The Future of Sublimation:

The future of sublimation is full of exciting possibilities, from technological advancements and expanding applications to a focus on sustainability and innovation. As the industry evolves, businesses and consumers alike can look forward to more personalized, eco-friendly, and cutting-edge products.

Sublimation is a printing technique where ink is transformed into a gas and then embedded into a material. Unlike traditional printing methods that sit on top of the surface, sublimation allows the ink to become part of the material, creating vibrant and long-lasting designs.

The sublimation world is moving fast right now. New printers, smarter software, sustainability rules, shifting materials, everything is changing at the same time. If you’re trying to stay ahead or just want a quick look at what’s happening this year, here’s the latest sublimation printing news plus the biggest trends shaping what comes next. This guide mixes real updates with the long term moves that matter so you can see the full picture without digging through tons of pages.

Latest Sublimation Printing News 2025

• New eco-friendly sublimation inks rolling out from major suppliers

• Epson and Sawgrass expected to announce updated pro models in late 2025

• More US manufacturers shifting to recycled polyester and low-waste blanks

• AI-powered color management tools gaining adoption among mid-size shops

• Home decor and sportswear markets see double-digit growth this year

• Pressures for greener production pushing brands toward energy-efficient heat presses

• Rising interest in metal and rigid substrate sublimation for commercial products

The current state of the sublimation industry

Today, sublimation is a thriving industry known for its ability to produce high-quality, customized items quickly and efficiently. The technology has matured, with a variety of printers, inks, and materials available to suit different needs.

Businesses ranging from small startups to large corporations are utilizing sublimation to offer unique and personalized products to their customers.

Market snapshot — sublimation (USD, billions)

| Metric | Value (USD) |

|---|---|

| Dye sublimation printer market (2024) | $2.30B |

| Sublimation paper market (2025) | $1.40B |

| Projected printer market (2032) | $4.51B |

Teaser for the exciting future ahead

But what does the future hold for sublimation? As technology continues to advance, we are on the brink of seeing some truly exciting developments. From cutting-edge printers to new applications and sustainable practices, the next few years promise to bring significant changes to the sublimation landscape.

Stay tuned as we explore the trends, innovations, and opportunities shaping the future of this dynamic industry.

Technological Advancements

A. Next-generation sublimation printers

The world of sublimation printing is evolving with the introduction of next-generation printers. These advanced models offer improved resolution, faster printing speeds, and better color accuracy. Innovations such as larger print beds and enhanced automation are making it easier for businesses to handle larger volumes and more complex designs.

B. Improved inks and dyes

The quality of sublimation prints is heavily dependent on the inks and dyes used. Recent advancements in ink technology have led to the development of more vibrant and durable colors. New formulations are designed to offer better performance across a wider range of materials, ensuring that prints are sharp and long-lasting.

C. Software innovations for design and production

Software plays a crucial role in sublimation printing, influencing everything from design creation to production efficiency. Recent innovations in design software have made it easier to create intricate and customized designs. Tools for color management and image editing are becoming more sophisticated, allowing for precise control over the final output.

Table 1: Technological Advancements in Sublimation Printing

| Innovation | Description |

|---|---|

| High-Speed Printers | Devices capable of printing at significantly higher speeds, reducing production time. |

| Eco-Friendly Inks | Inks that minimize environmental impact through reduced VOC emissions and use of renewable resources. |

| Improved Heat Presses | Heat presses that offer better energy efficiency and uniform heat distribution for consistent quality. |

Market Expansion and Consumer Trends

The sublimation market is expanding into new territories, driven by consumer trends favoring personalized and bespoke products. From customized apparel to personalized home decor, the demand spans various sectors, offering ample opportunities for businesses.

- Personalization: The desire for personalized items continues to grow, with consumers seeking unique products that reflect their individuality.

- Sustainability: Eco-conscious consumers are influencing the market, pushing for products made with sustainable practices and materials.

