Enhancing Results with UV Light for Sublimation

UV light is not used in sublimation printing. Sublimation relies on heat and pressure to turn solid dye into gas, which then bonds with polyester-coated surfaces.

UV printing, on the other hand, uses ultraviolet light to cure special inks. While both are popular in customization, they are entirely different processes with unique applications.

UV light can enhance the results of sublimation printing by curing the ink quickly and allowing immediate use of the finished product. This can save time and increase efficiency in the sublimation process.

What are the benefits of UV printing?

UV printing has several advantages over other types of printing. Some of the benefits of UV printing include:

- High-gloss finishes and vibrant colors → great for eye-catching designs.

- Instant curing with UV light → products are ready to handle right away.

- Works on almost any material → from plastics and glass to wood and metal.

- Special effects possible → like raised textures, spot gloss, or 3D finishes.

- Eco-friendlier process → no harmful solvents released into the air.

- Cost-effective for businesses → faster turnaround saves time and labor.

👉 Compared to traditional methods, UV printing reduces waiting time and expands creative options. For sublimation users, understanding UV printing helps identify when to combine it with sublimation for long-lasting results.

UV Light for Sublimation

If you work in the printing industry, you’ve probably heard people mention UV light alongside sublimation. While UV light is not part of the core sublimation process (which relies on heat and pressure), it can play a supporting role.

For example, applying a UV protective coating after sublimation and curing it with UV light helps improve product durability, especially for items exposed to sunlight.

The main benefits of adding UV protection to sublimated products include:

- Faster finishing times since coatings cure instantly under UV light.

- Brighter, more vibrant colors that resist fading.

- Longer durability outdoors, ideal for signage, apparel, and mugs.

- Efficient ink use by reducing reprints and extending product life.

- Sharper details because the coating locks in the print.

👉 In short, UV light doesn’t replace sublimation, it enhances it, especially when durability and outdoor use matter.

Introduction to UV Light

UV light is a type of electromagnetic radiation that is invisible to the naked eye. It has a shorter wavelength than visible light and is divided into three categories:

- UVA

- UVB

- UVC

While UV light is commonly associated with causing sunburns and skin damage, it also plays a crucial role in various processes on Earth.

UV Light and Its Properties

UV light, or ultraviolet radiation, is invisible electromagnetic energy. It has shorter wavelengths than visible light, typically ranging from 10 to 400 nanometers. UV light is divided into three categories based on its wavelength.

- UVA (315-400 nm)

- UVB (280-315 nm)

- UVC (100-280 nm)

How UV Light Affects Sublimation

The sublimation process is enhanced when UV light interacts with sublimation inks, as it triggers a photochemical reaction. The energy from UV light accelerates the sublimation process, causing the ink to transition from a solid to a gas state more efficiently. This leads to faster and more complete ink penetration into the material, resulting in sharper, more vibrant prints.

Understanding the Coating Process

When it comes to sublimation printing, the type of coating used plays a vital role in achieving optimal results. The coating acts as a medium to hold the sublimation ink and ensure proper transfer onto the material. Typically, a polyester-based coating is used for sublimation, as it has excellent compatibility with sublimation inks.

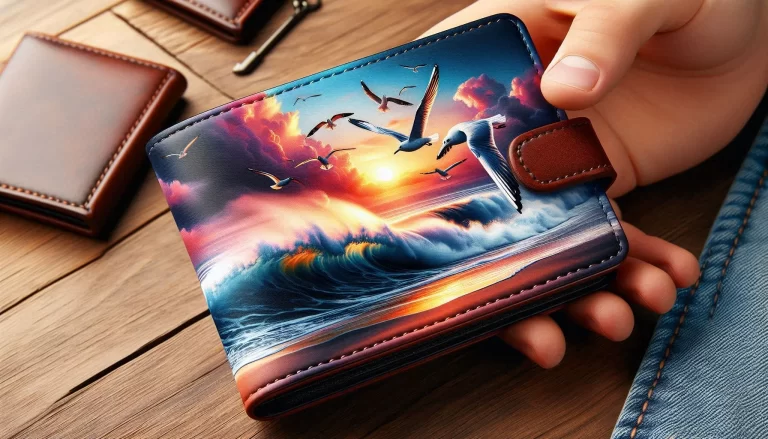

Unveiling UV Protective Coating

UV protective coating is a specialized layer applied to sublimated items to enhance their durability and resistance to fading caused by UV rays. The protective coating not only shields against harmful UV rays but also prolongs the durability of sublimated products, making them ideal for outdoor use, including signage, banners, and apparel.

