Polyester Sublimation Guide: Perfect Time & Temp Settings

Polyester sublimation requires a heat press set between 380°F to 400°F for 45–60 seconds. Use 100% polyester blanks for best color vibrancy.

This range lets sublimation dye turn into gas and bond at the molecular level, producing bright, permanent prints that resist fading or cracking.

Polyester is the gold standard for sublimation because its synthetic fibers open under heat, allowing dyes to fuse deeply. Cotton or low-poly blends can’t bond as well, leading to dull or uneven results. For best color and durability, use 100% polyester blanks or blends with at least 65% polyester.

Best Temperature for 100% Polyester

For 100% polyester, the ideal heat press range is:

- Temperature: 385–400°F (195–205°C)

- Time: 45–60 seconds

- Pressure: Medium, even pressure

This range allows sublimation dye to convert into gas and bond directly with the polyester fibers. Lower temperatures may result in dull or faded prints, while excessive heat can cause scorching or fabric shine.

For most standard polyester shirts, start at 385°F for 50 seconds with medium pressure. Adjust slightly higher for thicker garments like hoodies and slightly lower for lightweight performance fabrics.

Always pre-press the garment for 5–10 seconds to remove moisture before applying the transfer.

Time & Temp by Polyester Percentage

Polyester percentage directly affects dye bonding. The higher the polyester content, the stronger and more vibrant the result.

Recommended Settings by Blend

| Polyester Content | Temperature | Time | Pressure | Expected Result |

|---|---|---|---|---|

| 100% Polyester | 385–400°F | 45–60 sec | Medium | Bright, full color |

| 80–90% Polyester | 380–390°F | 45–55 sec | Medium | Strong color, minimal fading |

| 65/35 Poly-Cotton | 370–380°F | 50–55 sec | Medium-Light | Slightly softer / vintage tone |

| 50/50 Blend | 360–370°F | 35–45 sec | Light | Noticeably faded look |

What to Expect

- 80%+ polyester delivers consistent, vibrant prints.

- 65% polyester is the minimum recommended for solid color retention.

- Below 60% polyester, designs will appear faded because only the polyester fibers accept the dye.

If color vibrancy is the goal, use 100% polyester whenever possible.

Check more about Polyester Hoodie for Sublimation

According to Sawgrass Technologies and Brother Support, most garments sublimate perfectly at 385°F for 50 seconds, while thicker blanks like hoodies perform better around 390°F with firm pressure.

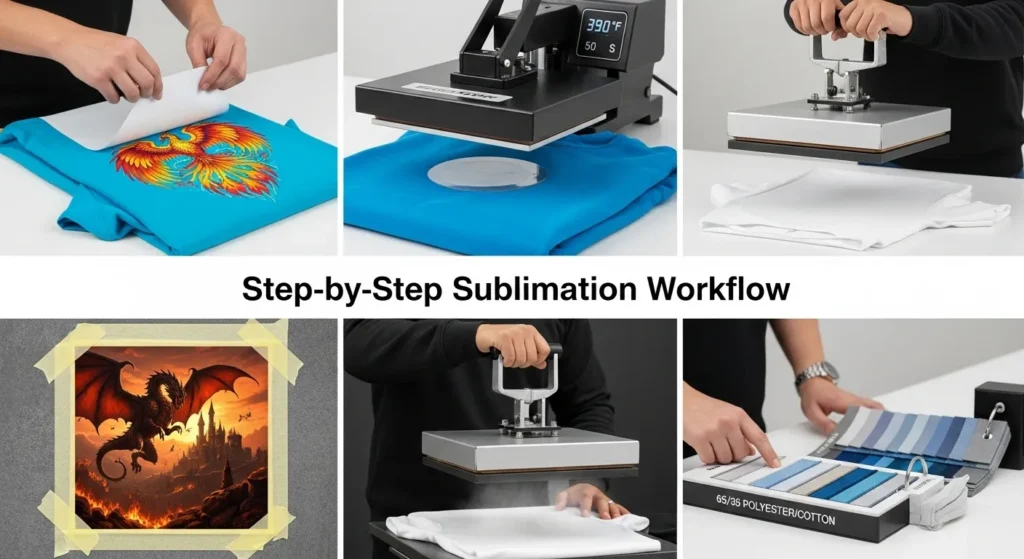

Step-by-Step Sublimation Workflow

Follow these five steps to sublimate polyester fabric correctly and get vibrant, lasting prints every time.

Step 1: Choose the Right Fabric

Use 100% polyester or blends with at least 65% polyester content. Lower polyester ratios lead to faded or vintage-looking prints because the dye cannot fully bond with cotton fibers. For photo-quality results, stick to pure polyester shirts, tote bags, or hoodies.

Step 2: Pre-Press the Fabric

Set your heat press to 380–400°F (195–205°C) and pre-press the blank for 5–10 seconds. This step removes trapped moisture and flattens wrinkles, preventing ghosting and uneven heat transfer later.