List of Expanding Markets for Sublimation:

- Fashion and Apparel

- Home Decor

- Promotional Products

- Sports Equipment

- Outdoor Signage

Sustainability Efforts

The sublimation industry is increasingly focused on sustainability, seeking ways to minimize its environmental footprint. This includes the use of recycled materials, waste reduction practices, and the development of more eco-friendly sublimation processes.

- Recycled Fabrics: The use of recycled polyester and other materials in sublimation printing helps reduce waste and conserve resources.

- Waste Reduction Techniques: Innovations in printing technology aim to minimize ink and energy waste, contributing to more sustainable production processes.

Pie Chart: Distribution of Sustainability Efforts in Sublimation

- Recycled Materials Usage

- Energy-efficient Machinery

- Eco-friendly Inks

Emerging Opportunities

The future of sublimation holds exciting possibilities, from digital integration to new material applications. Digital platforms are streamlining the design-to-print process, while research into sublimation on unconventional materials opens up new product avenues.

- Digital Integration: Enhanced software solutions are simplifying the design process, enabling more intricate and customizable prints.

- New Material Applications: Ongoing research is expanding the range of materials suitable for sublimation, from synthetic fabrics to rigid products like ceramics and metal.

Table 2: Emerging Opportunities in Sublimation

| Opportunity | Impact |

|---|---|

| Digital Integration | Streamlines the design-to-print process, allowing for greater customization and efficiency. |

| New Materials | Expands the range of sublimation applications, offering new product opportunities. |

Sublimation Market Share and Growth in the USA:

The U.S. market for sublimation is a dynamic and growing segment driven by several factors, including:

- Increasing demand for personalized and customized products: This trend, evident in apparel, home decor, and promotional items, benefits from the high-quality, vibrant prints achievable with sublimation.

- Advancements in technology: Sublimation printers and inks are becoming more affordable and user-friendly, making the process accessible to a broader range of businesses and individuals.

- E-commerce growth: Online platforms facilitate custom product creation and direct-to-consumer sales, fueling the sublimation market.

Market Size and Growth:

