What is Sublimation Printing? Technology and its Applications

Sublimation printing is basically the secret sauce behind those bright shirts and super crisp custom mugs you see everywhere. The cool part is the ink sinks right into the material instead of sitting on top, so the colors pop and hang in there even after a ton of washes.

If you’ve ever wondered how people get edge to edge prints that look almost baked into the surface, this is the method doing all the magic. It’s simple once you see how it works, and it opens the door to all kinds of custom projects.

A sublimation printer uses heat to turn special ink into gas. This gas bonds with materials like polyester or polymer-coated surfaces. The result is a long-lasting, full-color design that won’t crack, peel, or fade.

Sublimation is a digital technology that transfers dye onto various materials using heat and pressure. Unlike traditional printing methods such as screen printing and offset printing, sublimation printing produces high-quality, photographic-quality images that are permanent and durable.

Sublimation Time, Temp and Pressure Guide

| Item | Temp | Time | Pressure |

|---|---|---|---|

| Shirts | 385°F | 45 seconds | Medium |

| Mugs | 400°F | 180 seconds | Firm |

| Tumblers | 400°F | 60 to 180 seconds | Firm |

| Metal panels | 385°F | 60 seconds | Light |

| Mousepads | 400°F | 40 seconds | Medium |

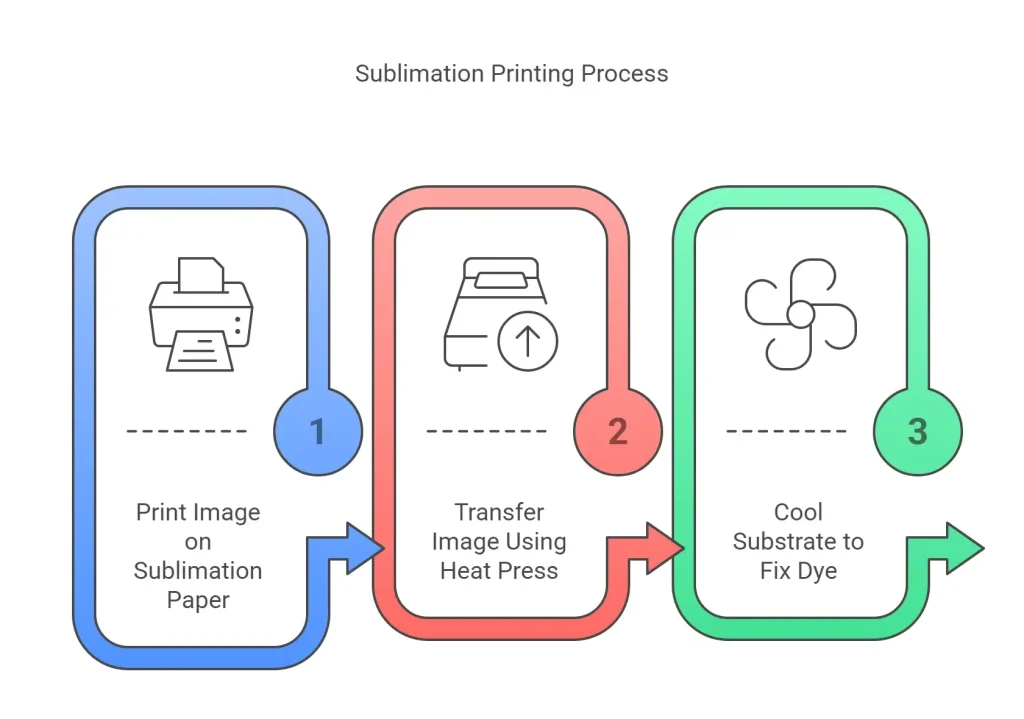

How does sublimation printing work?

Its works by turning solid dye particles into a gas that permeates the surface of the substrate, creating a permanent image. The process involves three steps: printing the image onto sublimation paper, transferring the image onto the substrate using a heat press, and cooling the substrate to fix the dye.

Sublimation ink usually bonds cleanly at around 380 to 400°F, which is why the heat press needs to hit those temps for a solid transfer.

Types of Sublimation Printing Techniques

As a sublimation researcher, I can explain the different printing methods. It is a popular digital technique that transfers dye onto various substrates, including textiles, ceramics, and metals. The dye process involves printing images onto special paper and then transferring the image onto the substrate using heat and pressure.

