Sublimation HTV: Print on Cotton, Dark Colors, and More

Sublimation HTV lets you apply full-color sublimation designs to cotton and dark-colored fabrics. It acts as a printable layer that bonds with sublimation ink, then adheres to materials that don’t usually support sublimation.

This method expands design options beyond polyester, making it ideal for cotton shirts, canvas bags, and dark garments with vibrant, lasting prints.

If you’re new to this, it helps to learn everything about sublimation printing first, since HTV works a bit differently from traditional polyester transfers.

What Is Sublimation HTV?

Sublimation HTV is a special type of heat‑transfer vinyl made to hold sublimation ink during printing. It creates a printable layer that bonds with the dye instead of the fabric itself.

During the process, sublimation dyes bond with the HTV layer, not directly with the garment. Then the HTV with the design adheres to the fabric under heat and pressure.

Benefits:

- Enables full‑color transfers on cotton garments.

- Works on dark-colored fabrics where traditional sublimation fails.

- Produces vibrant, long‑lasting prints wash after wash.

Types:

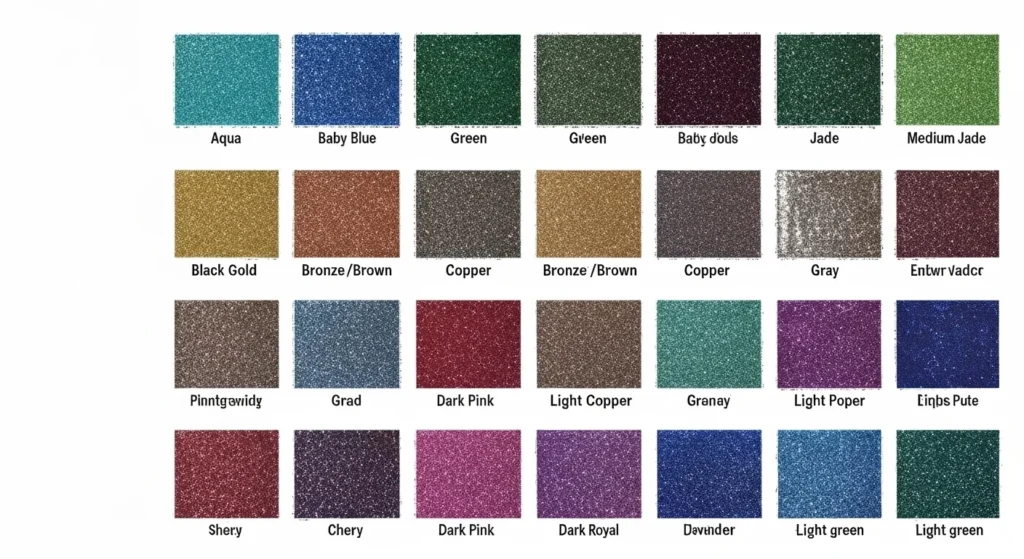

- Glitter HTV gives sparkle with good hold but feels stiff.

- EasySubli delivers soft, vibrant prints on various fabrics.

- Other clear or holographic HTV offer unique aesthetics, be cautious of adhesion texture and color shifts.

Glitter HTV is also fun to use for creative sublimation projects like holiday shirts, party bags, or standout gifts.

Glitter HTV

Special glitter HTV contains polyester, letting it hold sublimation ink. This creates vibrant, sparkly designs. Texture feels thicker and more rigid after press. Works best for bold, eye-catching prints.

Siser EasySubli

Designed specifically for sublimation, EasySubli is a soft vinyl that bonds exceptionally well with sublimation inks. It works on cotton, poly blends, and dark fabrics. Offers crisp photo-quality results with a smooth finish.

Other Compatible Brands

Clear Dye-Sub HTV, Siser Mystic White, Cricut Clear Dye-Sub and holographic HTV all support sublimation. These vary in feel (from ultra-thin clear to textured holographic) and may affect final color. Clear types blend with fabric; holographic adds shine.