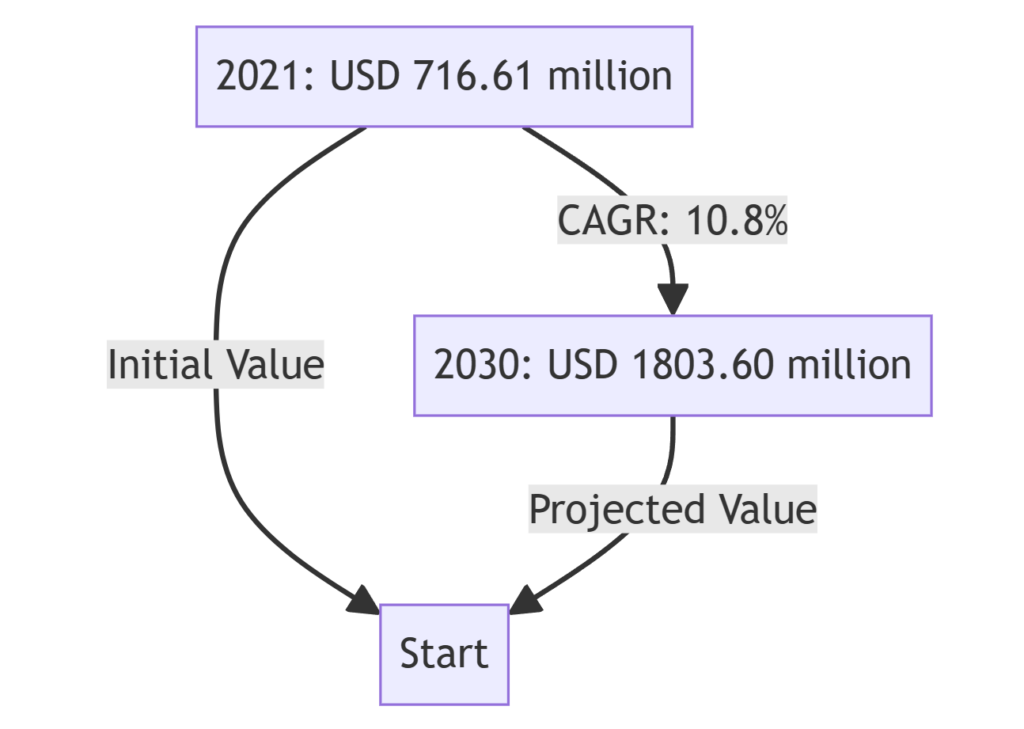

- The global dye sublimation printing ink market was valued at USD 716.61 million in 2021 and is projected to reach USD 1803.60 million by 2030, with a compound annual growth rate (CAGR) of 10.8% during the forecast period. (Source: Straits Research)

- The U.S. is a major contributor to this market, with the apparel segment expected to drive significant growth due to the rising demand for athletic wear, activewear, and fashion merchandise. (Source: Grand View Research)

- Another crucial segment is home decor, where sublimation printing allows for personalized and vibrant designs on various surfaces like mugs, cushions, blankets, and wall art. (Source: Mordor Intelligence)

Market Share:

- While specific market share data for the U.S. is hard to pin down due to segmentation and various players, prominent industry reports highlight the growing dominance of North America in the global sublimation market.

Additional Observations:

- The sublimation paper market is also experiencing steady growth, fueled by the increasing demand for quality printing media.

- The future of the U.S. sublimation market looks promising, with continued technological advancements, increasing consumer interest in customization, and the e-commerce boom expected to keep momentum.

Expanding Applications

A. Traditional markets (textiles, promotional items)

Sublimation has long been a staple in the textile and promotional items markets. In textiles, it’s widely used for creating custom apparel such as t-shirts, sportswear, and accessories. The ability to produce vibrant, durable designs makes it a favorite among fashion brands and event organizers.

B. Emerging markets (interior design, industrial applications)

Beyond the traditional markets, sublimation is making significant inroads into emerging areas. In interior design, sublimation is used to create custom wall art, decorative panels, and unique home furnishings. The technology’s ability to produce detailed and colorful designs on various substrates opens up new possibilities for interior decorators and designers.

In industrial applications, sublimation is finding uses in creating durable and high-quality components for machinery and equipment, where custom branding and design elements are increasingly in demand.

C. Customization and personalization trends

One of the most exciting trends in sublimation is the rise of customization and personalization. Consumers are increasingly seeking products that reflect their tastes and preferences. Sublimation meets this demand by offering endless possibilities for customization, from personalized gifts and custom apparel to unique home décor items.

Businesses that embrace this trend can cater to a growing market of customers looking for one-of-a-kind products that reflect their style.

The Role of Sublimation in Industry 4.0

A. Integration with smart manufacturing

As Industry 4.0 reshapes manufacturing, sublimation printing is increasingly integrating with smart technologies. This includes the use of IoT (Internet of Things) devices that enable real-time monitoring and control of printing processes.

Smart manufacturing systems can optimize production by adjusting parameters automatically based on data from sensors, ensuring consistent quality and reducing waste. This integration helps streamline operations and improve efficiency in sublimation printing.

B. On-demand production and mass customization

One of the key benefits of sublimation in the context of Industry 4.0 is its ability to support on-demand production and mass customization. Modern sublimation printers can quickly produce small batches of customized products, catering to individual customer preferences.

This flexibility aligns with the growing demand for personalized items and allows businesses to respond rapidly to market trends without the need for large inventories.

C. Data-driven design and production processes

Data-driven approaches are becoming central to modern manufacturing, including sublimation printing. Advanced software tools collect and analyze data from the design and production stages, providing insights that can drive improvements.

For instance, data on customer preferences and production performance can inform design decisions and process adjustments, leading to better outcomes and more efficient operations.

At Subli Genius Print, we are dedicated to staying at the forefront of these trends and helping you achieve your sublimation goals. What new trends or technologies in sublimation are you most excited about?

2 Comments