10 Expert Tips for Crafting Stellar Sublimation Coating Liquid

Have you ever marveled at those vibrant, detailed, and awe-inspiring images on ceramic mugs, phone cases, or fabric? Chances are, you’ve encountered sublimation printing – a remarkable technique that transfers intricate designs onto various surfaces.

The magic behind this process lies in the sublimation coating liquid, a crucial element that paves the way for stunning creations.

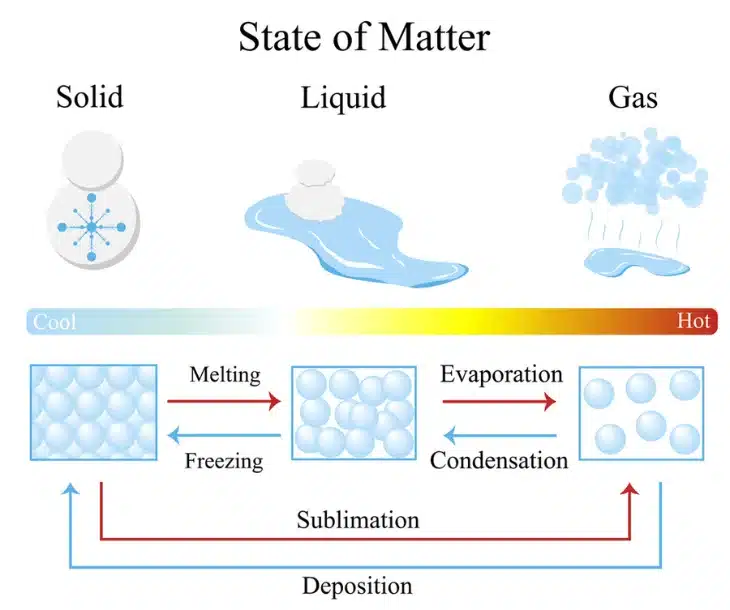

1. Understanding the Essence of Coating Liquid

At its core, it is a specially formulated solution that bridges digital designs and physical surfaces. It’s the secret ingredient that makes sublimation printing a reality. When applied to surfaces like ceramics, metals, or fabrics, this coating enables the ink to bond permanently with the material upon heating, resulting in vibrant and long-lasting images.

2. Crafting Your Own Sublimation Coating Liquid: Where to Begin

Creating sublimation with liquid coating might sound like a complex task, but with the proper guidance, it’s entirely achievable. The main components of the drink include a carrier solution, a sublimation-friendly binder, and a surface-enhancing additive. Combining these elements in proportions is critical to producing a high-quality coating liquid.

3. Navigating the Ingredients: A Deep Dive

Carrier Solution: This forms the base of the coating liquid, providing the necessary viscosity for easy application. A mixture of distilled water and isopropyl alcohol is commonly used, creating a balance between water-based and alcohol-based properties.

Sublimation-Friendly Binder: The binder holds the sublimation dye particles in place, ensuring they adhere to the material during heating. A popular choice is polyvinyl alcohol (PVA), which is water-soluble and compatible with sublimation inks.

Surface-Enhancing Additive: Enhancing the surface tension of the coating liquid is vital for proper ink absorption and adhesion. Surfactants, like non-ionic wetting agents, can be added to achieve this effect.

4. Measuring and Mixing: Precision Matters

Creating an effective sublimation coating liquid requires precision in measuring and mixing. Utilize a digital scale to ensure accurate measurements of each ingredient. Mixing should be done gradually, providing a homogenous solution without clumps or sediment.

5. Fine-Tuning Viscosity for Optimal Application

The viscosity of your coating liquid plays a significant role in its application. Aim for a density similar to milk’s; this consistency ensures even and smooth application on various surfaces. You can adjust viscosity by adding distilled water or isopropyl alcohol in small increments.

6. Application Techniques: From Spray to Dip

Once your sublimation coating liquid is ready, it’s time to apply it to your chosen surfaces. Different application techniques can be used, such as spraying, brushing, or dipping. Each method has advantages, and the choice depends on your working substrate.

7. Drying and Curing: The Crucial Steps

After applying the coating liquid, allow the substrate to dry thoroughly. Depending on the environment, this can take anywhere from 30 minutes to a few hours. Once dry, the substrate should be cured in an oven at a specific temperature and duration, as the coating manufacturer recommends.

8. Troubleshooting: Addressing Common Issues

Encountering challenges while making sublimation coating liquid is normal. If you face issues like streaking, uneven coating, or poor adhesion, consider adjusting your formulation, application technique, or curing process. Experimentation and learning from mistakes are part of the journey.

9. Experimentation and Innovation: Unleash Your Creativity

This type of printing opens the door to endless creative possibilities. Experiment with different formulations, substrates, and designs to find your unique style. Don’t hesitate to combine various additives or tweak proportions – innovation often stems from stepping beyond the conventional.

10. Embracing the Sublimation Revolution

By understanding the intricacies of crafting this vital solution, you embark on a journey that blends science with artistry, enabling you to transform ordinary objects into extraordinary works of visual delight.

Remember, the art of coating liquid is a continuous learning process. As you embark on your adventure, keep honing your skills, and never shy away from pushing boundaries. The world of sublimation printing eagerly awaits your imaginative touch!

Explore the world of sublimation and printers with our comprehensive guide, for more information or a step-by-step how-to guide.

In Conclusion

The journey of concocting your sublimation coating combines science, precision, and artistic flair. Armed with the knowledge of ingredients, proportions, and application techniques, you’re ready to dive into the world of sublimation printing.

As you craft your coating liquid and explore its potential, you’re not just making a liquid but preparing a gateway to a universe of creativity and expression. The magic of sublimation coating liquid is waiting for you to unlock it – so go ahead and make your mark!