How I Choose the Best Sublimation Blanks and Substrates

Sublimation may seem daunting at first, but with the right knowledge and resources, it becomes much easier to manage. In Subli Genius Print, we have found that understanding the types of blanks available, choosing the right substrate for your project, and following best practices is essential for achieving impressive results in sublimation printing.

- Polyester fabrics = Yes

- Cotton = No (unless pre-treated or blended)

- Coated hard surfaces = Yes (ceramic, aluminum, MDF, glass)

Choosing quality materials, finding reliable suppliers, and implementing effective techniques are all crucial steps in ensuring your prints turn out beautifully.

Finding the right blanks and substrates felt overwhelming when I started with sublimation printing. With so many options, knowing where to start and what to choose was tricky. Over time, I’ve learned much about what works best for different projects.

In this guide, I’ll share my personal experiences and tips to help you make informed decisions.

What Are Sublimation Blanks and Substrates?

The terms sublimation blanks and substrates are often used, but they can be a bit confusing at first. Here’s a quick rundown based on what I’ve learned from my own experience:

- Sublimation Blanks: These are the items that will be printed on. A special polymer is pre-coated on them, allowing the sublimation ink to bond with the surface. Mugs, T-shirts, phone cases, and plaques are all common blanks. Proper coating is necessary to hold the ink and produce vibrant, lasting prints.

- Substrates: The materials used for sublimation printing are known as this term. Substrates can be broadly defined as any material that can absorb sublimation ink, even though they often overlap with blanks. Ceramic tiles, metal sheets, and polyester fabrics are all types of substrates used in sublimating.

For sublimation to work, the surface must be polyester-based or polymer-coated. Cotton and uncoated materials won’t bond with sublimation ink, no matter how long you press. Always check that your blanks are labeled “sublimation-ready” and pre-press them to remove moisture before transferring.

Types of Sublimation Blanks

Choosing the right blank is essential for getting the best results regarding sublimation printing. Here’s a look at some popular types of sublimation blanks I’ve found to be especially useful:

1. Mugs

- Material: Typically ceramic with a special polymer coating.

- Uses: Great for personalized gifts or promotional items.

- Tips: Ensure the mug has a smooth coating for vibrant and durable prints.

2. T-Shirts and Apparel

- Material: Polyester fabrics or cotton/polyester blends with a sublimation coating.

- Uses: Perfect for custom designs and team uniforms.

- Tips: Higher polyester content ensures better color vibrancy and durability.

3. Phone Cases

- Material: Hard plastic or rubber with a sublimation coating.

- Uses: Popular for custom phone accessories.

- Tips: Ensure the phone case fits well with your printing equipment for accurate alignment.

4. Keychains

- Material: Metal or acrylic with a coating for sublimation.

- Uses: Ideal for small, personalized items or promotional giveaways.

- Tips: Small sizes can make printing details more challenging, so choose high-quality blanks.

5. Coasters

- Material: Ceramic, cork, or MDF with a sublimation coating.

- Uses: Useful for home décor or promotional products.

- Tips: Ensure the coating is uniform to avoid any inconsistencies in the print.

