Sublimation Sticker Paper Explained: Types, Benefits, and How to Choose

Sublimation sticker paper is designed to work with sublimation ink, creating durable, waterproof, and fade-resistant stickers. This guide explains how it works, the different types available, and how to choose the right one for your needs.

What is Sublimation Sticker Paper?

Sublimation stickers are an excellent choice for both personal and professional use due to their unique combination of durability, aesthetic appeal, and versatility.

Sublimation stickers are adhesive labels that use a dye-sublimation printing process. Heat and pressure are used to transfer dye onto materials, resulting in the ink turning into gas and bonding with the substrate.

A sticker that is both high-quality and durable and boasts vivid colors and intricate designs is the outcome. The sublimation process requires the use of polyester or polymer-coated materials, which are typically used to make these stickers.

In contrast to conventional stickers that can be printed using inkjet or laser, sublimation stickers possess superior print quality and longevity.

Key Benefits of Sublimation Sticker Paper

- Waterproof: Water resistance is achieved by creating a bond between the dye and the substrate through the sublimation process. Outdoor applications or items exposed to moisture benefit greatly from this feature.

- Fade-proof: Sublimation inks are more resistant to fading than other printing methods, ensuring that the stickers’ vibrant colors remain intact even when exposed to sunlight or harsh conditions.

- Vibrant Designs: A wide color gamut and intricate details can be achieved with the dye-sublimation technique, resulting in striking designs that stand out. The material is infused with the colors rather than printed on top, resulting in a more professional appearance.

Common Uses for Sublimation Sticker Paper

- Custom Decals: Ideal for personalizing items such as laptops, water bottles, and phone cases, sublimation stickers can be tailored to individual preferences.

- Crafts: Crafters often use sublimation stickers in scrapbooking, card making, and other creative projects due to their vibrant colors and durability.

- Professional Projects: Businesses utilize sublimation stickers for branding purposes, promotional materials, and product labeling. Their professional finish enhances brand visibility and appeal.

Unlike regular sticker paper, it is coated to accept sublimation ink, resulting in stickers that are not only waterproof and durable but also have a professional finish.

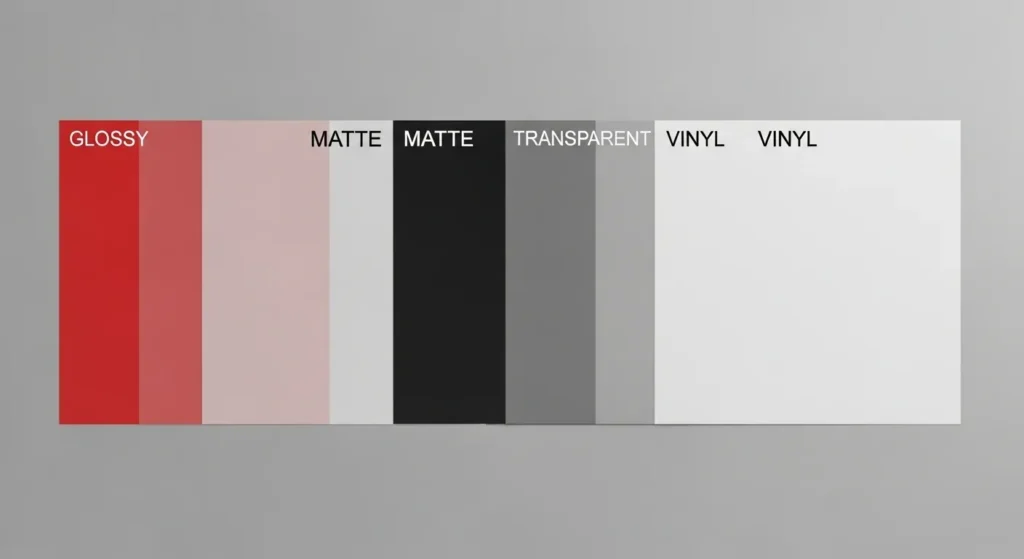

Types of Sticker Paper for Sublimation

1. Glossy Sticker Paper

Glossy sticker paper is a favorite among sublimation enthusiasts for its ability to produce vibrant, eye-catching prints. The glossy finish enhances the colors, making them pop and adding a professional sheen to your stickers.