🧠 Texture, Finish, Application Differences

| Brand / Type | Texture & Feel | Print Finish | Best Use Case |

|---|---|---|---|

| Glitter HTV | Thick, sparkly, firm | Shiny, metallic-sub base | Eye-catching designs |

| Siser EasySubli | Thin, smooth, flexible | Vibrant, photo-realistic | Soft feel on cotton or dark shirts |

| Clear Dye‑Sub / Mystic White / Cricut | Ultra-thin clear or holographic | Slightly altering tint or sheen | White or light cotton; decorative use |

Sublimation HTV vs Regular HTV

| Feature | Sublimation HTV | Regular HTV |

|---|---|---|

| Compatible with Ink | Sublimation ink only | Regular inks, no sublimation |

| Substrate Flexibility | Works on cotton, darks | Limited to basic vinyl designs |

| Print Quality | Full-color photo-realistic | Solid color or layered only |

Best Garments and Projects to Use

- Cotton shirts

- Tote bags

- Dark-colored apparel

- Towels and baby bibs

Learn how sublimation on cotton works using special HTV sheets in this detailed guide.

🧵 Siser® Heat Transfer Vinyl (HTV) Compatibility

| Product | Cotton | Polyester | Cotton/Poly Blends | Lycra/Spandex | Leather | Sublimated Polyester | Nylon | CPSIA Certified |

|---|---|---|---|---|---|---|---|---|

| EasyWeed® | ✅ | ✅ | ✅ | ✅ | ✅ | ✅ | ✅ | ✅ |

| EasyWeed® Extra | ✅ | ✅ | ✅ | ✅ | ✅ | ✅ | ✅ | ✅ |

| EasyWeed® Electric | ✅ | ✅ | ✅ | ✅ | ✅ | ✅ | ✅ | ✅ |

| EasyWeed® Stretch | ✅ | ✅ | ✅ | ✅ | ✅ | ✅ | ✅ | |

| EasyWeed® Sub Block | ✅ | ✅ | ✅ | ✅ | ||||

| Brick® 600 | ✅ | ✅ | ✅ | ✅ | ✅ | ✅ | ||

| StripFlock® Pro | ✅ | ✅ | ✅ | ✅ | ✅ | ✅ | ✅ | |

| Glitter | ✅ | ✅ | ✅ | ✅ | ✅ | ✅ | ||

| Holographic | ✅ | ✅ | ✅ | ✅ | ✅ | ✅ | ||

| EasyReflective® | ✅ | ✅ | ✅ | ✅ | ✅ | ✅ | ✅ | |

| Metal | ✅ | ✅ | ✅ | ✅ | ✅ | ✅ | ||

| Blackboard™ | ✅ | ✅ | ✅ | ✅ | ✅ | ✅ | ||

| EasySubli™ | ✅ | ✅ | ✅ | ✅ | ✅ | ✅ | ✅ | |

| EasyPatterns™ | ✅ | ✅ | ✅ | ✅ | ✅ | ✅ | ✅ | |

| EasyWeed® Adhesive | ✅ | ✅ | ✅ | ✅ | ✅ | ✅ | ✅ |

🏷️ Siser® EasyPSV® Adhesive Vinyl Compatibility

| Product | Ceramic | Drywall | Glass | Metal | Plastic | Wood |

|---|---|---|---|---|---|---|

| EasyPSV® Permanent | ✅ | ✅ | ✅ | ✅ | ✅ | ✅ |

| EasyPSV® Permanent-Glitter | ✅ | ✅ | ✅ | ✅ | ✅ | ✅ |

| EasyPSV® Removable | ✅ | ✅ | ✅ | ✅ | ✅ | ✅ |

⚠️ Not recommended for use in dishwashers or microwaves. Always test for compatibility before full application.

Top Brands

- HTVRONT Sublimation HTV, popular for cotton and dark garments. Known for wide color options and solid transfer quality.

