Sublimation Printing Basics: Master Tools, Materials, and Avoid Mistakes

Getting started with sublimation printing can feel overwhelming, especially if you’re new to the process. Whether you’re unsure about which printer to buy, struggling with how to transfer designs onto T-shirts, or simply confused about the materials needed, you’re not alone.

Many beginners face challenges like understanding how sublimation printing works, finding step-by-step guides, or troubleshooting common issues like faded prints or color mismatches.

But don’t worry—this guide is designed to walk you through sublimation printing basics in a clear and easy-to-follow way, offering insights and practical solutions to help you create vibrant, professional-quality prints from the start.

What Is Sublimation Printing?

Sublimation printing, a method used for transferring designs onto various surfaces, works by converting solid dye directly into gas through heat, skipping the liquid phase entirely. It’s often used on polyester fabrics and specially coated materials like mugs or keychains.

This technique ensures that the ink becomes part of the material itself, resulting in vivid, long-lasting prints that don’t fade or peel easily.

Why Choose Sublimation Over Other Methods?

Unlike screen printing or vinyl transfers, sublimation allows for detailed, full-color designs with no layering of inks or textures. It’s especially ideal for creating custom T-shirts, mugs, or even personalized phone cases.

The process works best on polyester fabrics and light-colored surfaces, which sets it apart from other methods that can work on a broader range of materials but may lack the same durability or quality.

Common Problems

One of the biggest challenges beginners face is confusion over the materials and equipment needed for sublimation printing.

People often wonder, “Can I use my regular printer for this?” or “Why can’t I sublimate on cotton shirts?” These kinds of questions lead to wasted time and materials when people use the wrong tools or surfaces.

Another common issue is figuring out the exact heat settings and pressure needed, which can vary depending on the material. Learning the ropes can feel like pulling teeth, but once the basics are understood, the process becomes much smoother.

How Does Sublimation Printing Work?

Step-by-Step Breakdown of the Sublimation Process

Sublimation printing is a straightforward process when broken down into simple steps. First, you need a special printer loaded with sublimation ink.

This ink is designed to turn into a gas when heated. Next, the design is printed onto sublimation paper, which holds the ink until it’s transferred. Then, you place the printed paper onto your blank item, such as a polyester T-shirt or a coated mug.

Using a heat press, you apply high heat and pressure, causing the ink to convert from a solid into a gas, bonding it with the fibers or surface of the material. Once the press is lifted, you peel off the paper, and the design is permanently embedded into the product.

Key Concepts: The Science Behind Sublimation

- Heat: Converts solid ink into gas, essential for the sublimation process.

- Pressure: Ensures even transfer of the design onto the item.

- Sublimation Paper: Holds the ink and releases it during the heat press process.

| Element | Function |

|---|---|

| Sublimation Ink | Turns into gas under heat, bonding to surfaces |

| Sublimation Paper | Transfers the ink to the item |

| Heat Press | Provides the necessary heat and pressure |

Common Problems

- Material Compatibility: Sublimation only works on polyester or specially coated surfaces.

- Wrong Materials: Regular ink or paper won’t work; you need sublimation-specific materials.

- Incorrect Heat or Pressure: Too much or too little can cause fading or incomplete transfers.

Sublimation Blanks

What materials can be sublimated?

- Sublimation only works on polyester fabrics and specially coated surfaces like mugs, keychains, and phone cases. Cotton or untreated surfaces won’t hold the design properly.

| Material | Compatibility with Sublimation |

|---|---|

| Polyester T-shirts | Excellent |

| Coated Mugs | Great for detailed designs |

| Cotton T-shirts | Not suitable for sublimation |

| Keychains, Phone Cases | Good if coated for sublimation |

Common Problems

- Finding Compatible Printers: Many beginners struggle to find printers that can handle sublimation ink.

- Choosing the Right Heat Press: New users often get overwhelmed by the variety of heat presses available.

- Using the Wrong Materials: Trying to sublimate on cotton shirts or dark-colored surfaces leads to poor results.

Sublimation vs. Other Printing Methods

Sublimation vs. Screen Printing

How do these two methods differ in terms of application and materials?

- Sublimation: Uses heat to bond dye directly into polyester or coated materials. Ideal for high-detail, full-color designs and smaller, custom projects like T-shirts and mugs.

- Screen Printing: Applies layers of ink through a mesh screen onto various materials, including cotton. It’s more suited for larger batches of items with fewer colors.

| Method | Best For | Materials |

|---|---|---|

| Sublimation | Small, custom projects with detail | Polyester, coated surfaces |

| Screen Printing | Large batches with simple designs | Cotton, mixed fabrics |

Sublimation vs. Heat Transfer Vinyl (HTV / Iron-On)

Which method should you choose for your project?

- Sublimation: Best for intricate designs that need full color and gradient effects, but only works on light polyester fabrics or coated surfaces.