This type of paper is perfect for decorative stickers, branding, and product labels that need to stand out. However, it’s worth noting that glossy sticker paper can be prone to smudging if not handled properly, so it’s important to allow your prints to dry completely before use.

2. Matte Sticker Paper

For those who prefer a more understated look, matte sticker paper offers an elegant solution. This type of paper absorbs ink well, resulting in detailed, soft-focus prints without the glare of a glossy finish. Matte stickers are ideal for vintage-inspired designs, informational labels, and products where readability is key.

Additionally, matte sticker paper is generally more resistant to fingerprints and smudges, making it a practical choice for items that will be handled frequently.

3. Transparent Sticker Paper

Transparent sticker paper allowing you to create custom stickers that blend seamlessly with the surface they’re applied to. This type of paper is perfect for intricate designs and logos, as it showcases the printed image without a visible background.

Transparent stickers are particularly popular for decorating glassware, windows, and tech devices, adding a personalized touch without obscuring the material beneath.

4. Vinyl Sticker Paper

Vinyl sticker paper is the go-to choice for outdoor and waterproof applications. Its durability and resistance to elements like water, UV rays, and extreme temperatures make it an excellent option for car decals, outdoor signage, and products that will be exposed to harsh conditions.

Vinyl stickers are also highly flexible, allowing them to adhere smoothly to curved surfaces.

|

Type of Sticker Paper |

Finish |

Durability |

Ideal Use |

|---|---|---|---|

|

Glossy Sticker Paper |

Glossy |

Moderate |

Decorative stickers, branding, and product labels |

|

Matte Sticker Paper |

Matte |

High |

Vintage designs, informational labels |

|

Transparent Sticker Paper |

Transparent |

Moderate to High |

Custom designs on glassware, windows, tech devices |

|

Vinyl Sticker Paper |

Various |

High |

Outdoor and waterproof applications |

Sublimation Sticker Paper vs Regular Sticker Paper

Sublimation sticker paper is designed to bond sublimation ink into a special coating using heat, creating stickers that are more durable, waterproof, and fade-resistant.

Regular sticker paper holds ink on the surface, which makes it easier to use but more prone to smudging, fading, and wear over time.

This difference is why sublimation sticker paper is preferred for long-lasting, professional-quality stickers.

In short, regular sticker paper works well for simple, short-term projects, while sublimation sticker paper is the better choice when durability, color vibrancy, and a professional finish matter.

Key Differences at a Glance

| Feature | Sublimation Sticker Paper | Regular Sticker Paper |

|---|---|---|

| Ink Type | Sublimation ink | Inkjet or laser ink |

| Color Durability | High, dye bonds with coating | Moderate, ink sits on surface |

| Water Resistance | Waterproof when properly applied | Limited water resistance |

| Fade Resistance | Better long-term color retention | More prone to fading |

| Best Use | Professional, long-lasting stickers | Everyday or short-term stickers |

How to Choose the Right Sublimation Sticker Paper

Choosing the right sublimation sticker paper depends on how your stickers will look, where they’ll be used, and what surface they’ll be applied to. Understanding these factors helps avoid dull colors, poor adhesion, or premature fading.

Choose Based on Finish

The finish affects both appearance and readability.

- Glossy sticker paper produces bright, high-contrast colors and a polished look, making it ideal for decorative stickers, branding, and product labels.

- Matte sticker paper offers a softer, glare-free finish that works well for text-heavy designs, vintage styles, or informational labels.

- Transparent sticker paper blends into the surface underneath, making it a good choice for logos, glass items, and minimalist designs.

Choose the finish that best matches the visual style and purpose of your stickers.

Choose Based on Durability

Durability matters, especially if your stickers will face moisture, handling, or outdoor conditions.