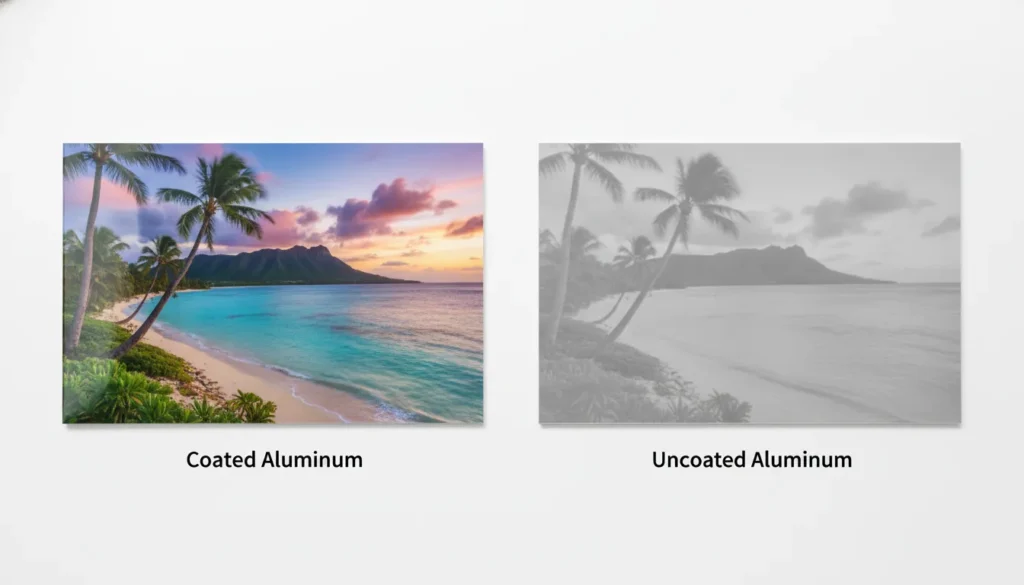

6. Aluminum Plates

- Material: Aluminum sheets with a special sublimation coating.

- Uses: Excellent for plaques, awards, or decorative signs.

- Tips: Check for any imperfections in the coating to ensure a smooth print.

7. Glassware

- Material: Glass with a sublimation coating.

- Uses: Ideal for custom drinkware and gifts.

- Tips: Handle carefully to avoid scratches on the coating before printing.

Each type of blank offers unique possibilities, so choosing the right one depends on your project’s needs and desired outcome. Experimenting with different blanks can help you discover which works best for your sublimation printing projects.

Check Can You Sublimate on Different Materials? Guide for Silicone, Plastic, Wood, Glass, Metal, and More

Know What Works with Sublimation

Sublimation only bonds with polyester or polymer-coated surfaces.

In short:

- Polyester fabrics = Yes

- Cotton = No (unless pre-treated or blended)

- Coated hard surfaces = Yes (ceramic, aluminum, MDF, glass)

Choosing the Right Substrate for Your Project

For long-lasting, vibrant sublimation prints, always choose blanks with a polymer coating and high polyester content. Avoid untreated cotton or uncoated materials, since they can’t bond properly with sublimation ink.

| Substrate Type | Works with Sublimation | Finish Options | Ideal Use |

|---|

| Polyester Fabric | ✅ Excellent | Matte / Glossy | Apparel, flags, tote bags |

| Coated Ceramic | ✅ Excellent | Glossy | Mugs, tiles, coasters |

| Aluminum Panels | ✅ Excellent | Glossy / Brushed | Photo panels, plaques |

| Glass (Coated) | ✅ Good | Glossy | Awards, decorative gifts |

| Cotton (Uncoated) | ❌ Not Suitable | – | Not recommended |

1. Material Compatibility

Ink and Printer Types:

Not every material works with sublimation. Always confirm that your substrate matches your printer and ink type. Use sublimation-specific materials to ensure the ink vapor bonds to the surface.

Polyester vs. Coated Materials:

- Polyester fabrics deliver vibrant, consistent colors.

- Coated hard surfaces (like aluminum, ceramic, or glass) must have a sublimation-ready polymer coating for proper adhesion.

Pro Tip: Use at least 65% polyester content for apparel to ensure lasting color retention.

2. Durability and Finish

Print Longevity:

Higher-quality coatings or base materials last longer and resist fading. Substrates with premium coatings tend to maintain their color vibrancy even after repeated washing or UV exposure.

Finish Options:

Choose between glossy, matte, or textured finishes based on your desired look. Glossy surfaces enhance color depth, while matte finishes reduce glare and fingerprints.

3. Project-Specific Tips

Personal Projects:

Match the substrate with your design’s purpose.

- Ceramic mugs: Great for everyday use or gifts.

- Metal plates: Perfect for awards or memorial prints.

Commercial Use:

When producing items for resale or promotions, balance cost and quality. Pick substrates that align with your brand’s image and can be reproduced consistently.

4. Cost vs. Quality

Budget Considerations:

High-quality blanks often cost more upfront but deliver better color, adhesion, and longevity. Think of them as an investment in fewer reprints and happier clients.

Bulk Purchasing:

Buying in bulk can lower costs, but always test a sample first to confirm coating quality and ink compatibility.

5. Sample Testing

Before ordering large quantities, test print a sample.

This simple step helps confirm:

✅ Proper ink bonding

✅ Color vibrancy

✅ Surface consistency

Pro Tip: Keep a record of each substrate’s temperature, time, and pressure settings for future reference.