- Roll-to-roll sublimation:

- This type of printing involves using a large format sublimation printer to transfer images onto a continuous roll of sublimation paper. The paper is then fed through a heat press, which moves the image onto the substrate.

- Flatbed sublimation:

- Flatbed sublimation involves printing images onto a flat sheet of sublimation paper and then transferring the image onto a flat substrate, such as ceramic tiles, metal sheets, or wood panels.

- 3D sublimation:

- This technique transfers images onto three-dimensional objects, such as phone cases, mugs, or golf balls. The process involves using a special 3D sublimation vacuum press to transfer the image onto the curved or irregular surface of the object.

- Direct-to-textile sublimation:

- This method prints images directly onto fabric using a sublimation printer. The material is then passed through a heat press to transfer the image onto the textile.

The Benefits of Sublimation Printing

They offers several advantages over other printing methods, including:

- High-quality photographic images that are permanent and durable

- Ability to print on a wide range of materials, including textiles, ceramics, and metals

- No color limitations, as it can produce a full spectrum of colors.

- Low setup and production costs, making it ideal for small and medium-sized businesses

Most sublimated shirts stay bright for 50 plus wash cycles, which is way longer than vinyl or screen printing.

Equipment Needed for Sublimation Printing

To get started, you’ll need:

✅ Sublimation Printer (Epson, Sawgrass, or Ricoh models recommended)

✅ Sublimation Ink (Dye-based, not pigment ink)

✅ Heat Press (For flat or 3D substrates)

✅ Sublimation Paper (High-release for vibrant transfers)

✅ Polyester Fabric or Polymer-Coated Items (Cotton doesn’t work unless pretreated)

Advantages of Sublimation Printing

✔ Photographic Quality – Produces high-resolution, full-color prints.

✔ Durability – Won’t crack or fade, even after multiple washes.

✔ No Color Limits – Perfect for gradients and complex designs.

✔ Eco-Friendly – Less water waste than screen printing.

Disadvantages of Sublimation Printing

✖ Works Only on Polyester or Coated Surfaces – Not suitable for 100% cotton.

✖ Initial Cost – Requires specialized printers and inks.

✖ White Background Limitation – Can’t print white ink (relies on substrate color).

Applications of Sublimation Printing

The Future of Sublimation Printing

🔮 Eco-Friendly Inks – Water-based and biodegradable options in development.

🔮 Expanded Material Use – New coatings allow sublimation on wood, glass, and more.

🔮 AI Integration – Automated color correction and design optimization.

Sublimation printing vs. other printing technologies

| Feature | Sublimation | Screen Printing | DTG Printing |

|---|---|---|---|

| Durability | Excellent | Good | Moderate |

| Color Vibrancy | Best | Good | Good |

| Fabric Compatibility | Polyester only | All fabrics | Cotton/Poly blends |

| Cost for Small Runs | Affordable | Expensive setup | Moderate |

The sublimation industry is growing fast, expected to reach about $15 billion by 2030, thanks to demand for custom apparel and personalized products.

Setup and equipment

To get started with it, you’ll need a few pieces of equipment, including:

- Sublimation paper

- Sublimation ink cartridges

- A heat press

Substrate materials, such as textiles, ceramics, or metals

Sublimation Cost Breakdown

Sublimation is one of the most beginner friendly printing methods because the startup costs aren’t crazy and the cost per item stays low, even for small batches.

Startup Costs

- Printer 250 to 1500

- Heat press 150 to 800

- Sublimation paper 15 to 30 per pack

- Sublimation ink 20 to 100 per refill

These ranges shift a bit depending on the brand and if you grab an EcoTank style printer or a dedicated sublimation model.

Cost Per Item

- Shirt about 2 to 3 dollars

- Mug roughly 1 dollar for paper plus a 2 dollar blank

- Tumbler usually 3 to 5 dollars depending on size and coating

This is why so many small shops and creators love sublimation, you get pro quality results without spending a ton on each print.

Choosing the Right Sublimation Printer

Selecting the perfect sublimation printer requires careful consideration of these key factors:

Print Size

Consider the maximum print size required for your projects. Standard sizes range from 8.5″ for small items to 24″+ for large format printing on fabrics.