- For indoor use, most standard sublimation sticker papers provide sufficient water resistance and color stability.

- For outdoor or high-contact use, vinyl-based sublimation sticker paper offers better resistance to water, sunlight, and wear.

- If long-term color retention is important, look for papers designed for UV and fade resistance.

Higher durability papers are best for decals, equipment labels, and frequently handled items.

Choose Based on Application Surface

The surface you apply the sticker to plays a big role in performance.

- Smooth, flat surfaces like laptops, bottles, and packaging work well with most sublimation sticker papers.

- Curved or textured surfaces require more flexible materials, such as vinyl-based sticker paper, to prevent lifting or peeling.

- Glass and clear materials pair best with transparent sublimation sticker paper for a seamless appearance.

Matching the sticker paper to the application surface helps ensure proper adhesion and a clean finish.

🎨 Free Sublimation Sticker Designs (Download Pack)

To help you test and showcase sublimation sticker paper, we’ve added a small collection of ready-to-use sublimation sticker designs.

These designs are created to work well across glossy, matte, transparent, and vinyl sublimation sticker paper, so you can see how colors, details, and finishes behave on different materials.

The gallery above includes a mix of floral illustrations, abstract art, and illustrated scenes, making it easy to experiment with different visual styles before creating your own designs.

What’s included in the download

- 5 sublimation-ready sticker designs

- High-resolution PNG files (300 DPI)

- Transparent backgrounds where applicable

- Suitable for testing multiple sticker paper finishes

Are Sublimation Stickers Truly Waterproof and Fade-Proof?

Yes, sublimation stickers are waterproof and fade-resistant when printed on proper polyester or polymer-coated sticker paper. Because the dye bonds directly with the coating instead of sitting on top, the design becomes part of the material, resulting in better durability and longer-lasting color.

- Waterproof: Resistant to moisture and humidity without peeling or bleeding.

- Fade-resistant: Maintains color vibrancy longer than standard inkjet or laser stickers, even with sun exposure.

Further Reading

If you’re eager to learn more about sticker printing, get the right equipment and explore these informative resources.

- Discover the Best Printers for Vinyl Stickers to ensure your creations stand out with quality and durability.

- Find the perfect match for your sticker printing needs with our guide on the Best Printer for Stickers, tailored to help you make informed decisions for your projects.

Basic Equipment Used With Sublimation Sticker Paper

- Sublimation printer and ink

- Heat press

- Protective paper

- Heat-resistant tape

Frequently Asked Questions About Sublimation Sticker Paper

What is sublimation sticker paper?

Sublimation sticker paper is a specially coated adhesive paper designed to accept sublimation ink. When heat is applied, the ink bonds with the coating, creating durable, high-quality stickers.

Can you use regular sticker paper for sublimation?

No. Regular sticker paper does not have a polymer coating, so sublimation ink will not bond properly. This results in faded colors and poor durability.

What materials work best with sublimation sticker paper?

Sublimation sticker paper works best with polyester-based or polymer-coated surfaces. These materials allow the sublimation ink to bond correctly during heat transfer.

Are sublimation stickers waterproof?

Yes, sublimation stickers are water-resistant when printed on proper sublimation sticker paper. The dye becomes part of the coating rather than sitting on the surface.

Do sublimation stickers fade over time?

Sublimation stickers are more fade-resistant than standard inkjet stickers. While prolonged direct sunlight can cause gradual fading, they maintain color much longer under normal use.

Is sublimation sticker paper suitable for outdoor use?

Some sublimation sticker papers are suitable for outdoor use, especially vinyl-based options. For best results, additional protection like lamination may be recommended for long-term outdoor exposure.

Troubleshooting Common Issues

|

Problem |

Solution |

|---|---|

|

Color Not Transferring |

Ensure the paper is placed correctly and the heat is sufficient. |

|

Paper Jam |

Check printer compatibility and paper thickness. |

|

Fading Colors |

Use protective measures and correct storage practices. |

One Comment