Check out the Sublimation Material and Product Selection Calculator.

Comparison Guide: Polyester vs. Cotton and Coated vs. Uncoated Surfaces

When you’re deciding which materials to use for sublimation, the key factor is how well the surface can bond with sublimation ink. The tables below break it down so you can instantly see what works and what doesn’t.

Polyester vs. Cotton in Sublimation Printing

| Feature | Polyester (Recommended) | Cotton (Not Ideal) |

|---|---|---|

| Ink Bonding | Excellent – dye gas bonds permanently with polyester fibers | Poor – fibers don’t absorb sublimation ink |

| Color Vibrancy | Bright, vivid colors that last through washes | Dull or faded colors without pretreatment |

| Durability | Long-lasting and resistant to cracking or peeling | Print washes out quickly |

| Feel & Finish | Smooth and consistent surface for detailed designs | Softer texture but weak ink adhesion |

| Ideal Use | Apparel, flags, sportswear, pillowcases, tote bags | Only when pre-treated or blended (at least 65% polyester) |

| Cost | Slightly higher, but more reliable for sublimation | Lower, but requires added pretreatment cost |

| Pro Tip | Choose 100% polyester for the best, most durable prints | Use a poly-blend or poly coating spray for partial success |

Coated vs. Uncoated Hard Surfaces

| Feature | Coated (Polymer/Poly-Coated) | Uncoated (Raw Surface) |

|---|---|---|

| Ink Transfer | Bonds perfectly with heat and pressure | Ink doesn’t adhere or vaporize correctly |

| Color Vibrancy | Produces bright, accurate, long-lasting prints | Faded, patchy, or non-transfer results |

| Durability | Scratch-resistant and dishwasher-safe when done right | Easily damaged, wears off quickly |

| Suitable Materials | Ceramic mugs, aluminum panels, glass, MDF boards | Raw wood, uncoated ceramics, untreated metal |

| Maintenance | Easy to clean, resists fading | Color peels or fades with moisture or use |

| Ideal For | Professional-grade sublimation products | DIY tests only (not for resale) |

| Pro Tip | Look for labels like “sublimation-ready” or “poly-coated” | Avoid unless you plan to apply a sublimation coating manually |

- Sublimation only works on polyester fabrics or coated surfaces because the ink turns into gas and chemically bonds with those materials.

- Cotton and uncoated surfaces can’t hold the ink, leading to dull or faded results.

- When in doubt, check for “sublimation-ready” tags before pressing.

Real-World Case Studies: Sublimation Blanks That Made a Difference

Seeing real examples of what works (and what doesn’t) can make choosing blanks much easier. Here are a couple of stories from real-world printing situations that highlight how the right materials can completely change your results.

Case Study 1: How Switching to ChromaLuxe Panels Boosted Durability and Color Depth

One of our small business clients, a local photography studio, was struggling with dull, faded metal prints. They were using generic aluminum panels from an online seller. The images looked fine at first but started fading within a few months, especially when exposed to sunlight.

We recommended switching to ChromaLuxe sublimation panels, known for their premium polymer coating. After making the change:

- Color vibrancy improved by 40%, especially in skin tones and dark gradients.

- Surface durability increased, with no visible fading after 6 months of display.

- Customer satisfaction scores rose because the prints matched their digital previews.

Investing in higher-grade coated substrates can dramatically improve both the appearance and longevity of your sublimation prints, especially for commercial or gallery-quality products.

Case Study 2: The Mug Coating Fix That Saved a Product Line

A small eCommerce brand selling custom mugs contacted us about ghosting and color distortion issues. Their black prints were coming out brownish, and many designs looked patchy after washing.

We tested their blanks and discovered inconsistent polymer coatings on their mugs. We replaced them with heat-tested, poly-coated mugs from a verified supplier. After one production run:

- Print reject rate dropped from 18% to under 3%.

- Dishwasher resistance improved by 50%, based on client testing.

- The business reported a 20% increase in repeat orders within two months.

Reliable suppliers and uniform coatings make a massive difference in long-term quality control. A small change in substrate source can cut waste, save ink, and boost customer trust.

Case Study 3: Polyester vs. Cotton: The Apparel Experiment

We ran a side-by-side comparison of 100% polyester shirts and cotton/poly blend shirts for a local event order. The goal was to see how each handled the same design under identical conditions.