- Siser EasySubli (and Mystic White/glitter options), holds vibrant inks and performs well on darker fabrics.

- Cricut + Clear Dye‑Sub HTV, high quality and tested performance; excellent creative versatility.

Brand Comparison & Press Settings

Siser EasySubli

- Press at 311 °F (155 °C) for 15 seconds, medium pressure, with silicone or parchment on top.

- Peel carrier hot, then place sublimation print and press again at 385 °F (196 °C) for 30–60 seconds, medium pressure.

HTVRONT Sublimation HTV

- Press HTV onto garment at 320 °F (160 °C) for 8–15 seconds, medium pressure, cool or warm peel

- Sublimate ink at 375–400 °F (190–205 °C) for 40–60 seconds, medium pressure, include tape and Teflon sheet.

Tips from Crafters

From feedback:

“Press at 315 °F for 15 seconds… then set heat press to 385 °F for 30 seconds” HTVRONT method mirrored in real-use workflows

Also:

“HTVRont should be pressed at like 305°. 315° is the maximum heat… press for 10‑15 seconds then peel about 30‑45 sec later”

Quick Reference Table

| Brand | Step | Temp | Time (sec) | Pressure | Peel Style |

|---|---|---|---|---|---|

| Siser EasySubli | Pre-press HTV | 311 °F | 15 | Medium | Hot peel |

| Sublimate transfer | 385 °F | 30–60 | Medium | Hot or warm peel | |

| HTVRONT | HTV adhesive press | 320 °F | 8–15 | Medium | Cool or warm |

| Ink sublimation press | 375–400 °F | 40–60 | Medium | Warm peel after |

Tips for Best Results

- Pre-press garments (3–5 sec) to remove moisture and lint.

- Use heat-resistant tape to avoid ink shift.

- Test on scrap fabric before full runs.

- If ink is faded or edges lift, repress for 10 seconds under same pressure.

Step‑by‑Step: How to Use Sublimation HTV

1. Design + Print

- Create your design, mirror it for cutting.

- Print using sublimation ink on sublimation paper (e.g., Epson EcoTank conversion).

2. Cut and Weed HTV

- Load HTV shiny side down, matte side up into cutter.

- Cut outline slightly smaller (e.g. 8″ to ~7.95″) to avoid white borders.

- Weed excess vinyl carefully.

3. Choose Sublimation Sequence

Two valid methods:

Method A: Press HTV first

- Press HTV onto fabric (e.g. 320 °F for 7–8 sec) — this secures placement.

- Lay sublimation print ink‑side down on HTV, secure with heat‑resistant tape.

- Press at 375–390 °F for ~30 sec under firm pressure. Use PTFE sheet or parchment to protect.

Method B: Sublimate HTV before pressing

- Peel HTV off carrier before use. Place adhesive side up directly on printed paper.

- Secure with tape, press at 375–390 °F for ~30 sec.

- Then press the pre‑sublimated HTV onto garment at ~320 °F for 12–15 sec.

4. Cool and Peel

- Let garment cool slightly before peeling paper/carrier.

- If edges lift, repress briefly (10 sec).

5. Final Care

- Let project rest 24 hours before washing.

- Wash inside‑out in cold water, air dry or low dryer heat.

- Avoid harsh detergents to preserve color and adhesion

Sublimation HTV for Light Fabric

Light-colored cotton blends work better than 100% cotton for durability. HTV isn’t just for dark shirts. You can use it on light cotton too, especially when you want vibrant colors on fabrics that don’t contain polyester.

Choose a smooth white HTV for best color clarity. Avoid transparent types unless layering on white garments.

Follow the same printing steps as dark fabric:

- Print your design (mirror on sublimation paper)

- Cut the HTV

- Press it onto the fabric

- Sublimate on top

For Cricut fans, using sublimation with Cricut brings even more flexibility for T-shirt projects and custom transfers.

