cost | Risk to Material | Best For |

|---|---|---|---|---|

| Heat Press (Polyester) | Moderate | Low | Low | Fading light prints |

| Solvents/Remover | High | Low-Medium | Medium | Stubborn prints on both |

| Bleach (White Polyester) | High | Low | High | White polyester only |

| Overprinting | High | Medium | Low | Covering mistakes |

| Scraping/Rubbing | Low | Low | Medium | Chemical-free polyester fading |

| Dishwasher (Mugs) | Moderate | Low | Low | Gradual mug fading |

| Vinegar Soak (Mugs) | Moderate | Low | Low | Eco-friendly mug cleaning |

| Oven (Mugs) | High | Low | Medium | Fast mug fading |

Using Heat Transfer Vinyl Remover

Heat transfer vinyl (HTV) remover is a chemical solution designed to break down the adhesive bond between HTV and fabric, making it a handy tool for removing sublimation prints from polyester. Choose a remover specifically made for HTV to avoid damaging your fabric.

Pros

- ✅Highly effective, even on stubborn prints

- ✅Easy to use with minimal tools

- ✅Safe for most fabrics (with a quick test)

Cons

- ❌Can damage fabric if overused

- ❌Strong fumes—ventilation is a must

- ❌Not always needed for minor mistakes

Step-by-Step Instructions

- Gather your tools: HTV remover, cotton swabs or an applicator, rags or paper towels, and gloves.

- Follow the manufacturer’s instructions carefully for safe use.

- Apply the remover to a small, hidden area of the fabric to check for damage.

- If the test area is fine, apply the remover across the entire design.

- Let it sit for a few minutes (as per instructions), then gently peel off the HTV.

- Repeat if needed to lift all the HTV.

- Wash the fabric with mild detergent and cold water to remove any residue.

Safety Note: Work in a well-ventilated area, wear gloves, and avoid overusing the remover to protect your fabric.

Scraping and Rubbing

Scraping and rubbing involve physically removing the sublimation dye from the fabric using a scraping tool and a rubbing motion. This hands-on method skips harsh chemicals, making it perfect if you prefer a manual approach to tackle that stubborn dye!

Pros

- ✅No harsh chemicals needed

- ✅Can be done at home with simple tools

Cons

- ❌Time-consuming and requires patience

- ❌May leave some dye residue behind

Step-by-Step Instructions

- Gather your tools: a plastic scraper (or an old credit card), rags or paper towels, and gloves (optional).

- Apply a gentle scraping motion to the design with your scraping tool, being careful not to damage the fabric.

- Use a rag or paper towel to rub the area lightly in a circular motion to lift more dye.

- Repeat the scraping and rubbing until as much dye as possible is removed—patience is key!

- Wash the fabric with mild detergent and cold water to clean up any leftover residue.

Safety Note: Go easy with the scraping and rubbing to avoid tearing or stretching the polyester. Take your time!

Why Polyester Is Tricky

Polyester’s a tough, quick-drying fabric that shrugs off wrinkles, making it awesome for workout gear or casual clothes. But its durability is why sublimation ink sticks so well, it bonds deep into the fibers under heat. To remove it, you need the right prep to avoid wrecking your shirt.

Prep Like a Pro

Good prep makes removing sublimation ink easier and safer. Here’s what to do before you start.

1. Grab Your Tools

Have these ready to tackle the job:

- Solvents: Acetone (nail polish remover), isopropyl alcohol (70%+), or heat transfer vinyl (HTV) remover for breaking down ink. Use sparingly to protect polyester.

- Scraping Tool: Plastic scraper or old credit card to lift ink gently. Avoid metal, it can tear fabric.

- Cleaning Supplies: Cotton balls, rags, or paper towels for applying solvents; mild detergent for washing after.

- Protective Gear: Gloves, safety goggles, and a mask for chemical safety.

- Optional: Parchment paper or Teflon sheet for heat methods; spray bottle for precise solvent application.

Where to Get Them: Check hardware stores, craft shops, or online. Newbie? Start with alcohol, it’s gentler than acetone.

2. Get the Fabric Ready

- Wash It: Run the item through a cold-water wash with mild detergent to remove dirt or oils. Skip fabric softener or bleach, they mess things up.

- Test First: Dab a bit of solvent on a hidden spot (like an inside seam). Wait 5 minutes to check for damage or discoloration.

- Dry Fully: Make sure the fabric’s dry before starting, wet fabric dilutes solvents.

Tip: For pricey or delicate items, consider a professional cleaner with sublimation know-how.

3. Stay Safe

- Gear Up: Wear gloves and goggles; use a mask if fumes are strong.

- Ventilate: Open a window or work outside to avoid breathing chemicals.