- HTV/Iron-On: Heat transfers vinyl cut-outs onto various materials, including cotton. It works well for simple designs but doesn’t offer the same smooth, dye-embedded finish as sublimation.

| Method | Best For | Materials |

|---|---|---|

| Sublimation | Full-color, intricate designs | Polyester, coated items |

| HTV/Iron-On | Simple, bold designs | Cotton, polyester, mixed fabrics |

Sublimation vs. Cricut Infusible Ink

How are these two methods similar, and when should you opt for one over the other?

- Sublimation and Cricut Infusible Ink both use heat to permanently transfer designs into the material, rather than just placing them on the surface. However, Cricut Infusible Ink is limited to Cricut-brand products and tools, while sublimation offers more flexibility in design and material options.

| Method | Best For | Tools Needed |

|---|---|---|

| Sublimation | Flexible projects with custom designs | Sublimation printer, heat press |

| Cricut Infusible Ink | Pre-designed projects with Cricut | Cricut machine, Infusible Ink |

Common Problems

- Mixing Up Methods: Beginners often confuse sublimation with screen printing or HTV, which leads to choosing the wrong process and wasting time or materials.

- Incompatible Materials: Users frequently try to use sublimation on cotton, or screen printing on complex designs, leading to poor results.

Sublimation Printing for Beginners

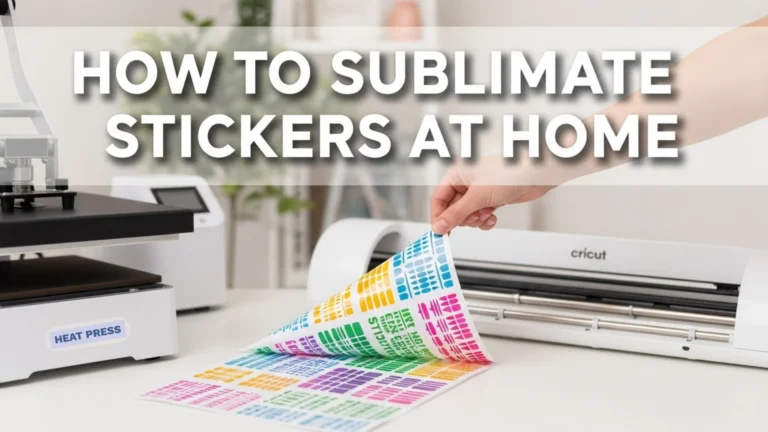

Print: Preparing Your Design for Sublimation

- Choose the right design software: Programs like Adobe Illustrator or Photoshop are great for creating detailed designs. Make sure your design is in high resolution to avoid pixelation.

- Mirror your image: Always flip your design horizontally before printing. This ensures that it transfers correctly when pressed onto the material.

- Use sublimation paper: Print your design on sublimation paper using sublimation ink. Regular paper or ink won’t work for this process.

Prepare: Getting Your Materials Ready

- Select the right blank: Use polyester-based items like T-shirts, mugs, or specially coated materials. Avoid cotton fabrics, as they don’t bond with sublimation ink.

- Preheat your heat press: Set the temperature and time according to the material. Typically, it’s between 350°F and 400°F, depending on the substrate.

- Place your design: Align the printed sublimation paper on the blank item with the printed side facing the surface.

Press: Applying Heat and Pressure Correctly

- Apply consistent pressure: Close the heat press and apply firm pressure for the set time. This ensures that the design transfers evenly.

- Remove the paper: After pressing, carefully peel off the sublimation paper to reveal the transferred design. Allow the item to cool down.

Common Problems

- Inaccurate Heat Settings: Too much or too little heat can result in faded or incomplete designs. Always check the recommended temperature for your blanks.

- Poor Material Prep: Skipping pre-pressing or not aligning the design properly can lead to uneven transfers or ghosting effects.

What Can You Sublimate On?

Types of Substrates for Sublimation

Sublimation works best on polyester fabrics and specially coated items. Some common substrates include:

- Polyester Garments: T-shirts, hoodies, and other polyester-based clothing items.

- Mugs: Ceramic or metal mugs with a sublimation coating.

- Metal: Coated metal plates, photo panels, or keychains.

- Phone Cases & Keychains: Specially coated for sublimation printing.

| Substrate | Compatibility |

|---|---|

| Polyester Clothing | Ideal for vibrant, lasting designs |

| Coated Mugs | Great for detailed images and logos |

| Metal Panels | Excellent for photo printing |

Can You Sublimate on Cotton or Regular Coffee Mugs?

No, sublimation does not work on cotton fabrics or regular, uncoated coffee mugs. Cotton lacks the necessary polymer coating for the ink to bond, causing the design to fade or wash out quickly. Similarly, regular mugs that aren’t coated for sublimation will not retain the design, and it may peel off after washing.

What Colors Work Best for Sublimation?

Sublimation printing works best on white or light-colored materials. The ink is transparent, so it blends with the surface color. Dark or black substrates will obscure the design. For vibrant and true-to-color results, stick to light shades, especially when working with fabrics.

| Material Color | Result |

|---|---|

| White/Light Colors | Best for bright and clear designs |

| Dark Colors | Design may not show properly |

Common Problems

- Using Cotton or Uncoated Surfaces: This leads to poor-quality designs that fade or wash out quickly.