- Polyester shirts: Crisp edges, vivid reds, and zero fading after 10 washes.

- Cotton blends (50/50): Muted colors, visible fading after 3 washes, and patchy transfer zones.

Result: 100% polyester shirts retained 95% of original color intensity after multiple washes, while cotton blends dropped to around 60%.

Where to Buy Sublimation Blanks and Substrates

Finding the right place to purchase is as important as selecting the right materials. Based on my own experiences, here are some tips to help you locate the best sources:

1. Top Retailers and Suppliers

- Specialty Sublimation Stores: These stores focus on sublimation supplies and often offer various blanks and substrates. They may also provide valuable expertise and customer support.

- Online Marketplaces: Websites like Amazon and eBay have a variety of sublimation blanks and substrates. Check reviews and ratings to ensure you’re buying from reputable sellers.

- Direct from Manufacturers: Some manufacturers sell directly to customers, sometimes resulting in better prices or access to exclusive products.

2. Online vs. Local Stores

- Online Advantages: Shopping online provides access to a broader range of products and often better prices due to lower overhead costs. It’s convenient and allows you to compare options easily.

- Local Stores Benefits: Visiting local stores lets you inspect the blanks and substrates in person before buying. It can also be quicker if you need something immediately, allowing you to build relationships with local suppliers.

3. Price Comparison

- Finding Deals: Look for discounts, bulk purchase deals, or seasonal sales. Some suppliers offer better pricing if you buy in larger quantities or sign up for their mailing list.

- Quality vs. Cost: While choosing the cheapest option is tempting, remember that quality often impacts the final result. Invest in good-quality blanks and substrates to ensure your prints look great and last long.

4. Supplier Recommendations

- Ask for Recommendations: Don’t hesitate to ask other sublimation enthusiasts or professionals for their preferred suppliers. Their experiences can provide valuable insights and help you find reliable sources.

- Check for Reviews: Look for reviews and testimonials about the suppliers you’re considering. This can give you an idea of their customer service, product quality, and shipping reliability.

5. Shipping and Returns

- Shipping Policies: Check the shipping costs and delivery times. Some suppliers offer free shipping for orders over a certain amount, which can be a great way to save.

- Return Policies: Understand the return policy if you receive defective or incorrect items. It’s important to have the option to return or exchange products.

The Substrate Compatibility Checker Calculator for Sublimation

Sublimation Blanks Distributors

Unisub: A leading manufacturer of high-quality sublimation blanks, offering a wide range of products made in the USA. Their items are designed for vibrant, full-color printing, suitable for various applications. You can find their products through authorized distributors nationwide.

Heat Transfer Warehouse: Provides a diverse selection of dye sublimation blanks, including patches, keychains, photo panels, koozies, mouse pads, license plates, and Polar Camel mugs. They offer products from brands like Unisub, Chromaluxe, SubliCraft, and more.

Pro World: With over 40 product categories, Pro World offers a vast selection of sublimation blanks such as face masks, fabrics, tumblers, socks, outerwear, hoodies, coasters, bottles, puzzles, pillowcases, keychains, and license plates. They are known for their quality products and excellent customer service.

INNOSUB USA: Specializes in manufacturing high-quality sublimation blanks, including phone cases, tumblers, kids’ bags, dog tags, AirPods cases, and linen items. They offer fast shipping from Los Angeles and provide 24/7 support.

Technotape: Offers high-quality sublimation blanks tailored for reliable results, including ChromaLuxe products and S-Race sublimation paper. Their products are designed for versatile use, providing vibrant colors and consistent quality.

Best Practices for Using Blanks and Substrates

Getting the most out of your projects involves more than choosing the right products. Based on my own experiences, here are some best practices to follow for optimal results:

1. Preparation Tips

- Surface Cleaning: Before printing, ensure the substrate’s surface is clean and free of dust or oils. For fabrics, ensure they are pre-washed to remove any residues.

- Proper Coating: For blanks that require a specific coating, ensure it’s applied evenly and according to the manufacturer’s instructions. This is crucial for achieving high-quality prints.

2. Application Techniques

- Temperature and Pressure: Follow the recommended temperature and pressure settings for your sublimation printer and heat press. These settings can vary depending on the type of substrate you’re using.

- Even Heating: Ensure that heat is evenly distributed across the substrate. Uneven heating can result in inconsistent prints or issues with the transfer.