- Follow Instructions: Check solvent labels for usage and disposal tips.

- Dispose Right: Soak up extra solvent with paper towels and seal in a bag. Try biodegradable options for an eco-friendly choice.

Quick Tips

- Act fast—fresh ink comes off easier.

- Go gentle to avoid fraying polyester.

- Nervous about chemicals? Use heat (iron with parchment paper) to fade prints.

- If removal fails, cover the print with a new design or repurpose the item into a bag or craft.

Why It Matters: Skipping prep can ruin your fabric or cause skin irritation. A little setup saves a lot of hassle.

Removing Sublimation Ink from Mugs

Sublimation ink on ceramic mugs bonds with a polyester coating, making it just as stubborn as on fabric. Here’s how to tackle it without cracking your mug.

1. Dishwasher Method

High heat and water can gradually fade sublimation ink from mugs.

What You’ll Need:

- Dishwasher-safe mug

- Dishwasher detergent

- Soft sponge or toothbrush

Steps:

- Place the mug on the top rack of your dishwasher.

- Set to a high-temperature cycle with regular detergent.

- Run multiple cycles (3-4) until the ink fades significantly.

- Scrub gently with a sponge or toothbrush to remove lingering traces.

- Rinse with hot water and air dry.

Note: This takes time but is low-effort. Results may vary based on mug coating.

2. Vinegar Soak

White or apple cider vinegar can loosen sublimation ink safely.

What You’ll Need:

- White or apple cider vinegar

- Bowl

- Soft sponge

- Mild dish soap

Steps:

- Fill a bowl with vinegar and submerge the mug’s printed area.

- Soak for 2-3 hours.

- Scrub gently with a sponge to lift the ink.

- Wash with dish soap and warm water, then dry.

Pros: Gentle, eco-friendly.

Cons: May not fully remove dark prints.

3. Convection Oven Method

High heat can fade ink by reversing the sublimation process.

What You’ll Need:

- Convection or toaster oven (not used for food)

- Dish soap

- Cotton pad and lemon juice (optional)

Steps:

- Wash the mug with dish soap and water to remove surface dirt.

- Place in a convection oven at 400°F for 30-60 minutes, checking every 15 minutes.

- Remove carefully (use oven gloves!) and let cool.

- Optional: Scrub with a lemon juice-soaked cotton pad for extra fading.

- Rinse with warm water.

Caution: Use a dedicated oven to avoid food contamination.

Using Sublimation Ink Remover

Sublimation ink removers are specialized solvents designed to break down sublimation dyes on various surfaces, including polyester and mug coatings. They’re often stronger than household options like acetone but require extra care.

What You’ll Need:

- Sublimation ink remover

- Cotton balls or soft cloth

- Gloves, safety goggles, and a well-ventilated area

Steps for Polyester:

- Test on a small, hidden area to ensure fabric safety.

- Apply the remover to a cotton ball or cloth per product instructions.

- Dab gently on the print, avoiding heavy rubbing.

- Repeat until the ink fades, using fresh cotton balls.

- Wash with mild detergent and cold water.

Steps for Mugs:

- Test on a small area of the mug’s coating.

- Apply the remover with a cloth, wiping gently to lift ink.

- Rinse thoroughly with warm water and dish soap.

- Dry completely before reusing or reprinting.

Pros: Highly effective, formulated for sublimation ink.

Cons: Expensive, strong fumes require ventilation.

Safety Note: Always follow the remover’s label instructions. Wear gloves and goggles, and work in a well-ventilated space to avoid inhaling fumes.

Learn everything about sublimation and printers with Subli Genius Print.

Access a complete guide with detailed steps and expert insights.

Eco-Friendly Tips

- Opt for vinegar or biodegradable ink removers to reduce environmental impact.

- Repurpose failed items into bags, patches, or practice pieces.

- Use isopropyl alcohol over acetone for a milder option on polyester.

FAQs

Glossary

- Sublimation Printing: Using heat and pressure to transfer dye into the fabric.

- Polyester Fabric: A synthetic material made from polyethylene terephthalate (PET) commonly used in clothing, upholstery, and other textiles.

- Solvents: Chemicals that dissolve other substances, often used for removing sublimation print from polyester fabric.

- Scraping Tools: Tools used to physically remove sublimation print from polyester fabric, such as a razor blade or scraper.

- Heat Transfer Vinyl Remover: A chemical solution designed explicitly for removing heat transfer vinyl and other adhesives from fabric.

- Protective Gloves and Eyewear: Safety equipment is worn to protect the user from harmful chemicals and debris while removing the sublimation print from polyester.

- Pre-treatment: The process of washing the fabric to remove dirt and oils before removing the sublimation print to improve the effectiveness of the removal process.