- Sublimating on Dark Colors: The design becomes nearly invisible or distorted when applied to dark or black items.

Sublimation Printing Cost

How Much Does It Cost to Get Started?

Sublimation printing has a higher upfront cost compared to other printing methods due to the specialized equipment required. Here’s a breakdown of the average costs:

- Sublimation Printer: $250 – $600 (depending on the brand and model)

- Heat Press: $200 – $500 (prices vary based on size and type)

- Sublimation Ink: $50 – $100 per set

- Sublimation Paper: $20 – $50 per pack

- Blanks (T-shirts, mugs, etc.): $2 – $10 per item depending on the material

| Item | Estimated Cost |

|---|---|

| Sublimation Printer | $250 – $600 |

| Heat Press | $200 – $500 |

| Sublimation Ink | $50 – $100 |

| Sublimation Paper | $20 – $50 |

| Blanks | $2 – $10 per item |

Common Problems

- High Upfront Costs: The initial investment in equipment can be daunting for beginners.

- Purchasing the Wrong Equipment: Many first-timers buy the wrong printer or heat press, leading to poor-quality results or wasted money. Check out our cost calculator app

Troubleshooting Common Sublimation Issues

Common Problems and Solutions

Why Isn’t My Design Transferring Properly?

- Cause: Incorrect heat, time, or pressure settings.

- Solution: Ensure the heat press is set to the correct temperature (usually between 350°F and 400°F) and that pressure is evenly distributed. Adjust press time based on the material.

Why Is My Sublimation Paper Sticking?

- Cause: Overheating or excessive pressure.

- Solution: Reduce the temperature and check that your press time aligns with the substrate’s requirements. Also, use protective sheets to prevent sticking.

Why Are Small Dots Appearing on My Design?

- Cause: Moisture on the paper or substrate.

- Solution: Pre-press the item for a few seconds to remove moisture, and store sublimation paper in a dry, cool place.

Why Does My Design Crack or Fade After Washing?

- Cause: Incorrect substrate or improper wash care.

- Solution: Use polyester-based materials only. Ensure garments are washed inside and out in cold water to preserve the design’s quality.

Common Problems

- Fading or Cracking: Caused by poor-quality blanks or washing the item incorrectly.

- Dots on the Design: Often the result of moisture during the printing process.

- Paper Sticking: Typically due to too much heat or pressure applied during pressing.

5 Essential Sublimation Tips for Beginners

- Optimize Your Design

- Make sure your design is high resolution (300 dpi or higher) to avoid pixelation. Always mirror the design before printing to ensure it transfers correctly onto the substrate.

- Choose the Right Blanks

- Use only polyester fabrics or sublimation-coated items like mugs and keychains. Avoid cotton or untreated surfaces, as they won’t hold the ink properly.

- Set Your Heat Press Correctly

- Adjust the temperature, time, and pressure based on the material you’re working with. Most sublimation projects require temperatures between 350°F and 400°F, with medium pressure.

- Pre-Press Your Blank

- Always pre-press your garment or item for a few seconds to remove any moisture or wrinkles before applying the sublimation paper.

- Test First

- Do a small test run before starting large batches. This will help you fine-tune the heat settings and ensure the design transfers properly.

Common Problems

- Overlooking Design Resolution: Low-resolution images lead to blurry or pixelated prints.

- Using the Wrong Materials: Beginners often try sublimating on cotton or dark fabrics, resulting in poor-quality designs.

- Incorrect Heat Settings: Using the wrong temperature or not pre-pressing the blank can lead to incomplete transfers or fading. Check out the printing setting.

FAQs for Beginners

Can I Use My Regular Inkjet Printer for Sublimation?

Answer: No, a regular inkjet printer won’t work for sublimation unless it’s specifically converted for this purpose. You need a printer that is compatible with sublimation ink, like certain models from Epson or Sawgrass.

Do I Need a Cricut Machine for Sublimation?

Answer: No, a Cricut machine is not necessary for sublimation. While Cricut can be used for vinyl cutting, sublimation requires only a sublimation printer, heat press, and the right materials. However, Cricut Infusible Ink is a similar process designed for Cricut users.

Where Can I Find Designs for Sublimation Projects?

Answer: You can create your own designs using software like Adobe Illustrator or Canva, or purchase ready-made designs from websites like Etsy, Creative Market, or designbundles.net. Many websites also offer free design templates.

What are the advantages of sublimation printing? The advantages of sublimation printing include high-quality and long-lasting prints and the ability to print on various items.

Check out Benefits of Sublimation Printing: The Magic of Colors.

Tips for Successful Sublimation

For successful sublimation printing, it’s essential to properly store the sublimation ink, adjust the heat press temperature and time, and choose the right transfer paper. Following these tips will result in high-quality and long-lasting prints.

For more reading about Sublimation Printing, or more about Buyer Guide.

2 Comments