- Alignment: Carefully align your design on the substrate before pressing. Misalignment can result in off-center prints or cut-off parts of the design.

3. Print Quality

- Design Preparation: Use high-resolution images and ensure your design is properly sized for the substrate. This helps avoid pixelation and maintains clarity in your final print.

- Ink Quality: Use high-quality sublimation ink to ensure vibrant colors and good adhesion. Cheap or outdated ink can result in dull or faded prints.

4. Post-Print Care

- Cooling: Allow the substrate to cool down before handling it. This helps prevent the print from smudging or distorting.

- Storage: Store sublimated items in a cool, dry place to avoid any damage or degradation of the print. For items like apparel, avoid direct sunlight and excessive heat.

5. Troubleshooting Common Issues

- Fading Colors: If colors appear faded, check your ink quality and heat press settings. Also, make sure you’re using the correct settings for the substrate.

- Uneven Prints: Uneven prints can be due to inconsistent pressure or temperature. Ensure your heat press is calibrated correctly and the substrate is properly aligned.

- Adhesion Problems: If the ink isn’t adhering well, verify that you’re using a compatible substrate with the right coating and that your printer settings are correct.

Recommendations and Expert Advice

Drawing from my experiences and industry insights, here are some recommendations and expert tips to help you get the most out of your projects:

1. Product Recommendations

- For Mugs: Choose ceramic mugs with a high-quality coating for the best print results. Brands like Heatpressnation are known for their consistency and durability.

- For Apparel, Opt for 100% polyester or a high-polyester blend shirt for vibrant colors and durability. Companies like Amazon offer a variety of styles and sizes.

- For Phone Cases, Look for hard plastic cases with a smooth sublimation coating. Ensure the cases are compatible with your specific phone model to avoid fit issues.

- For Metal Plates: Select aluminum plates with a thick sublimation coating for sharp, long-lasting prints. Brands like Jpplus are reliable.

2. Expert Tips

- Test Different Blanks: Experiment with various blanks to find what works best for your needs. Testing helps you understand how different materials respond to sublimation and which ones yield the best results.

- Invest in Quality Equipment: Good printers, heat presses, and inks make a significant difference. Investing in high-quality equipment can save you time and frustration in the long run.

- Stay Updated on Trends: The sublimation industry evolves with new products and techniques. Stay informed by following industry blogs, joining online forums, and attending trade shows or webinars.

3. Handling and Care

- Proper Storage: To prevent damage, store your blanks and substrates in a cool, dry place. Avoid areas with high humidity or extreme temperatures.

- Regular Maintenance: Keep your printing equipment clean and well-maintained. Regular maintenance ensures consistent performance and high-quality prints. Check out the Troubleshooting Guide for Sublimation Printing.

4. Learning and Development

- Workshops and Courses: To enhance your sublimation skills, consider attending workshops or online courses. Learning from experts can provide valuable insights and improve your techniques.

- Join Online Communities: Engage with online sublimation communities to share experiences, ask questions, and get advice from other enthusiasts and professionals.

Sublimation Material List

1. Sublimation Printer

- Purpose: Transfers designs onto substrates using heat.

- Examples: Epson SureColor, Sawgrass Virtuoso, Ricoh SG series.

- Note: Must be compatible with sublimation inks (not all printers are).

2. Sublimation Inks

- Purpose: Specialty dyes that convert to gas under heat.

- Popular Brands: Cosmos Ink, Hiipoo, SubliJet.

3. Sublimation Paper

- Purpose: Holds ink until heat transfers it to the substrate.

- Key Features: High-release coating for vibrant results.

- Brands: TexPrint, Neenah, A-Sub.

4. Substrates (Items to Print On)

- Fabrics: Polyester or polyester-blend textiles (≥65% polyester for best results).

- Hard Substrates:

- Ceramics (mugs, plates, tiles with polymer coating).

- Metal (aluminum sheets, keychains, photo panels).

- Hardboard (signs, coasters).

- Phone cases, puzzles, coasters, ornaments.

5. Heat Press

- Types:

- Swing-Away/Clamshell: For flat items (T-shirts, fabrics).

- Mug Press: For cylindrical items (requires mug wraps).

- Hat Press: Curved surface for caps.

- 3D Vacuum Press: For uneven objects (like shoes).