Step 3: Position and Secure the Design

Align the printed sublimation transfer face-down on the fabric. Secure it with heat-resistant tape at each corner to stop it from shifting when pressed. Even a small movement can cause blurred edges or double images.

Step 4: Set Press Parameters

Adjust your press to 385–400°F for 45–60 seconds using medium to firm pressure. Use the higher end of the range for thicker materials like hoodies and a few degrees lower for lightweight polyester. Consistent heat and pressure are key to sharp, even color transfer.

Step 5: Press, Peel, and Cool

When the timer ends, lift the press and peel the transfer sheet immediately for a glossy finish or after 10 seconds for a matte look. Lay the item flat to cool for 1–2 minutes before folding or packaging to prevent smudging.

✅ Pro Tip:

Always test new blanks or materials with a small transfer first. Different fabrics and presses vary slightly, and a test run helps you fine-tune temperature, time, and pressure settings before doing a full batch.

For a broader breakdown of compatible fabrics and surfaces, see our sublimation material guide.

Common Mistakes With Polyester Sublimation

- Using Low Polyester Blends

Fabrics under 65% polyester produce faded or washed-out results because the dye only bonds to synthetic fibers. - Pressing at Too Low a Temperature

Temperatures below 380°F often lead to dull colors and weak bonding. - Too Much Heat or Pressure

Excessive heat can cause scorching, fabric shine, or yellowing especially on lightweight garments. - Skipping the Pre-Press Step

Moisture trapped in fabric can cause ghosting or uneven transfer. - Uneven Pressure Distribution

Inconsistent pressure leads to patchy or blurry areas in the design.

Always test new blanks before full production runs to confirm your settings.

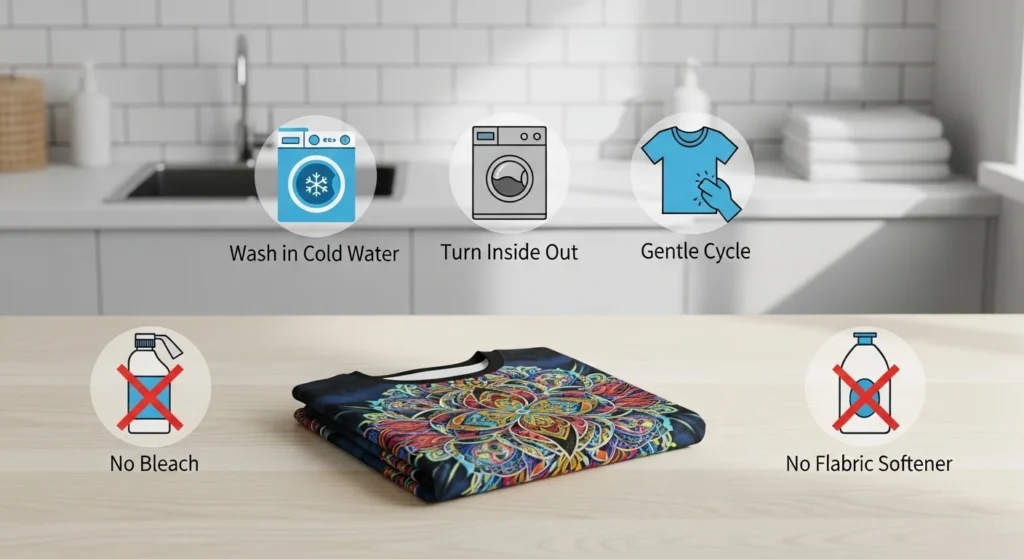

Care Tips & Maintaining Vibrancy

Proper washing and handling extend the life of sublimated designs. Following these tips keeps prints vibrant, sharp, and long-lasting, even after multiple washes.

Washing Instructions

- Turn garments inside out before washing

- Use cold water

- Select a gentle cycle

- Wash with similar colors to avoid dye transfer

Drying Guidelines

- Air dry whenever possible

- If using a machine, set to low heat or tumble dry low

- Avoid high heat, which can dull colors over time

What to Avoid

- Bleach or whitening agents

- Fabric softeners, which coat fibers and reduce brightness

- Ironing directly over the design

FAQs:

What is the best temperature for 100% polyester sublimation?

The ideal range is 385–400°F (195–205°C) for 45–60 seconds with medium pressure. Most standard shirts perform well at 385°F for 50 seconds.

How much polyester is needed for good sublimation results?

For strong color retention, use at least 65% polyester. For the most vibrant and long-lasting prints, choose 100% polyester.

Can you sublimate on 50/50 polyester blends?

Yes, but expect a faded or vintage look. Only the polyester fibers accept the dye, so color intensity will be reduced.

Why do my polyester prints look dull?

Common causes include pressing at too low a temperature, using low-polyester blends, or uneven pressure during transfer.

4 Comments