Coating Techniques for Sublimation

To coat items for sublimation, there are multiple methods like spraying or dipping. Making workplace safety a top priority is essential, no matter which approach is selected.

To achieve this, close adherence to the instructions provided by the manufacturer and the provision of sufficient ventilation for a secure working environment are crucial.

How to Use UV Protection with Sublimation (Step-by-Step)

- Print your sublimation design using heat and pressure.

- Allow the item to cool before coating.

- Apply a UV protective spray or liquid coating.

- Cure the coating under UV light for long-lasting protection.

- Inspect the finished item for durability and gloss.

| Process | Uses Heat/Pressure? | Uses UV Light? | Best For | Durability |

|---|

| Sublimation | ✅ Yes | ❌ No | Polyester, coated blanks | High indoors |

| UV Printing | ❌ No | ✅ Yes | Hard surfaces, signage | High indoors/outdoors |

| Sublimation + UV | ✅ + ✅ | ✅ Protective | Outdoor products, apparel |

Cost & Time Insights

$ Cost Breakdown

💡 Adding UV coating increases total cost by 10-20% but significantly improves product durability.

⏱ Time Investment

📊 The minimal time investment pays off significantly by reducing returns and increasing customer satisfaction with longer-lasting products.

ROI Calculation

For just $0.40 and 3 minutes extra, you can potentially double the lifespan of outdoor sublimation products.

You can use our Sublimation Material and Product Selection Calculator for better estimate

Pros & Cons of UV Protection in Sublimation

Pros

- Extends print life for outdoor items

- Reduces fading from sunlight

- Enhances color vibrancy and gloss

- Adds durability to frequently used products (mugs, apparel)

- Relatively low cost per item

Cons

- Not part of the core sublimation process

- Adds extra time and production steps

- Requires proper UV light setup or coating products

- May not be necessary for indoor-only items

Quick Tips for Best Results with UV Protection in Sublimation

- Always let sublimated items cool before applying UV coatings.

- Use light, even layers when spraying coatings to avoid streaks.

- Follow manufacturer curing times for UV protection sprays or liquids.

- Test coatings on a sample item first before applying to bulk orders.

- For outdoor products, always add UV protection—it prevents fading and increases customer satisfaction.

Exploring Material Options

While polyester is the most popular material for sublimation printing due to its ability to hold sublimation ink effectively, other materials can also be used. Some examples include ceramic, metal, glass, and certain types of fabrics. It’s essential to consider the compatibility of the material with sublimation inks and ensure a suitable coating for optimal results.

The Role of Teflon in Sublimation

Teflon, a non-stick material, plays a significant role in sublimation printing. It is commonly used as a protective sheet or cover during the heat press process. Teflon sheets prevent sublimation ink from sticking to the heat press platen, reducing the risk of color transfer and ensuring clean, vibrant designs.

Sublimation Paper for Dark Shirts

When it comes to sublimating dark shirts, using a specific type of sublimation paper designed for dark fabrics is recommended. Unlike traditional sublimation paper, which requires a white or light-colored background, dark fabric sublimation paper has a unique coating that allows for vibrant and visible prints on dark garments.

Heat Transfer Paper on Dark Fabric

Using heat transfer paper on dark fabric is another effective method to achieve sublimation-like results. The process involves printing the design onto heat transfer paper with sublimation ink, followed by heat pressing the transfer paper onto the dark fabric. This technique allows for intricate designs and full-color prints on dark textiles.

🚀 Elevate Your Printing Game

Professional printing resources for stunning results

Make sure to review the subsequent articles to obtain additional details.

- Sublimation printer settings:

- How to print large sublimation images on Cricut:

- Heat press sublimation settings:

- How to convert an HP printer to a sublimation printer:

- Sublimation paper for large images on Cricut:

2 Comments