6. Accessories

- Heat-Resistant Tape: Secures paper during transfers.

- Butcher Paper/Teflon Sheets: Protects the press and substrate.

- Cutting Tools: Cricut/Silhouette for precise designs.

- Lint Roller: Cleans fabrics before pressing.

- Heat Gun: Fixes ink on uneven surfaces (e.g., mugs).

7. Software & Color Management

- Design Software: Adobe Photoshop, Illustrator, Canva.

- RIP Software: Manages color accuracy (e.g., Wasatch, Ergosoft).

- Printer Calibration Tools: ICC profiles, colorimeters (X-Rite i1Studio).

8. Safety & Maintenance

- Protective Gear: Heat-resistant gloves, aprons.

- Cleaning Supplies: Printer cleaning kits, lint-free cloths.

- Ventilation: Ensure workspace is well-ventilated.

9. Suppliers of Sublimation Blanks

- Recommended: Conde Systems, Joto, Coastal Business Supplies.

10. Optional Extras

- Sublimation Oven: For bulk 3D items (tumblers, mugs).

- Cold Peel Paper: Prevents smudging on delicate substrates.

- Silicone Sheets: Protects heat press plates.

To achieve the best possible outcome, it’s important to choose and handle your materials carefully, whether you’re working on personalized gifts, promotional items, or custom apparel.

Remember, choosing blanks and substrates can make all the difference in the final product. With Subli Genius Print, you have the tools and expertise to make informed decisions and get the most out of your sublimation projects.

Have you encountered any specific challenges with sublimation blanks or substrates? Let’s discuss how Subli Genius Print can help you overcome them and enhance your printing results!

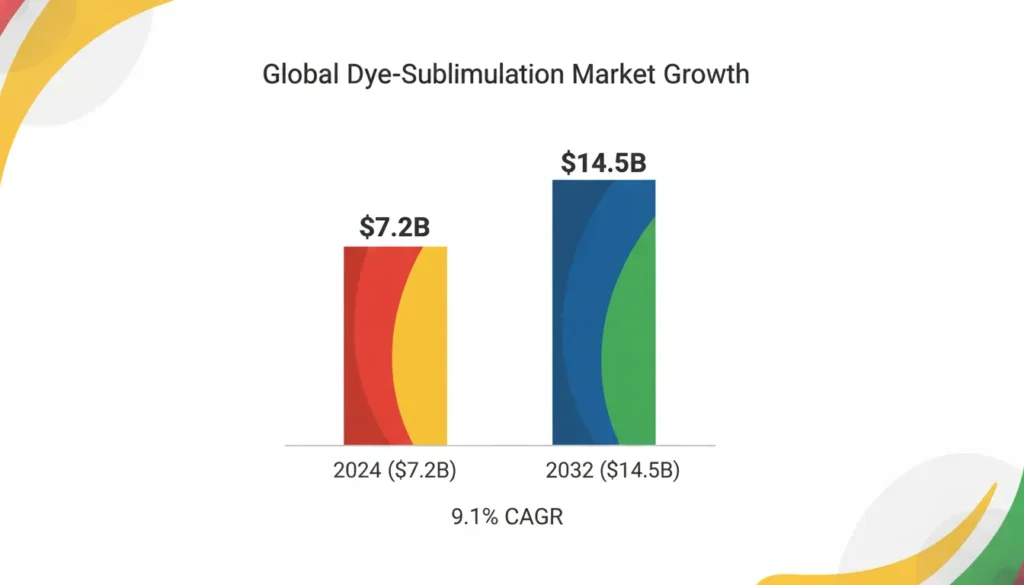

Global Dye-Sublimation Printing Market Growth (2024–2032)

Based on Allied Market Research (2024): Market projected to grow from $7.2 billion in 2024 to $14.5 billion by 2032 at a 9.1% CAGR.

Figure: Estimated dye-sublimation printing market growth (2024–2032). Data source: Allied Market Research, 2024.

| Year | Market Size (USD) |

|---|---|

| 2024 | $7.224 B |

| 2025 | $7.881 B |

| 2026 | $8.599 B |

| 2027 | $9.381 B |

| 2028 | $10.235 B |

| 2029 | $11.166 B |

| 2030 | $12.182 B |

| 2031 | $13.291 B |

| 2032 | $14.500 B |

6 Comments