Print Quality

Look for printers with high resolution (minimum 300 dpi) and color accuracy to produce professional-grade photographic images.

Ink Type

Ensure compatibility with sublimation-specific inks and substrates. Some printers require conversion kits for optimal performance.

Cost Considerations

Factor in both the initial investment and ongoing costs (ink, paper, maintenance). EcoTank/MegaTank models often offer lower cost-per-print.

Pro Tip: Always check for warranty coverage and manufacturer support when investing in professional sublimation equipment.

Best practices for printing

- Use high-quality images with a minimum resolution of 300 DPI.

- Ensure that your substrate materials are clean and free of dust and debris.

- Use a heat press with accurate temperature and pressure settings.

- Allow the substrate to cool completely before handling it.

- Use high-quality sublimation ink and paper for the best results.

Common Sublimation Mistakes & How to Avoid Them

- Poor Color Output → Use ICC profiles for accurate color matching.

- Ghosting (Blurry Prints) → Ensure the paper doesn’t shift during pressing.

- Fading Prints → Use high-quality sublimation ink and proper heat settings.

- Fabric Scorching → Avoid excessive heat or pressing time.

Sublimation Printing and Sustainability

A more sustainable alternative to traditional printing methods like screen printing or direct-to-garment (DTG). But how eco-friendly is it really?

Why Sublimation Printing is Considered Sustainable

1. Less Water Waste

Unlike screen printing, which requires large amounts of water for cleaning screens and chemicals, sublimation uses dry heat transfer, eliminating water waste.

2. Minimal Chemical Use

- No harsh solvents or plastisol inks (common in screen printing).

- Sublimation inks are dye-based, reducing toxic runoff.

3. Reduced Fabric Waste

- Prints are permanent, meaning fewer misprints and reprints.

- No need for extra layers (like vinyl), which can peel and end up in landfills.

4. Energy Efficiency

- Modern sublimation printers and heat presses use energy-saving modes.

- Faster production = lower energy consumption per item.

Environmental Challenges of Sublimation

1. Polyester Dependency

- Sublimation only works on polyester or polymer-coated materials.

- Polyester is a petroleum-based synthetic fabric, contributing to microplastic pollution when washed.

✅ Solution: Use recycled polyester (rPET) to reduce environmental impact.

2. Ink and Paper Waste

- Sublimation requires special transfer paper, which isn’t always recyclable.

- Leftover ink cartridges can contribute to plastic waste.

✅ Solution: Opt for recyclable sublimation paper and refillable ink systems.

3. Energy Consumption

- Heat presses require high temperatures (350–400°F), increasing energy use.

✅ Solution: Use solar-powered or energy-efficient heat presses where possible.

Compares to Other Printing Methods

| Printing Method | Water Usage | Chemical Waste | Fabric Waste | Energy Use |

|---|---|---|---|---|

| Sublimation | Low | Low | Low | Medium |

| Screen Printing | High | High | Medium | Medium |

| DTG (Direct-to-Garment) | Medium | Medium | Medium | High |

| Vinyl Heat Transfer | Low | Medium | High | Medium |

How to Make Sublimation Printing More Sustainable

♻ Use Eco-Friendly Inks – Some brands offer water-based sublimation inks with fewer chemicals.

♻ Choose Recycled Polyester – Reduces reliance on new plastic-based fabrics.

♻ Optimize Heat Press Settings – Lower temps when possible to save energy.

♻ Recycle Transfer Paper – Look for compostable or recyclable options.

Sublimation Safety Tips

Sublimation is pretty safe, but the heat and fumes can still sneak up on you. A few simple habits keep your workspace comfortable and accident free.

Safety Basics

- Work in a ventilated area

Good airflow helps clear any light fumes from the heat press or freshly printed items. - Avoid inhaling fumes

The smell isn’t usually strong, but it’s still better not to breathe it in while things are heating. - Don’t touch freshly pressed items

Blanks come out extremely hot, especially metal panels, mugs, and tumblers. Give them a moment before handling. - Keep the heat press away from kids and pets

These machines run at 350 to 400 degrees, so you want them out of curious hands and paws.

A quick safety check before each session makes printing smoother and keeps your studio chill and hazard free.

Discover the Art of Sublimation Printing

Unlock your creative potential with professional sublimation techniques and printer insights.

Trusted by thousands of printing enthusiasts worldwide

30 Comments