HTVRONT Sublimation HTV Instructions

Always pre-press your fabric for 5 seconds to remove moisture. HTVRONT offers a budget-friendly sublimation HTV that works well for both beginners and pros.

It comes in white sheets that hold sublimation ink clearly and press cleanly onto cotton and dark fabrics.

Step-by-Step Instructions:

- Print Design – Use sublimation paper with mirrored artwork.

- Cut HTV – Load HTVRONT HTV into your cutter (Cricut/Silhouette).

- Weed It – Remove the excess vinyl.

- First Press – Apply HTV on the shirt at 310°F (155°C) for 10–15 seconds with medium pressure.

- Cool Peel – Let it cool down fully before peeling.

- Second Press – Place printed sublimation paper on top, then press at 380°F (193°C) for 30–40 seconds.

HTV Machine Compatibility

Just make sure your machine can reach at least 380°F (193°C) with firm, even pressure. Most craft cutting and heat press machines work with sublimation HTV. You don’t need special equipment beyond a standard setup.

Compatible Cutting Machines:

- Cricut Maker, Explore Air 2, Joy

- Silhouette Cameo 3, 4

- Brother ScanNCut

Compatible Heat Presses:

- Clamshell or swing-away models (manual or auto)

- Cricut EasyPress (works for small designs)

- HTVRONT Auto Heat Press

HTV Paper: What It Is and How It Works

Sublimation HTV paper isn’t a special kind of paper it’s standard sublimation paper used with sublimation-compatible HTV sheets. The paper holds the sublimation ink temporarily. Once heat-pressed over the HTV, the ink transfers and bonds to the HTV’s coating.

Key Points:

- Use high-quality sublimation paper (A-SUB, Koala, Hiipoo).

- Always print mirrored.

- Handle with dry hands to avoid smudges.

- Only works when pressed over sublimation HTV, not directly onto cotton.

This combo lets sublimation work on cotton, canvas, and dark colors.

Sublimation HTV for Light vs. Dark Fabrics

Sublimation HTV works on both light and dark garments, but the results differ based on fabric color. This method is ideal for cotton tees, canvas totes, and blended hoodies in any shade.

On Light Fabrics:

- Use white HTV (like Siser EasySubli or HTVRONT).

- Colors appear bright and true.

- Matte or glitter finishes both work well.

On Dark Fabrics:

- Always use white-backed HTV to block the garment color.

- Glitter HTV reflects light, helping colors pop.

- Avoid transparent or light HTV on dark shirts, it’ll mute the design.

Common Problems and Solutions

These solutions help maintain sharp, vibrant results and high adhesion on cotton or dark fabrics using.

Ghosting or blurry prints

Ghosting happens when the sublimation paper moves during heat pressing, producing a faint secondary design. Secure the paper with heat-resistant tape (or adhesive spray for fabric), press at correct temperature and pressure, and open the press slowly. Also pre-press fabric to remove moisture.

For More How I Found the Perfect Alternatives to Heat Tape for Sublimation.

HTV not adhering

HTV may not stick if time, temperature, or pressure settings are wrong. Make sure you apply firm, even pressure during HTV adherence step, then press sublimation ink at right heat duration. Test and adjust settings as needed.

Faded or dull colors

Faded results occur when ink density is wrong, ICC profile isn’t correct, or press temperature/time too low. Use high-quality sublimation ink and paper, correct color profile, and follow manufacturer heat settings for full ink activation.

Quick Fix Summary

| Problem | Cause | Fix |

|---|---|---|

| Ghosting / blurry image | Paper shifts or moisture | Secure paper; secure tape; pre-press fabric |

| HTV adhesion failure | Incorrect time/pressure | Increase or adjust heat and press time |

| Faded colors or weak prints | Ink/paper/profile issues | Use correct ICC, quality ink, proper settings |

Incorrect temperature or time can ruin a good transfer, so knowing the right sublimation temperatures is key for long-lasting results.